GIDINGS&LEWIS 502-02769-00数据采集模块

1.产 品 资 料 介 绍:

GIDINGS&LEWIS 502-02769-00 数据采集模块:工业数据中枢的核心力量

多元应用领域

英文资料:

GIDINGS&LEWIS 502-02769-00 Data Acquisition Module: The Core Strength of Industrial Data Centers

In the complex ecosystem of industrial automation, data collection is a key link connecting physical devices and digital control systems, and its accuracy and efficiency directly affect the optimization of the entire production process and the formulation of management decisions. The GIDINGS&LEWIS 502-02769-00 data acquisition module has become an indispensable core component in many industrial scenarios due to its excellent performance and reliable quality.

Diversified application areas

In the field of CNC machine tools: During the operation of CNC equipment such as lathes, milling machines, boring machines, etc., the 502-02769-00 data acquisition module is responsible for real-time monitoring of key parameters of the equipment. It accurately collects the current and voltage signals of the motor to determine whether the motor is running stably and whether there is a risk of overload; At the same time, collect data related to the wear status of cutting tools, such as tool vibration frequency, cutting force, etc. Through the analysis of these data, CNC systems can adjust machining parameters in a timely manner, optimize tool paths, avoid the decrease in machining accuracy caused by excessive tool wear, ensure that part machining always maintains a high level of precision, and meet the strict requirements of the mechanical manufacturing industry for precision component machining.

Industrial automation production line: The automation production line covers multiple links such as assembly, sorting, conveying, and packaging, and the 502-02769-00 data acquisition module plays a key role in coordination and optimization. In the assembly process, it collects the position and attitude signals of the components detected by sensors to ensure precise grasping and installation of the robotic arm, improving assembly accuracy and efficiency. In the sorting system, feature data such as size, weight, and color of products are collected and analyzed to control the sorting mechanism to accurately classify the products. During the conveying process, monitor the speed, load, and other data of the conveyor belt to ensure smooth and accurate product transportation. In the packaging process, collect the operating parameters of packaging equipment, such as sealing temperature, packaging material tension, etc., to ensure packaging quality and efficiency, and improve the automation level and production stability of the entire production line.

Process control and monitoring system: The production processes in industries such as chemical, energy, and metallurgy require extremely high stability and safety. The 502-02769-00 data acquisition module plays a crucial role in such systems. In chemical production, it collects data such as temperature, pressure, liquid level, and flow rate of various materials in the reaction kettle to provide real-time information for the control system, ensuring that chemical reactions proceed under optimal conditions and avoiding safety accidents caused by abnormal parameters. In the energy industry, collecting operational data of power generation equipment, such as turbine speed, generator output voltage and current, helps with equipment maintenance and fault prediction, and improves the stability and reliability of energy production. In the metallurgical industry, collecting data on temperature distribution and charge composition of blast furnaces, optimizing smelting processes, and improving product quality and production efficiency.

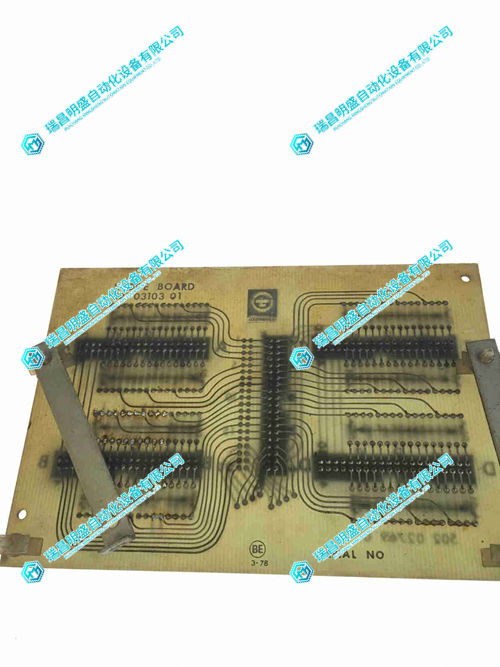

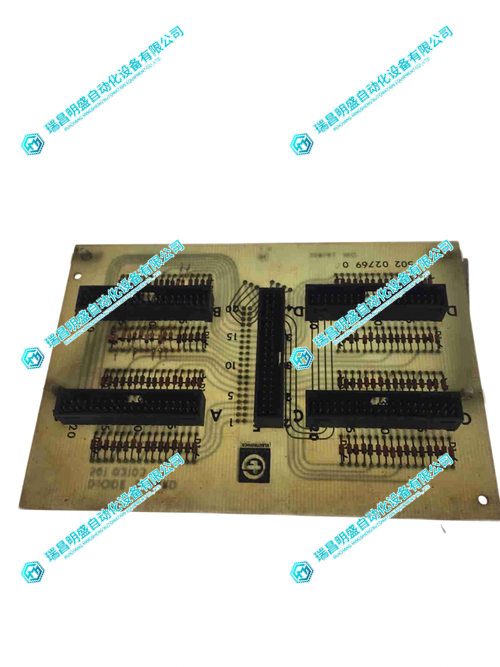

2.产 品 展 示

3.其他产品

BENTLY 3500/42M 176449-02卡件

DANAHER S21260-SRS伺服驱动器

ENTERASYS A2H254-16 P0973BK交换机

4.其他英文产品

PFTL101A 2.0KN 3BSE004172R1 Tension sensor

CMA120 3DDE300400 touch screen

CMA131 3DDE300411 Industrial control module

| UR6CH | CACR-SRA5AB | 859-8379-001B |

| UR6AV | CACR-UP60AAB | PRE-913425 |

| UR1800 | CACR-SR10B21SSY367 | EXP-MX |

| UNS0881a-P,V1 3BHB006338R0001 | CACR-SR05BC1ES-Y278 | 97-9525-20 |

| TRICONEX 3805H | CACR-02-SU3CY1 | EPC5A-CFB001 |

| TRICONEX 3625A | CACR-SR07BE12M | 851-8554-003E |

| TRICONEX 4351B | CACR-IR10SFB | EPC-9 |

| TRICONEX 3511 | CACR-HR10BB | 30705-004 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218