GIDINGS&LEWIS 502-03815-01 通信模块

1.产 品 资 料 介 绍:

Giddings & Lewis 502 - 03815 - 01 NSNP 通信模块

产品概述

技术特点

多协议支持

高速稳定

模块化设计

英文资料:

Giddings&Lewis 502-03815-01 NSNP Communication Module

Product Overview

In the complex architecture of industrial control systems, the Giddings&Lewis 502-03815-01 NSNP communication module plays an important role as a data exchange hub. It focuses on building high-speed and stable communication bridges between machine tool CNC systems, PLC control networks, and upper computers. It is usually installed inside the machine tool electrical control cabinet as a key interface between the CNC system and peripheral devices. This module undertakes multiple core tasks such as data acquisition, program transmission, and remote monitoring. Whether it is obtaining various real-time data from the operation of machine tools or accurately transmitting control instructions from the upper computer to the CNC system of machine tools, it can efficiently complete and ensure the smooth operation of the entire industrial control process.

Technical Features

Multi protocol support

Having strong protocol adaptation capabilities, it can seamlessly integrate with various common communication protocols in the industrial field, including serial communication protocols and industrial bus protocols. This means that regardless of the communication architecture in the industrial environment, the communication module can quickly integrate and achieve efficient data exchange with different devices. For example, in some traditional industrial production lines, serial communication protocols may still be used for basic communication between devices, and this module can be easily adapted; In modern Industry 4.0 factories, a large number of industrial bus protocols are used to achieve high-speed and efficient data transmission, which can also be perfectly compatible and greatly enhance its versatility in different industrial scenarios.

High speed stability

Committed to providing low latency data transmission services, this feature is particularly critical in the context of high real-time requirements in industrial control. In the process of machine tool machining, the CNC system needs to obtain real-time operating status data of various components of the machine tool in order to adjust machining parameters in a timely manner, ensuring machining accuracy and quality. This communication module can transmit these data from sensors and other devices to the CNC system at an extremely fast speed, while quickly transmitting the control instructions of the CNC system to the executing mechanism, ensuring the real-time and continuity of the entire machining process, effectively avoiding machining errors or equipment failures caused by data transmission delays.

modular design

Adopting advanced modular design concepts, this design brings many conveniences to the use of modules. In terms of equipment maintenance, when a module fails, only the corresponding module needs to be replaced directly, without the need for large-scale maintenance of the entire system, greatly reducing downtime and improving equipment availability. From the perspective of system expansion, if an enterprise needs to add new features or connect more devices in the later stage, simply adding relevant modules can achieve system expansion and upgrade, reducing the cost of system upgrade. Moreover, in the process of system integration, modular design enables the module to be quickly and conveniently integrated with other system components, improving the construction efficiency of the entire industrial control system.

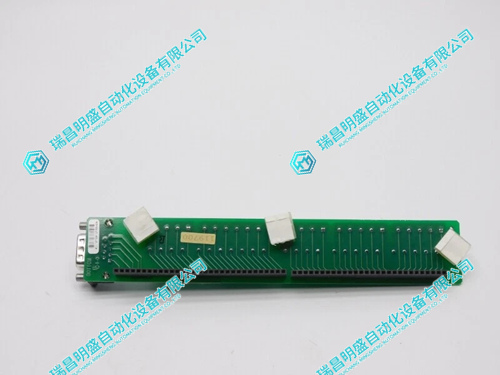

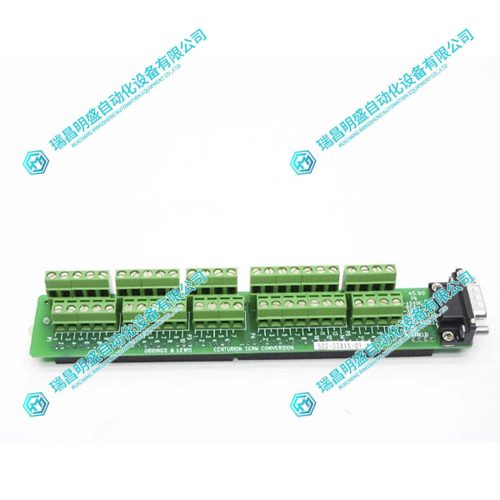

2.产 品 展 示

3.其他产品

AMAT 0010-22985驱动器组件

3BHE046836R0101 GFD563A101以太网端口模块

PPD512A10-150000 3BHE040375R1023控制器

4.其他英文产品

NI SCXI-1001 Ac machine box

SCXI-1102 Voltage input mold piece

NI SCXI-1102B Input module block

| PC832-XYZ-N | AMAT 0100-91040 | NFTP01 |

| PC832-XYZ-A | AMAT 0100-00120 | HESG332194R0001 70BK06A-E |

| PC832-111-N-4122-11 | AMAT 0100-09034 | HESG447440R0003 RS422/485 70BK03C-E |

| PC832-111-N | AMAT 0100-89004 | 57510001-AA DSCA114 ABB RS232C |

| PC832-102-N-4122-11 | AMAT 0100-35012 | 57350001-CU DSAV111 ABB |

| PC832-102-N | AMAT 0100-35126 | NTRO03 |

| PC832-001-T | AMAT 0100-09170 | 5712289-A DSAX 452 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218