1.产 品 资 料 介 绍:

67048-JH52-ABM流量控制阀 产品概述及应用领域

67048-JH52-ABM流量控制阀是一款具备高精度流量调节与稳定控制能力的核心流体控制组件,采用精密阀芯结构与多重密封设计,可实现对液体、气体等多种介质的精准流量管控,支持手动/自动调节模式,具备抗腐蚀、低泄漏、响应迅速的特性。其适配高压、高温等复杂工况,能稳定维持设定流量,广泛应用于对流量控制精度与运行可靠性有严苛要求的工业生产、环保处理等领域,核心应用如下:

一、石油化工与精细化工领域

核心场景:适配炼油厂输油管道、催化裂化装置的介质流量调节,精准控制原料输送速率保障反应稳定;应用于化工反应釜的原料进料与冷却水系统,通过精确调节试剂滴加量、冷却水流速优化反应条件,避免反应失控;可耐受酸碱等腐蚀性介质,适用于精细化工中催化剂添加、助剂投料等毫升级别精准计量工况,确保产品品质一致性。

二、生物制药与食品加工领域

核心场景:采用卫生级材质与无死角流道设计,适配生物制药发酵罐的流加补料系统,精准控制葡萄糖等营养物质的添加速率,维持最佳发酵环境提升产物得率,符合GMP标准;应用于食品饮料生产的原料输送、调配及杀菌工艺,精确调节物料流量保障产品配方一致性;可适配CIP在线清洗系统,避免交叉污染,满足食品医药行业卫生要求。

三、环保与水处理领域

核心场景:应用于污水处理厂曝气池的曝气流量调节、混凝剂投加系统,精准控制曝气量与药剂投加量,提升污水净化效率;适配工业废水处理的酸碱中和工艺,调节酸碱溶液添加流量确保出水水质达标;可用于城市供水、循环水系统,稳定管网流量避免动态失调,提升水资源利用效率。

四、通用工业与科研实验领域

核心场景:适配工业窑炉、换热器等设备的高温流体流量控制,保障换热效率与设备运行安全;作为科研实验设备的配套组件,用于微量试剂添加、气体流量调节等精密实验工况,确保实验数据的准确性与可重复性;具备良好的系统兼容性,可与DCS系统联动实现自动化控制,适配电子制造、新能源等行业的辅助流体控制需求。

67048-JH52-ABM流量控制阀 英文资料:

67048-JH52-ABM Flow Control Valve Product Overview and Application Fields

The 67048-JH52-ABM flow control valve is a core fluid control component with high-precision flow regulation and stable control capabilities. It adopts a precision valve core structure and multiple sealing designs, which can achieve precise flow control of various media such as liquids and gases. It supports manual/automatic adjustment modes and has the characteristics of corrosion resistance, low leakage, and rapid response. It is suitable for complex working conditions such as high pressure and high temperature, and can stably maintain the set flow rate. It is widely used in industrial production, environmental protection treatment and other fields that have strict requirements for flow control accuracy and operational reliability. The core applications are as follows:

1、 Petrochemical and fine chemical industries

Core scenario: Adapt to the medium flow regulation of oil pipelines and catalytic cracking units in refineries, accurately control the raw material transportation rate to ensure reaction stability; Applied to the raw material feeding and cooling water system of chemical reaction vessels, the reaction conditions are optimized by precisely adjusting the amount of reagent drops and the flow rate of cooling water to avoid reaction runaway; Capable of withstanding corrosive media such as acid and alkali, suitable for precise metering conditions at the milliliter level such as catalyst addition and additive feeding in fine chemicals, ensuring product quality consistency.

2、 Biopharmaceuticals and Food Processing

Core scenario: Adopting hygiene grade materials and no dead angle flow channel design, adapted to the flow feeding system of biopharmaceutical fermentation tanks, accurately controlling the addition rate of nutrients such as glucose, maintaining the best fermentation environment to improve product yield, and complying with GMP standards; Applied to raw material transportation, blending, and sterilization processes in food and beverage production, precise adjustment of material flow ensures product formula consistency; Compatible with CIP online cleaning system to avoid cross contamination and meet the hygiene requirements of the food and pharmaceutical industry.

3、 Environmental Protection and Water Treatment Field

Core scenario: Applied to the aeration flow regulation and coagulant dosing system of the aeration tank in sewage treatment plants, precise control of aeration and chemical dosage, and improvement of sewage purification efficiency; Adapt the acid-base neutralization process for industrial wastewater treatment, adjust the flow rate of acid-base solution addition to ensure that the effluent quality meets the standard; It can be used in urban water supply and circulating water systems to stabilize pipeline flow and avoid dynamic imbalance, thereby improving water resource utilization efficiency.

4、 General industrial and scientific research experimental fields

Core scenario: High temperature fluid flow control adapted to industrial kilns, heat exchangers, and other equipment to ensure heat transfer efficiency and equipment operation safety; As a supporting component of scientific research experimental equipment, it is used for precision experimental conditions such as adding trace reagents and adjusting gas flow rates, ensuring the accuracy and repeatability of experimental data; It has good system compatibility and can be linked with DCS systems to achieve automation control, adapting to the auxiliary fluid control needs of industries such as electronic manufacturing and new energy.

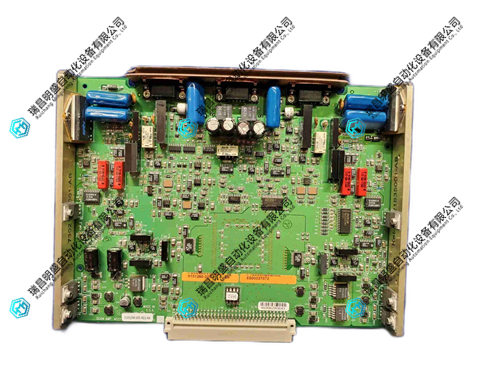

67048-JH52-ABM流量控制阀 产品展示

产品视频

3.其他产品

ABB 3BSE042235R1 PP845可编程控制器

ABB 3BSE042245R1 CB801电路板

Siemens 3VL9440-7DC30框架断路器

4.其他英文产品

FSEL003 F202174.02 Output structure module

IS200ISBBG2AAB Steam gas turbine module

SPAD346C3 Dc control module

| IC3600KMRA2 | 531X135PRGAJM1 | IC3600ADAD1 |

| IC3600KHVD | 531X135PRGAAM3 | IC3600ADAA1A |

| IC3600KHVB2 | 531X134EPRBNG1 | IC3600ACLS1B |

| IC3600KHDA2 | 531X134EPRBMG1 | IC3600AAMA1G1E |

| IC3600EPZU1F | 531X134EPRBJG1 | IC3600AAMA1G1B |

| IC3600EPZU1E | 531X134EPRBHG1 | IC3600AAMA1F1 |

| IC3600EPZU1D | 531X134EPRBGG1 | IC3600AAMA1E1 |

| HIEE300024R4 UAA326A04 | 531X134EPRBFG1 | IC3600AAMA1D1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218