1.产 品 资 料 介 绍:

853-235208-001热电偶模块作为工业级高精度温度采集核心单元,兼容K/J等多种类型热电偶,具备宽量程温度测量能力与优异的信号隔离抗干扰性能,支持标准工业通信协议,采用金属密封防护设计,可实现恶劣工况下的温度实时采集、信号转换与传输,能耐受高温、振动、粉尘及腐蚀性环境,广泛应用于工业热处理、能源电力、化工冶金等对温度监测精度要求严苛的领域,核心应用场景如下:

1. 工业自动化控制领域:适配PLC(可编程逻辑控制器)、变频器、伺服系统等工业控制核心设备,为其提供稳定的直流供电,保障自动化生产线、智能仓储设备、工业机器人等系统的连续精准运行,可耐受工业现场的电压波动、电磁干扰等复杂环境。

2. 玻璃与建材制造领域:应用于玻璃窑炉、浮法玻璃锡浴、陶瓷烧结窑等设备的温度监测,采集窑顶、窑底、供料道及烟道等关键部位的温度数据。具备耐高温腐蚀的防护设计,可减少耐火材料反应对测量精度的影响,为玻璃熔融、成型及建材烧结工艺的参数优化提供精准温度依据,保障产品成型质量与生产稳定性。

3. 石油化工与能源领域:用于石油炼化装置、化工反应釜、油气输送管线及电站锅炉的温度监测系统,实时采集反应过程、介质输送及燃烧工况的温度数据。符合防爆安全认证标准,可在易燃易爆、高湿度及腐蚀性环境下稳定工作,配合远程监控系统实现温度异常预警,保障化工生产与能源供应的安全性。

4. 航空航天与高端制造领域:适配航空发动机零部件热加工、航天器材料高温测试等场景,采集核心零部件在极端温度环境下的温度数据。具备快速响应特性(t90≤7s)与高测量重复性,能精准捕捉温度瞬时变化,为材料性能验证与零部件加工工艺优化提供可靠数据支撑,适配实验室与高端制造车间的严苛测试环境。

5. 食品医药与环保监测领域:应用于食品杀菌设备、医药冻干机的温度监测,确保生产过程符合卫生标准;同时适配工业废气处理装置、垃圾焚烧炉的烟道温度监测,为环保达标管控提供温度数据。具备信号隔离与抗干扰设计,可避免工业现场电磁干扰影响测量精度,保障生产安全与环保监测数据的准确性。

853-235208-001热电偶模块 英文资料:

The 853-235208-001 thermocouple module, as an industrial grade high-precision temperature acquisition core unit, is compatible with various types of thermocouples such as K/J. It has a wide range of temperature measurement capabilities and excellent signal isolation and anti-interference performance. It supports standard industrial communication protocols and adopts a metal sealed protection design, which can achieve real-time temperature acquisition, signal conversion and transmission under harsh working conditions. It can withstand high temperature, vibration, dust and corrosive environments and is widely used in industrial heat treatment, energy and power, chemical metallurgy and other fields that require strict temperature monitoring accuracy. The core application scenarios are as follows:

1. In the field of industrial automation control, it is suitable for industrial control core equipment such as PLC (Programmable Logic Controller), frequency converter, servo system, etc., providing stable DC power supply to ensure the continuous and accurate operation of automated production lines, intelligent warehousing equipment, industrial robots and other systems. It can withstand complex environments such as voltage fluctuations and electromagnetic interference in industrial sites.

2. In the field of glass and building materials manufacturing: applied to temperature monitoring of equipment such as glass kilns, float glass tin baths, ceramic sintering kilns, etc., collecting temperature data of key parts such as kiln roofs, kiln bottoms, feeding channels, and flues. The protective design with high temperature and corrosion resistance can reduce the impact of refractory material reactions on measurement accuracy, provide accurate temperature basis for parameter optimization of glass melting, forming and building material sintering processes, and ensure product forming quality and production stability.

3. In the field of petrochemicals and energy, it is used as a temperature monitoring system for petroleum refining equipment, chemical reaction vessels, oil and gas transmission pipelines, and power plant boilers, to collect real-time temperature data of reaction processes, medium transportation, and combustion conditions. Compliant with explosion-proof safety certification standards, it can work stably in flammable, explosive, high humidity, and corrosive environments, and cooperate with remote monitoring systems to achieve temperature anomaly warning, ensuring the safety of chemical production and energy supply.

4. Aerospace and high-end manufacturing field: adapted to scenarios such as thermal processing of aircraft engine components and high-temperature testing of spacecraft materials, collecting temperature data of core components in extreme temperature environments. Equipped with fast response characteristics (t90 ≤ 7s) and high measurement repeatability, it can accurately capture instantaneous temperature changes, providing reliable data support for material performance verification and component processing technology optimization, and adapting to the harsh testing environment of laboratories and high-end manufacturing workshops.

5. In the field of food, medicine, and environmental monitoring: applied to temperature monitoring of food sterilization equipment and pharmaceutical freeze-drying machines to ensure that the production process meets hygiene standards; Simultaneously adapting to industrial waste gas treatment equipment and flue gas temperature monitoring of garbage incinerators, providing temperature data for environmental compliance control. Equipped with signal isolation and anti-interference design, it can avoid the influence of electromagnetic interference on measurement accuracy in industrial sites, ensuring the accuracy of production safety and environmental monitoring data.

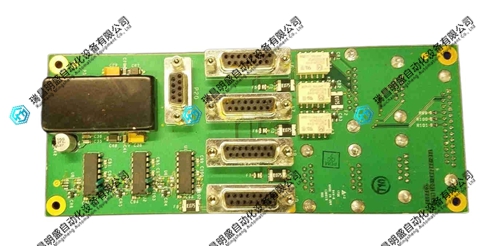

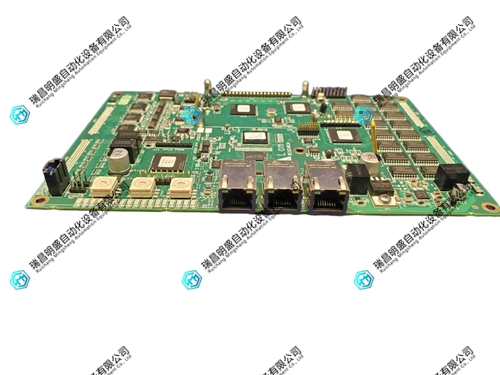

853-235208-001热电偶模块 产品展示

产品视频

3.其他产品

ABB CS513 3BSE000435R1通讯模块

ABB PCD235B101 3BHE032025R0101数字模块

BENTLY 135137-01震动模块

4.其他英文产品

HIMA F8651X processor module

RELIANCE 0-60063-1 60063-1 module

MVME-147A Control card

| AMAT 0041-39086 | 24210-10921-71 | SDCS-CON-4-COAT 3ADT313900 |

| AMAT 0100-77043 | 24210-11440-71 | ND32-5610 SPSV 3.2 92A8100263 |

| AMAT 0100-00127 | 24210-11442-71 | DSSR122 4899001-NK |

| AMAT 0100-90139 | 24210-12240-71 | 3503E |

| AMAT 0100-00133 | 24210-13130-71 | SLIO 02 |

| AMAT 0100-09302 | 24210-13153-71 | PFXC141 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218