1.产 品 资 料 介 绍:

1063708423-01控制单元作为工业级通用控制核心,采用高性能嵌入式处理架构,具备丰富的数字量/模拟量IO接口,支持Modbus、RS485等主流工业通讯协议,集成逻辑控制、数据采集与远程联动功能,采用工业级防护设计,可耐受-40℃至75℃宽温、电磁干扰及粉尘潮湿等恶劣工况,能实现复杂工业场景下的精准控制与稳定运行,广泛应用于能源电力、化工冶金、智慧城市等领域,核心应用场景如下:

1. 工业自动化控制领域:适配PLC(可编程逻辑控制器)、变频器、伺服系统等工业控制核心设备,为其提供稳定的直流供电,保障自动化生产线、智能仓储设备、工业机器人等系统的连续精准运行,可耐受工业现场的电压波动、电磁干扰等复杂环境。

2. 化工与油气储运领域:应用于油气长输管线、油库及精细化工生产系统,实现来油外输计量控制、储罐温度压力液位监控、工艺流程自动切换等功能。符合工业安全防护要求,可在易燃易爆、高湿度环境下稳定工作,通过精准的过程控制保障油气储运安全与化工生产工艺稳定性。

3. 智慧城市与市政管控领域:适配城市照明、自来水厂及污水处理厂自动化系统,通过经纬度与时控结合技术实现照明精准开关,或对水厂沉淀池、滤池、污水生化处理等环节进行自动联动控制。支持远程遥控与状态反馈,具备独立运行能力,通讯异常时可按预设逻辑执行,保障市政基础设施稳定运维。

4. 工业自动化生产线领域:用于汽车零部件组装、电子元件封装等产线的过程控制,对接PLC、变频器及传感器设备,实现多回路顺序控制、批处理控制及生产参数实时采集。支持高速信号处理与多设备协同联动,可优化生产节拍,减少物料损耗,耐受车间电压波动、粉尘等复杂工业环境。

5. 物流仓储与智能交通领域:适配立体仓库堆垛机调度、交叉带分拣机及轨道交通辅助设备控制,通过高速计数器处理光电信号,精准控制电机运行节奏与物料搬运轨迹。可集成WMS系统实现货位优化管理,具备强抗振动性能,保障物流分拣与交通辅助系统的高效精准运行。

1063708423-01控制单元 英文资料:

The 1063708423-01 control unit, as an industrial grade universal control core, adopts a high-performance embedded processing architecture and has rich digital/analog IO interfaces. It supports mainstream industrial communication protocols such as Modbus and RS485, integrates logic control, data acquisition, and remote linkage functions. It adopts industrial grade protection design and can withstand harsh working conditions such as -40 ℃ to 75 ℃ wide temperature range, electromagnetic interference, and dust humidity. It can achieve precise control and stable operation in complex industrial scenarios and is widely used in fields such as energy and power, chemical metallurgy, and smart cities. The core application scenarios are as follows:

1. In the field of industrial automation control, it is suitable for industrial control core equipment such as PLC (Programmable Logic Controller), frequency converter, servo system, etc., providing stable DC power supply to ensure the continuous and accurate operation of automated production lines, intelligent warehousing equipment, industrial robots and other systems. It can withstand complex environments such as voltage fluctuations and electromagnetic interference in industrial sites.

2. In the field of chemical engineering and oil and gas storage and transportation, it is applied to long-distance oil and gas pipelines, oil depots, and fine chemical production systems to achieve functions such as metering and control of incoming and outgoing oil, monitoring of tank temperature, pressure, and liquid level, and automatic switching of process flow. Compliant with industrial safety protection requirements, it can work stably in flammable, explosive, and high humidity environments, and ensure the safety of oil and gas storage and transportation as well as the stability of chemical production processes through precise process control.

3. In the field of smart cities and municipal control, it is suitable for urban lighting, water treatment plants, and sewage treatment plant automation systems. Through the combination of latitude, longitude, and time control technology, it can achieve precise lighting switching or automatic linkage control of water plant sedimentation tanks, filters, sewage biochemical treatment and other links. Support remote control and status feedback, with independent operation capability, can execute according to preset logic in case of communication abnormalities, ensuring stable operation and maintenance of municipal infrastructure.

4. In the field of industrial automation production lines: used for process control of automotive parts assembly, electronic component packaging and other production lines, connecting PLC, frequency converter and sensor equipment to achieve multi loop sequential control, batch processing control and real-time collection of production parameters. Supporting high-speed signal processing and multi device collaborative linkage, it can optimize production pace, reduce material loss, and withstand complex industrial environments such as workshop voltage fluctuations and dust.

5. In the field of logistics warehousing and intelligent transportation, it is suitable for the scheduling of three-dimensional warehouse stacker cranes, cross belt sorting machines, and control of rail transit auxiliary equipment. By processing photoelectric signals through high-speed counters, it accurately controls the motor operation rhythm and material handling trajectory. The WMS system can be integrated to achieve optimized management of cargo locations, with strong anti vibration performance, ensuring efficient and accurate operation of logistics sorting and traffic assistance systems.

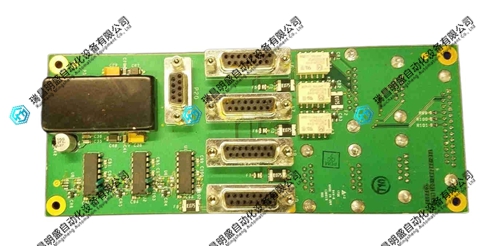

1063708423-01控制单元 产品展示

产品视频

3.其他产品

HIMA F3237 984323702安全模块

HIMA F3330 984333002安全模块

HIMA F6217 984621702

4.其他英文产品

YOKOGAWA NFAI143-H00 Logic module

YOKOGAWA SDV144-S13 Logic module

VME-7807RC-414001 Gas turbine card

| AMAT 0100-03622 | 24610-22641-71 | 3500/40M 135489-04 |

| AMAT 0100-09006 | 24630-11441-71 | CI867 3BSE043661R1 |

| AMAT 0100-00985 | 24701-13300-71 | 3500/40M 176449-01 |

| AMAT 0100-11018 | 24710-21442-71 | UFC921A101 3BHE024855R0101 |

| AMAT 0100-A1201 | 24750-11440-71 | 1800RZ21100A |

| AMAT 0100-00192 | 24750-11443-71 | F3503SILWORX |

| AMAT 0100-02797 | 24750-21440-71 | 3500/91-01-01-01 161216-01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218