TEL Tokyo Electron 2L81-050009-14控制主板卡件

1.产 品 资 料 介 绍:

中文资料:

TEL Tokyo Electron 2L81-050009-14 控制主板卡件(Control Main Board Module) 是TEL半导体设备中的核心控制单元,负责管理和协调设备的各项运行逻辑、工艺参数以及与其他子模块的通信,确保设备稳定高效运行。

一、基本信息

产品名称:控制主板卡件 / 主控板

产品型号:2L81-050009-14

制造商:Tokyo Electron Ltd.(TEL)

功能类别:主控制器板卡 / 逻辑处理模块

安装位置:设备控制柜内主控制架或主控机箱

二、主要功能

设备运行控制

负责执行设备的工艺流程控制指令,调度各子系统动作。

管理温度、压力、流量、真空等参数的自动调节。

数据采集与处理

收集来自传感器、数字量输入板、模拟量输入板等的信号数据。

实时监控设备状态,处理报警与异常事件。

通信接口

与上位系统(如工厂MES系统)及其他控制模块通信,支持工业现场总线协议。

实现模块间信息交换与同步。

安全与联锁管理

实现设备安全联锁逻辑,保障操作安全和工艺稳定。

监测安全门、紧急停止按钮、过载保护等安全设备状态。

三、典型应用领域

| 设备类型 | 作用说明 |

|---|---|

| Etcher 刻蚀设备 | 控制刻蚀过程的所有关键参数和步骤 |

| CVD/ALD 沉积设备 | 负责沉积工艺流程的实时监控和调整 |

| Track 涂胶显影设备 | 管理晶圆处理流程、机械运动与工艺联动 |

| 搬运系统(Transfer) | 控制机械手臂动作、路径规划与安全检测 |

英文资料:

The TEL Tokyo Electron 2L81-050009-14 Control Main Board Module is the core control unit in TEL semiconductor equipment, responsible for managing and coordinating various operational logics, process parameters, and communication with other sub modules to ensure stable and efficient operation of the equipment.

1、 Basic Information

Product Name: Control Motherboard Card/Main Control Board

Product model: 2L81-050009-14

Manufacturer: Tokyo Electron Ltd. (TEL)

Functional Category: Main Controller Board/Logic Processing Module

Installation location: Main control rack or main control chassis inside the equipment control cabinet

2、 Main functions

Equipment operation control

Responsible for executing process control instructions for equipment and scheduling actions of various subsystems.

Automatic adjustment of temperature, pressure, flow rate, vacuum and other parameters for management.

data acquisition and processing

Collect signal data from sensors, digital input boards, analog input boards, etc.

Real time monitoring of equipment status, handling alarms and abnormal events.

communication interface

Communicate with upper level systems (such as factory MES systems) and other control modules, supporting industrial fieldbus protocols.

Realize information exchange and synchronization between modules.

Safety and Interlocking Management

Implement equipment safety interlock logic to ensure operational safety and process stability.

Monitor the status of safety devices such as safety doors, emergency stop buttons, and overload protection.

3、 Typical application areas

Equipment type and function description

Etcher etching equipment controls all key parameters and steps of the etching process

The CVD/ALD deposition equipment is responsible for real-time monitoring and adjustment of the deposition process flow

Track coating and developing equipment management for wafer processing flow, mechanical motion, and process linkage

Transfer system controls the movement, path planning, and safety detection of robotic arms

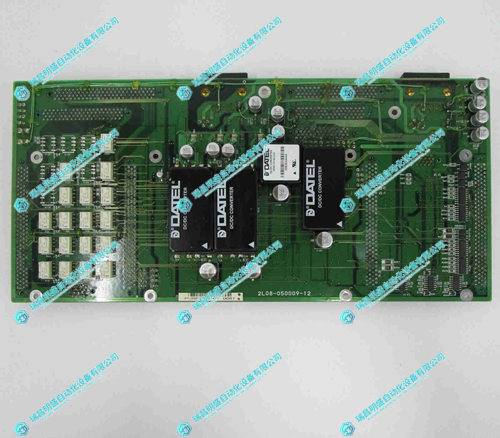

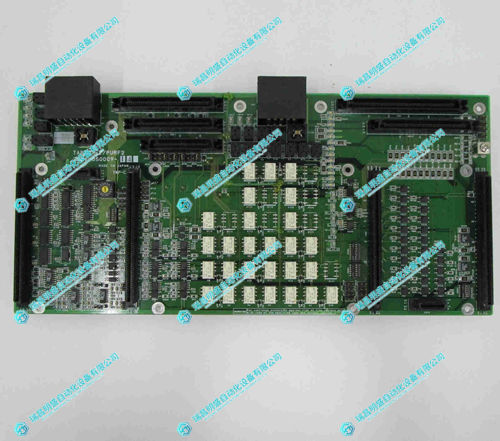

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB SB822 3BSE018172R1 rechargeable

ABB XVC768115 thyristor module

| PMB33E-10116-03 | IMCIS22 | 57160001-KG DSDP 160 |

| PMB33E-10116-02 | IMCOM03 | PFTL201CE 50.0KN 3BSE007913R51 |

| PMB33E-10116-01 | NTDO02 | 57160001-DF DSDI 301 |

| PMB33E-10116-00 | 70 FK01a | P21NSXC-LSS-NS-07 |

| PMB33E-10114-03 | NKTM010 | PMB33F-20114-03 |

| PMB33E-10114-02 | AMAT 0160-00018 | 57120001-NT DSAI 130H |

| PMB33E-10114-01 | NFTP01 | PWM3624-5437-7-1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218