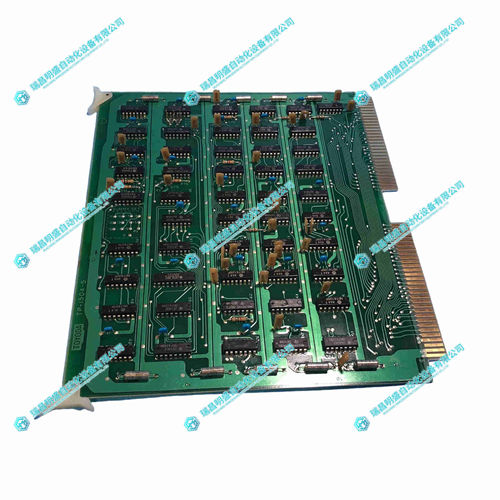

TOYOTA TP-1504-5 输入输出模块

1.产 品 资 料 介 绍:

- 机器人臂控制:实时接收机器人臂的位置、力度信号,快速输出指令调整动作,确保精准抓取和装配,提升效率与质量。

- 装配线协调:收集各工位状态信号,向执行器发送启停、调速等指令,减少生产停滞,触发安全防护,提高自动化和安全性。

- 多设备控制:对接数控机床、机械手、传送带等,转换传感器信号并输出控制指令,实现高精度加工装配。

- 复杂工序执行:凭借多点同步控制能力,协调多设备按序工作,保障复杂工序自动化高效进行。

- 设备协同:与分拣机器人、输送线等集成,接收货物信息并发送指令,实现快速分拣输送,提升物流效率。

- 数据监控:采集设备运行数据并上传,方便管理人员掌握状态、预判故障,保障系统稳定。

- 系统集成交互:与 PLC 等控制系统无缝集成,通过标准协议实现数据高速交互,确保工厂自动化系统高效运转。

- 监控与诊断:实时采集设备数据,异常时定位故障并报警,缩短维修时间,保障生产线稳定。

- 流程自动化:接入传感器和执行单元,输出控制信号驱动测试设备,同时采集数据,实现精密测试自动化。

- 效率与准确性:低延迟、高可靠性确保设备响应快、控制准,减少人工干预,提高测试效率和结果准确性。

Automobile production line

Robot arm control: Real time reception of position and force signals from the robot arm, rapid output of instructions to adjust actions, ensuring precise grasping and assembly, and improving efficiency and quality.

Assembly line coordination: Collect status signals from each workstation, send start stop, speed control and other instructions to actuators, reduce production stagnation, trigger safety protection, and improve automation and safety.

Mechanical processing and assembly equipment

Multi device control: docking with CNC machine tools, robotic arms, conveyor belts, etc., converting sensor signals and outputting control instructions to achieve high-precision machining and assembly.

Complex process execution: With the ability of multi-point synchronous control, coordinate multiple devices to work in sequence, ensuring efficient automation of complex processes.

Storage and Logistics System

Equipment collaboration: Integrated with sorting robots, conveyor lines, etc., it receives cargo information and sends instructions to achieve fast sorting and transportation, improving logistics efficiency.

Data monitoring: Collecting device operation data and uploading it, facilitating management personnel to grasp the status, predict faults, and ensure system stability.

Intelligent Manufacturing and Factory Automation

System Integration Interaction: Seamless integration with control systems such as PLC, achieving high-speed data exchange through standard protocols to ensure efficient operation of factory automation systems.

Monitoring and diagnosis: Real time collection of equipment data, locating faults and alerting in case of abnormalities, shortening maintenance time, and ensuring production line stability.

Testing and Inspection Equipment

Process automation: Connect sensors and execution units, output control signals to drive testing equipment, and collect data to achieve precision testing automation.

Efficiency and accuracy: Low latency and high reliability ensure fast equipment response and accurate control, reduce manual intervention, and improve testing efficiency and result accuracy.

In summary, the TOYOTA TP-1504-5 input/output module, with its high reliability, low latency, and powerful multi-point control capabilities, is the core input/output control unit in industrial production lines, contributing to the improvement of industrial automation levels.

2.产 品 展 示

3.其他产品

4.其他英文产品

ABB P8480 Analog Output Module

Radisys EPC-3307 processor board

| PXI-4462 | PFSK160A 3BSE009514R1 | SNAT603CNT SNAT 603 CNT |

| PXI-4461 | GESPAC GESMDC-1 | HIEE200130R2 AFC094AE01 |

| PXI-4110 | Gespac KP 0135.1 /KP0135.1 AB31J AMS-36-M | FAU810 |

| PXI-4060 | PPD113B03-26-100110 | 3500/65 |

| PXI-2598 | Gespac GESSIO-2 SIO-2 | 3500/92 136180-01 |

| PXI-2593 | Gespac GESPIA-2A | XV371A |

Contact: +86 15270269218