SANYO DENKI 3386-001007-11发动机组件

1.产 品 资 料 介 绍:

SANYO DENKI 3386-001007-11发动机组件 英文资料:

SANYO DENKI 3386-0001007-11 is a motor component designed specifically for precision equipment Z-axis transmission. It is fixed with 103H7126-17E1 components and has become a commonly used accessory for precision equipment Z-axis maintenance and installation due to its high adaptability and stable transmission performance. The following is a summary of its core features and practical points:

Exclusive Z-axis transmission positioning: This component is designed specifically for the Z-axis of equipment, with the core function of accurately controlling vertical movements such as lifting and positioning of the Z-axis. It can meet the strict requirements of precision machinery for Z-axis displacement accuracy and avoid offset errors in vertical movements.

Strong adaptability of fixed components: The 103H7126-17E1 component is clearly matched, which can minimize compatibility issues when different components are combined, ensure stable power transmission during Z-axis transmission, and reduce operational lag or accuracy deviation caused by component mismatch.

Suitable for precision equipment scenarios: In line with the high-speed and high-precision product characteristics of Shanyang SANMOTION servo system, it is commonly used in SMT surface mount machines, small precision machining machines, semiconductor testing equipment and other equipment that require Z-axis high-precision control to ensure the accuracy of welding, precision cutting, component mounting and other processes.

Integrated structure easy to assemble: As a complete motor component, it is highly likely to integrate the motor body, connecting bracket, and adaptive transmission structure, without the need for additional scattered accessories. When assembling, simply follow the conventional installation process of the Z-axis motor to complete the fixation and wiring, adapt to new equipment installation, and replace old components.

Industrial grade stability and durability: Continuing the high-quality craftsmanship of Shanyang Electric, the body is likely to be made of durable materials such as high-strength aluminum alloy, which can withstand continuous working conditions in industrial workshops, while resisting slight vibrations and dust interference, reducing the impact of frequent downtime maintenance on production efficiency.

Clear market pricing and circulation: As an industrial standard accessory, its market circulation status is clear, with a price tag of $2041, and it is mostly circulated in the form of original new products, which can meet the equipment maintenance and replacement needs with strict requirements for accessory quality.

Installation conforms to general specifications: Referring to the installation logic of similar Z-axis motors, corresponding motor mounting plates, synchronous belts, and other accessories need to be matched during installation. The assembly core is to ensure axis alignment and fix the wiring harness to avoid interference. After installation, assembly problems can be checked by testing the smoothness of Z-axis lifting and lowering.

Low power consumption and high stability: relying on the mature low-noise and low-energy technology of Shanyang Electric, this component has small vibration amplitude and low heat generation during operation. Under normal working conditions, it can maintain stable operation by relying on natural heat dissipation without the need for additional heat dissipation devices, reducing the overall energy consumption and operating noise of the equipment.

Troubleshooting is relatively simple: common problems often focus on wear and tear of transmission components or abnormal wiring. You can refer to the conventional testing methods for Z-axis motors, such as measuring the resistance between phase wires with an ohmmeter to determine the motor status, or checking whether the wiring harness connection is secure to troubleshoot signal transmission issues.

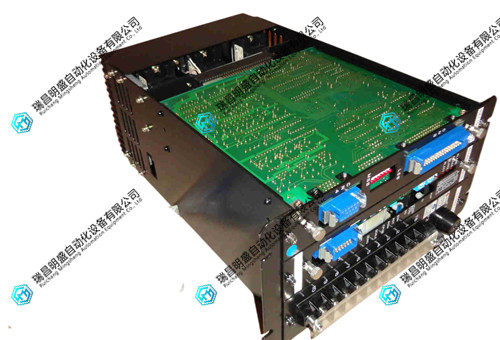

SANYO DENKI 3386-001007-11发动机组件 产品展示

产品视频

3.其他产品

YOKOGAWA SAI143-H53 模拟输入模块

BENTLY 3500/33-149986-01 速度监测器

GESAS CAN-DPV 数字放大器模块

4.其他英文产品

MKS EDGE3060A Generator

Honeywell CFHD-SBHM Controller Module

Woodward PEAK200-HVAC 8200-1501 Turbine Control Module

| IS220PPRAH1A IS220PPRAS18 | P8101Z22210020 | IMAS011 |

| IS220PHIRAH1A IS220PHRAH1B | SR10200-000000 | BRC300 |

| IS220PDOAH1A IS220PDOAH1B | PSR45A-112 | INICT03A |

| IS220PDIOH1A IS220PDIOH1B | SR10000-000000 | IMFEC12 |

| IS220PDIIH1A IS220PDIIH1B | SR06200-26404A | IEPMU01 |

| IS220PDIAH1A IS220PDIAH1B | SSS420SS400-10082/Receiver-10002 | IMCIS02 |

| IS220PCNOH1A IS220PCNOH1B | SERVOSTAR-343 | IMDS112 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218