AMAT Applied Materials 0040-32530冷盘组件

1.产 品 资 料 介 绍:

AMAT Applied Materials 0040-32530 冷盘组件

核心规格

功能特点

典型应用

安装与维护要点

AMAT Applied Materials 0040-32530冷盘组件 英文资料:

AMAT Applied Materials 0040-32530 Cold Plate Component

AMAT 0040-32530 cold plate component is a key thermal management component in semiconductor manufacturing equipment, mainly used for precise temperature control of wafers during the process. It achieves uniform cooling of wafers through refrigeration media or semiconductor refrigeration technology, ensuring process stability and repeatability.

Core specifications

Project specification remarks

Compatible with 200mm/300mm wafers on platforms such as Centura, Endura, P5000, etc

Temperature control range -20 ° C~80 ° C, accuracy up to ± 0.1 ° C

Cooling method: Water cooling/refrigerant circulation/semiconductor refrigeration depends on the specific model

Temperature uniformity ≤± 0.5 ° C on the entire wafer surface

Maximum vacuum degree 1 × 10 ⁻⁵ Torr suitable for high vacuum process environment

Material: 316L stainless steel/aluminum alloy, corrosion-resistant, low particle design

Interface type standard VCR/card sleeve interface for connecting cooling medium

Customized size design to fit specific equipment chambers

Features

High precision temperature control: using advanced temperature control algorithms to achieve precise control of wafer surface temperature

Excellent temperature uniformity: Optimized cooling channel design ensures consistent temperature across the entire wafer surface

High vacuum compatibility: Special sealing design to meet the requirements of high vacuum environments

Corrosion resistant design: using corrosion-resistant materials suitable for various process environments

Low particle generation: special surface treatment to reduce the risk of particle contamination

Modular design: easy to maintain and replace, reducing equipment downtime

Typical Applications

Temperature control of wafers in etching process

Substrate cooling during thin film deposition process

Temperature regulation of wafers before ion implantation

Various semiconductor manufacturing processes that require precise temperature control

Key points for installation and maintenance

Installation precautions:

Ensure that the sealing surface between the cold plate and the chamber is clean and free of scratches

Tighten the connecting bolts according to the prescribed torque

Check the sealing status of the cooling medium interface

Usage suggestions:

Confirm that the flow rate and pressure of the cooling medium are normal before starting

Avoid rapid temperature changes and protect seals

Regularly check temperature uniformity

Maintenance cycle:

Check the sealing condition every 6 months

Conduct a comprehensive performance test once a year

replace vulnerable parts according to the equipment manual requirements

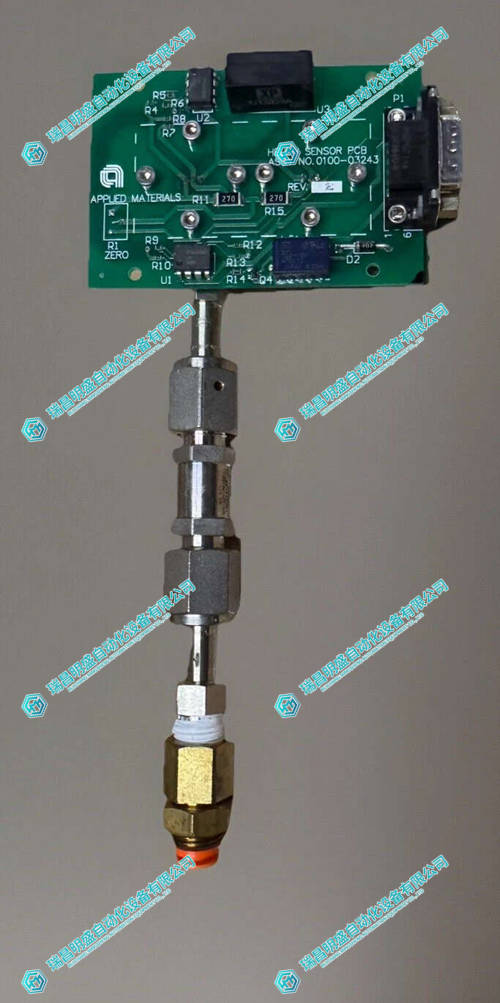

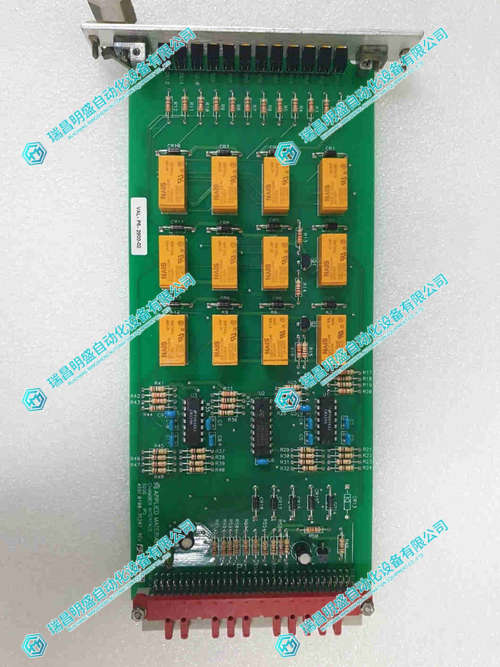

AMAT Applied Materials 0040-32530冷盘组件板 产品展示

产品视频

3.其他产品

Alcatel-Lucent AE-37Y-2 - MDR8000控制器模块板

Alcatel-Lucent 644-0092-002控制器模块

Alcatel-Lucent 622-8180-001网络适配器

4.其他英文产品

ABB 3BSE017457R1 Drive output module

ABB 5SDD1060F0001 3BHL001863P0001 module

ABB 5SGX1060H0003 Drive input module

| R46HMNA-R2-NS-NV-00 | R32GEN0-R2-NS-VS-00 | R43-HSNA-TS-EF-NV-02 |

| R46HENA-TS-NS-NV-00 | R43GCAA-R2-NS-VS-00 | R34JENC-TS-NS-NV-00 |

| R46HENA-R2-NS-VS-00 | R32SSNA-R2-NS-NV-10 | R33HENA-R2-NS-NV-00 |

| R46HENA-R2-NS-NV-00 | R24HENA-R1-NS-NV-01 | R32GEAC-R2-NS-NV-00 |

| R46HCNA-R2-NS-NV-00 | R43GEBA-TS-NS-NV-00 | S21GNNA-RNNL-00 |

| R46HCAA-R2-NS-VS-00 | R43HCBA-R2-NS-VS-00 | R35GENH-R2-NS-NV-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218