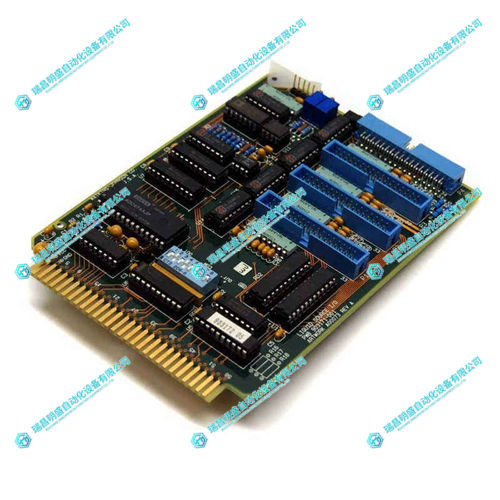

AMAT Applied Materials 9090-00962真空控制底盘

1.产 品 资 料 介 绍:

AMAT Applied Materials 9090-00962真空控制底盘 英文资料:

AMAT Applied Materials 9090-00962 vacuum controlled chassis is mainly used in the semiconductor manufacturing field, as follows:

Thin film deposition: In thin film deposition processes such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and atomic layer deposition (ALD), precise control of the vacuum environment is required to ensure the uniformity and quality of the thin film. This vacuum control chassis can provide stable vacuum conditions, ensuring that gas molecules can accurately deposit on the wafer surface, forming high-quality thin films, such as insulation layers, conductive layers, etc. in semiconductor devices.

Etching: The etching process removes unwanted materials from the surface of the wafer to form precise circuit patterns. AMAT 9090-00962 vacuum control chassis can adjust process pressure to achieve precise material removal. By cooperating with capacitive vacuum gauges, Pirani vacuum gauges, etc., it ensures consistent etching and high process repeatability.

Photolithography: Vacuum control is crucial for maintaining the stability and accuracy of lithography equipment in the lithography process. The vacuum control chassis ensures precise pressure control within the process system, and the vacuum components ensure leak free connections, which helps improve the stability of photolithography processes and the accuracy of pattern transfer, thereby affecting the performance and size reduction of semiconductor devices.

Crystal growth: In the process of semiconductor crystal growth, such as silicon crystal drawing, precise control of the process pressure inside the growth chamber is required to grow flawless crystals. AMAT's vacuum controlled chassis can provide a stable vacuum environment for crystal growth, which helps improve the quality and purity of semiconductor materials.

Advanced packaging: Advanced packaging processes have extremely strict precision requirements for vacuum control systems, and any small error may affect the performance of the final product. The AMAT 9090-00962 vacuum control chassis can be used for advanced packaging processes such as vacuum welding and vacuum sealing, ensuring the reliability and consistency of the packaging process.

AMAT Applied Materials 9090-00962真空控制底盘 产品展示

产品视频

3.其他产品

BENTLY 3500/33 149992-01 输入输出模块

ABB ACS-RTAC-01 64610805接口模块

NI CPCI-3840 单板计算机

4.其他英文产品

BENTLY 135473-01 Monitor module

BENTLY 135489-04 Temperature module

BENTLY 136711-01 Temperature module

| 745-W2-P15-G1-LO-A-R | 8030-RIM-331 | X-FTA 003 02L 02R |

| 735-5-5-LO-485 | 8030-RIM-25 | X-FTA 002 02L 02R |

| 735-5-5-HI-485 | 8030-RIM-144 | X-FTA 002 01L 01R |

| 735-5-5-125-485-DEMO | 8030-RIM-143 | X-FTA 001 02L |

| 735-5-1-LO-485 | 8030-RIM-141 | X-FTA 001 01L |

| 735-5-1-HI-485 | 8030-ROM-141 | X-MIO 7/6 01 |

| 720-23743-000 | 8030-ROM-131 | X-HART 32 01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218