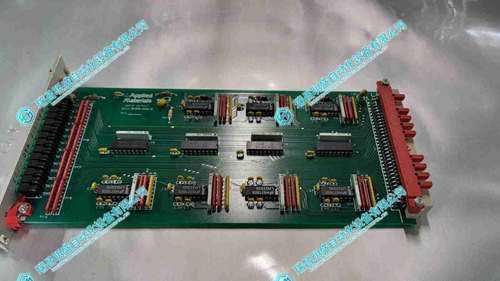

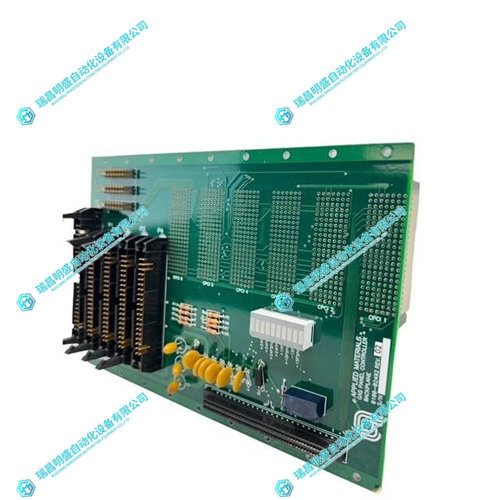

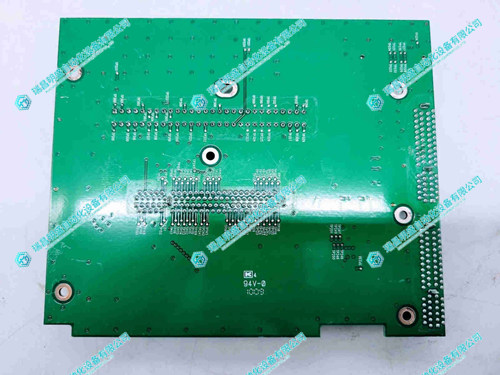

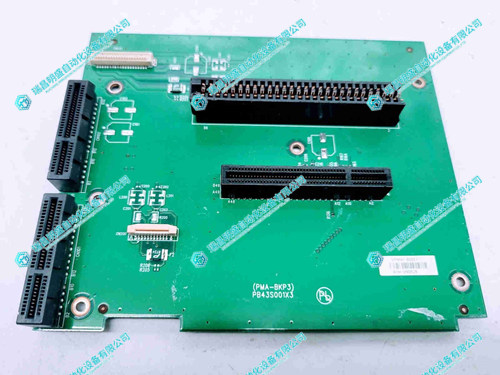

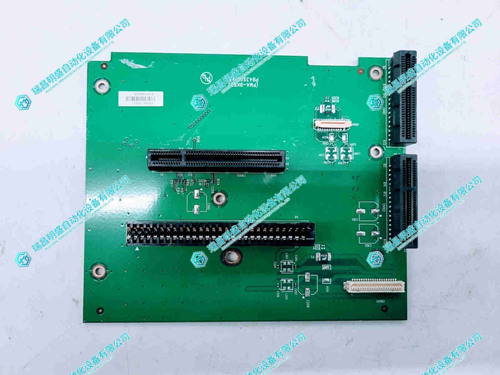

AMAT Applied Materials PAM-BKP3印刷电路板

1.产 品 资 料 介 绍:

- 高密度布线与信号优化:采用多层板设计(推测为 8-12 层),布线密度达 180 线 / 英寸,可集成大量精密元器件(如贴片电阻、电容、芯片),同时通过阻抗匹配设计(特性阻抗控制在 50Ω±10%、75Ω±10%),优化高频信号(如 100MHz 以上的控制信号、传感器采集信号)传输性能,减少信号反射与衰减,确保半导体设备工艺参数(如温度、压力)传输误差≤0.1%,避免因信号失真导致的工艺偏差。

- 多信号类型兼容集成:支持数字信号(如 TTL/CMOS 电平信号)、模拟信号(如 4-20mA 电流信号、0-10V 电压信号)与功率信号(如驱动电机的高电压信号)的同步传输,不同类型信号线路间设置隔离带(宽度≥0.2mm)与接地屏蔽层,隔离度≥60dB,防止信号串扰,保障设备控制系统(如 PLC)、执行机构(如伺服电机)、监测模块(如热电偶)之间的信号独立稳定传输。

- 冗余设计提升可靠性:关键电路(如电源供电电路、核心控制芯片连接电路)采用冗余设计,配备备用线路与元器件,当主电路出现故障时,冗余电路可在 10ms 内自动切换,确保半导体设备核心功能(如晶圆传输、工艺腔温度控制)不中断,避免因电路板故障导致的设备停机与晶圆报废,提升设备运行可靠性。

- 基板材质与性能:采用 FR-4 环氧树脂玻璃布基板(Tg 值≥170℃),具备优异的耐高温性能,在半导体设备高温区域(如靠近加热腔的 60-80℃环境)长期运行时,基板热变形量≤0.2%,无开裂、分层现象;同时基板介电常数稳定(1MHz 下介电常数≤4.5),介电损耗≤0.02,确保高频信号传输性能稳定,不受温度变化影响。

- 导体与涂层工艺:导体采用电解铜箔(厚度≥35μm),铜箔附着力≥1.5N/mm,经过沉金工艺处理(金层厚度≥2μm),具备优异的导电性(电阻率≤1.7×10⁻⁸Ω・m)与抗腐蚀性能,可抵御洁净车间微量腐蚀性气体(如刻蚀工艺中的氟化物残留)侵蚀,避免导体氧化导致的接触电阻增大;表面涂层采用阻焊油墨(绿油),绝缘性能优异(击穿电压≥20kV/mm),同时具备防刮擦、防指纹特性,便于设备维护时的操作。

AMAT Applied Materials PAM-BKP3印刷电路板 英文资料:

1、 High precision circuit design: adapted to the signal transmission requirements of semiconductor equipment

As the "circuit hub" of semiconductor equipment, PAM-BKP3 printed circuit board takes high-precision circuit layout as its core, meeting the stable transmission and precise control requirements of complex signals in equipment:

High density wiring and signal optimization: Adopting a multi-layer board design (estimated to be 8-12 layers), the wiring density reaches 180 wires/inch, which can integrate a large number of precision components (such as chip resistors, capacitors, chips). At the same time, through impedance matching design (characteristic impedance controlled at 50 Ω± 10%, 75 Ω± 10%), the transmission performance of high-frequency signals (such as control signals above 100MHz and sensor acquisition signals) is optimized, reducing signal reflection and attenuation, ensuring that the transmission error of semiconductor equipment process parameters (such as temperature and pressure) is ≤ 0.1%, and avoiding process deviations caused by signal distortion.

Multi signal type compatible integration: supports synchronous transmission of digital signals (such as TTL/CMOS level signals), analog signals (such as 4-20mA current signals, 0-10V voltage signals), and power signals (such as high voltage signals for driving motors). Isolation tapes (width ≥ 0.2mm) and grounding shielding layers are set between different types of signal lines, with an isolation degree ≥ 60dB, to prevent signal crosstalk and ensure independent and stable signal transmission between equipment control systems (such as PLC), actuators (such as servo motors), and monitoring modules (such as thermocouples).

Redundancy design enhances reliability: Key circuits (such as power supply circuits and core control chip connection circuits) adopt redundancy design, equipped with backup lines and components. When the main circuit fails, the redundant circuit can automatically switch within 10ms, ensuring that the core functions of semiconductor equipment (such as wafer transfer and process chamber temperature control) are not interrupted, avoiding equipment downtime and wafer scrap caused by circuit board failures, and improving equipment operation reliability.

2、 High durability material selection: ensuring long-term stable operation

Based on AMAT's specialized material standards for the semiconductor industry, PAM-BKP3 printed circuit boards prioritize durability and stability in material selection to extend their lifespan

Substrate material and performance: FR-4 epoxy resin glass cloth substrate (Tg value ≥ 170 ℃) is used, which has excellent high temperature resistance. When operating in high-temperature areas of semiconductor equipment (such as 60-80 ℃ environment near the heating chamber) for a long time, the thermal deformation of the substrate is ≤ 0.2%, and there is no cracking or delamination phenomenon; At the same time, the substrate has a stable dielectric constant (dielectric constant ≤ 4.5 at 1MHz) and a dielectric loss ≤ 0.02, ensuring stable high-frequency signal transmission performance and not affected by temperature changes.

Conductor and coating process: The conductor is made of electrolytic copper foil (thickness ≥ 35 μ m), with a copper foil adhesion of ≥ 1.5N/mm. After being treated with gold deposition process (gold layer thickness ≥ 2 μ m), it has excellent conductivity (resistivity ≤ 1.7 × 10 ΩΩ· m) and corrosion resistance, and can resist the erosion of trace corrosive gases in clean workshops (such as fluoride residues in etching process)

AMAT Applied Materials PAM-BKP3印刷电路板 产品展示

产品视频

3.其他产品

MC-4/11/03/400 伺服驱动器

MOISTURE.IQ-1-6-1-1-1-0-0 分析仪

XV-440-10TVB-1-50 触摸屏

4.其他英文产品

EATON MPB2-TP Connect the module

SCHROFF MPS022 13100-203 module

WATLOWANAFZE PPC-TB50 module

| 710-651090-20 | 8055-SCP-655 | 820-06553-000 |

| 710-650879-20 | 8055-SCP-654 | 4007-001-0089 |

| 710-650204-20 | 8055-SCP-453 | 710-650074-20 |

| 710-650201-20 | 8055-SCP-654R | F31X170TBSADG1 |

| 710-650094-20 | 8030-CRM-230 | 740-607108-005 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218