AMAT Applied Materials 0150-09228控制器模块

1.产 品 资 料 介 绍:

- 多核处理器与算力配置

- 实时操作系统与控制算法

- 高速数据存储与读写

AMAT Applied Materials 0150-09228控制器模块 英文资料:

1、 High performance core computing power: supporting real-time control of semiconductor processes

As the "control brain" of semiconductor devices, the 0150-09228 controller module, with its powerful computing power as its core, provides computing power support for parameter calculation and timing control of complex processes such as etching and deposition, ensuring high-precision and stable operation of the equipment

Multi core processors and computing power configuration

Equipped with industrial grade high-performance multi-core processors (presumably Intel Xeon E-2300 series or AMD Ryzen Embedded V3000 series), with a core count of ≥ 6, a clock frequency of ≥ 3.0GHz, and a turbo frequency of up to 4.5GHz, integrated with high-performance GPUs (such as Intel UHD Graphics P630) and hardware acceleration modules (such as FPGA co processors), the overall computing power reaches over 200 GFLOPS; Supports 8GB-32GB DDR4 ECC memory (memory bandwidth ≥ 25.6GB/s), capable of running multiple tasks such as process control programs, data acquisition and analysis, and device status monitoring simultaneously. The task switching delay is ≤ 50 μ s, meeting the strict requirements for real-time and multi-threaded processing in 24-hour continuous operation of semiconductor devices, and avoiding process lag or parameter calculation deviation caused by insufficient computing power.

Real time operating systems and control algorithms

Supports industrial grade real-time operating systems (RTOS) such as VxWorks and QNX, and is compatible with Linux embedded systems. The system scheduling cycle is ≤ 1ms, and the interrupt response time is ≤ 10 μ s. It can accurately execute process timing control, such as the "grabbing translation placement" action timing of the wafer transfer robotic arm and the power adjustment rhythm of the RF power supply, to ensure that the process step error is ≤ 0.05s. The built-in AMAT self-developed adaptive PID control algorithm can automatically optimize control parameters according to process parameter fluctuations (such as chamber pressure and temperature changes), with a control accuracy of ± 0.1% F.S., to avoid process instability caused by external interference and ensure wafer processing yield.

High speed data storage and read-write

Equipped with dual storage interfaces: one M.2 NVMe interface (supporting 1TB-4TB high-speed solid-state drives with read and write speeds ≥ 3500MB/s) and one SATA III interface (supporting 2TB-8TB mechanical hard drives or solid-state drives), which can meet the long-term storage needs of equipment process data and operation logs; Built in 16GB onboard Flash storage for storing system firmware and critical process recipes, with a read speed of ≥ 500MB/s, ensuring device startup time ≤ 30 seconds, and avoiding device startup delay caused by slow storage read and write.

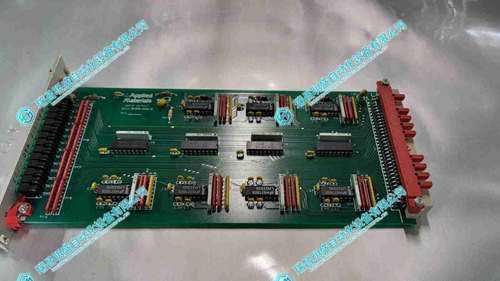

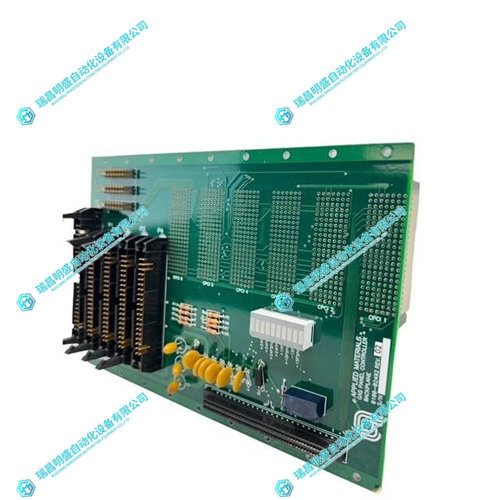

AMAT Applied Materials 0150-09228控制器模块 产品展示

产品视频

3.其他产品

REXROTH HNC100 SYHNC100-BLA-23/W-08-C-0-E23-A014 独立控制器

REXROTH PPC-R22.1N-T-NN-P1-NN-FW 伺服控制器

Teknic SST-1500-XCX 数字伺服驱动器

4.其他英文产品

ICS TRIPLEX T8461 industrial module

KOLLMORGEN CB06561 PRD-B040SSlz-62 Servo module

GE SR469-P5-HI-A1-E Relay module

| 6ES5421-8MA12 | CACR-SR07AY1SRY32 | 6DD3440-0AB2 |

| 6ES5-420-7LA11 | 6SC6508-0AA02 | 6DD3440-0AB0 |

| 6ES5420-7LA11 | CACR-PR03AE3ER | 6DD1843-0AB0 |

| 6ES5420-4UA14 | CACR-IR050505FC | 6AV30101DK00 |

| 6ES54201BA11 | CACR-SR30SB1AFY124 | 6DD1843-0AA0 |

| 6ES5405-7AB21 | CACR-HR05BAB12 | 6DD2920-3AW4 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218