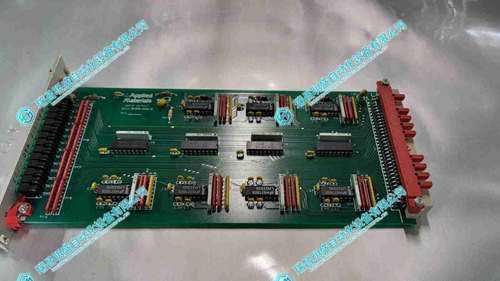

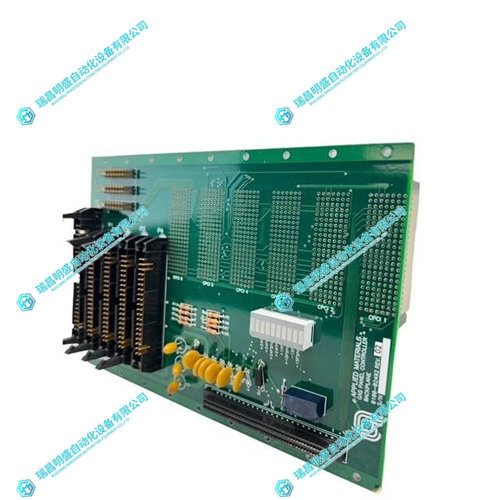

AMAT Applied Materials MQDB011AAD03交流电伺服驱动器

1.产 品 资 料 介 绍:

- 多维度精准控制能力

- 位置控制:搭配绝对值编码器(分辨率≥17 位),定位精度达 ±0.1°,重复定位误差≤±3μm,可满足光刻设备工作台、晶圆对准平台的纳米级定位需求;

- 速度控制:转速调节范围 0-3000rpm,速度波动率≤±0.1%,在晶圆传输机械臂高速运行(2000rpm)与低速微调(5rpm)切换时,无速度冲击,避免晶圆晃动或掉落;

- 力矩控制:力矩输出范围 0-10Nm,控制精度 ±1% F.S.,可精准调控机械臂夹取晶圆的力度(通常维持在 0.5-2Nm),防止夹伤晶圆边缘或因力度不足导致滑落。

- 高速响应与动态调节

- 多反馈模式适配

AMAT Applied Materials MQDB011AAD03交流电伺服驱动器 英文资料:

High precision motion drive: supporting precise operation of semiconductor equipment

As the "power control core" of semiconductor equipment, MQDB011AAD03 servo driver takes millisecond level response and micrometer level positioning accuracy as its core, ensuring the precise execution of key actions such as wafer transfer and process chamber positioning, directly affecting chip manufacturing yield:

Multi dimensional precise control capability

Supports three core control modes: position, speed, and torque, adapting to different process scenario requirements:

Position control: Equipped with an absolute value encoder (resolution ≥ 17 bits), the positioning accuracy reaches ± 0.1 °, and the repeated positioning error is ≤± 3 μ m, which can meet the nanoscale positioning requirements of lithography equipment workbenches and wafer alignment platforms;

Speed control: The speed adjustment range is 0-3000rpm, with a speed fluctuation rate of ≤± 0.1%. When switching between high-speed operation (2000rpm) and low-speed fine-tuning (5rpm) of the wafer transfer robotic arm, there is no speed impact to avoid wafer shaking or falling;

Torque control: The torque output range is 0-10Nm, with a control accuracy of ± 1% F.S. It can accurately regulate the force of the robotic arm gripping the wafer (usually maintained at 0.5-2Nm), preventing damage to the wafer edge or slipping due to insufficient force.

High speed response and dynamic adjustment

Adopting a dual core architecture of digital signal processor (DSP) and FPGA, with a control cycle of ≤ 100 μ s and a dynamic response time of ≤ 5ms, it can quickly compensate for load fluctuations - for example, when the robotic arm grabs a wafer (load increases by 0.5kg), the driver completes torque adjustment within 10ms to ensure speed stability; Equipped with adaptive PID algorithm, it can automatically optimize control parameters according to load changes. In frequent start stop scenarios such as etching equipment chamber door switches, the start stop impact is ≤ 5m/s ², extending the service life of mechanical components.

Multi feedback mode adaptation

Compatible with digital Hall, incremental, and absolute encoder signals, supports 1Vpp sine wave signal acquisition, feedback signal update frequency ≥ 10kHz, and can capture real-time data such as motor speed and position deviation; High speed interaction between feedback data and the upper computer is achieved through CANopen bus, with a data transmission delay of ≤ 1ms, providing precise synchronization basis for multi axis collaborative control.

AMAT Applied Materials MQDB011AAD03交流电伺服驱动器 产品展示

产品视频

3.其他产品

LD800HSEEX 3BSE073314R1控制器模块

Siemens 6ES7307-1EA01-0AA0 电源模块

1C31197G01 定位器模块

4.其他英文产品

HIMA F6217 Input module

HIMA F6705 Output module

HIMA F7133 Output module

| 6ES58941MA040UD3 | CACR-SR05SB1BFY187 | 504802-008 |

| 6ES58940MA040UG6 | CACR-SR-20SB1BFY118 | UIMC-III-1 |

| 6ES58640MA040UG4 | CACR-SR15BE12FY8 | 46088203 |

| 6ES58487DA040UG4 | CACR-UP50AABY45 | 067-10100-0006 |

| 6ES58427CB010KL1 | CACR-PR03BC3CSY30 | 851-8833-001A |

| 6ES5835-8MD01 | CACR-IR30SFD | SBC486DX66 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218