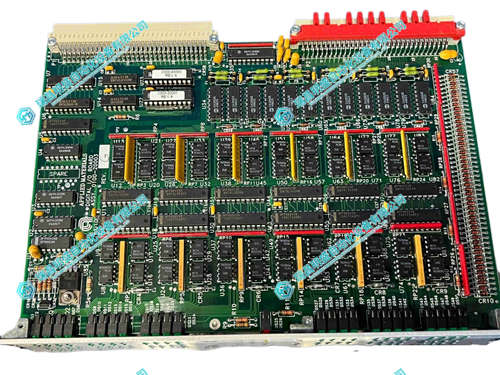

AMAT Applied Materials 0190-42550匹配网络模块

1.产 品 资 料 介 绍:

AMAT Applied Materials 0190-42550匹配网络模块 英文资料:

1. High-speed and precise signal matching and transmission capability

As the core hub for the interconnection of semiconductor devices, the core advantage of 0190-42550 lies in the signal synchronization accuracy adapted to nanoscale processes. Referring to the technical requirements of the AMAT Integrated Production System (IMS), this module is highly likely to adopt adaptive signal equalization technology, which can perform ±0.1ns delay calibration on high-frequency analog signals generated by etching machines, thin film deposition equipment, etc. Combined with a 16-bit high-speed AD/DA conversion chip, Achieve distortion-free signal transmission within the 0-1 GHZ bandwidth. In response to the interface differences of various devices, the module is equipped with 8 sets of configurable matching circuits, supporting adaptive impedance adjustment of 50Ω/75Ω. It can precisely meet the transmission requirements of RF signals and PLC control signals for PVD and CVD devices, solving the problem of signal attenuation in multi-device collaboration.

Second, full-scenario system compatibility and interconnection capabilities

To support the interconnection requirements of AMAT full-process equipment, this module features seamless cross-platform integration. At the hardware level, dual industrial Ethernet interfaces of EtherCAT and Profinet are reserved, with a communication cycle as low as 250μs. It can be directly connected to the AMAT FabWorks production execution system to achieve real-time parameter synchronization with core devices such as Reflexion CMP equipment and Centris etching systems. The software level is compatible with the SEMI E134 communication protocol, supporting standardized data interaction with third-party devices. Meanwhile, it is equipped with an AMAT dedicated communication protocol parsing module, which can directly read the deposition process parameters of the Producer CVD system without the need for additional gateway configuration. In addition, the module supports the storage of over 1,000 sets of device configuration files and can quickly switch to adapt to different process device linkage scenarios.

Iii. Specialized Protection Design for Harsh Environments

In response to the complex environment of semiconductor cleanrooms and equipment clusters, the stability design of the module highlights anti-interference and clean compatibility. It adopts a fully metal shielding housing and an internal three-layer PCB shielding structure, achieving an electromagnetic interference suppression capability of over 110dB, effectively resisting the strong electromagnetic radiation generated by the RF power supply of the etching machine. The material is selected as 316L stainless steel and PTFE composite material in compliance with SEMI F57 standard. The precipitation of metal ions is less than 0.1ppm, suitable for a Class 10 cleanroom environment, and has passed the IP67-level protection certification at the same time It can withstand a wide operating temperature range from -40 ℃ to 85℃ and a high humidity environment of 95% RH. The structural design adopts fanless sealed packaging to prevent the generation and accumulation of particles, meeting the strict requirements of clean processes such as thin film deposition.

Iv. Multi-level Security and Diagnostic Mechanism

Based on the high reliability requirements of semiconductor production lines, the module has built a full-chain intelligent protection system. At the hardware level, it integrates dual protection circuits for signal overvoltage and overcurrent. When an abnormal signal is detected, isolation protection can be triggered within 5μs to prevent damage to the precision circuits of the back-end equipment. The software level is equipped with a real-time self-checking function, capable of monitoring 16 types of faults such as interface loosening and matching circuit failure. It provides dual output warnings through dry contacts and network alarms, and automatically switches to redundant communication links to ensure the continuous operation of the production line. In addition, the module has passed the SEMI S2/S8 safety certification and supports hierarchical management of operation permissions. Unauthorized personnel cannot modify the matching parameters, reducing the risk of human error operation.

AMAT Applied Materials 0190-42550匹配网络模块 产品展示

产品视频

3.其他产品

Schneider 140CPS11100模拟输入模块

Schneider 140CPU43412A 控制器模块

CHBX01L 2VAA008574R1 总线扩展器

4.其他英文产品

SST-1500-YCX-3-1-0 Communication module

TEWS TPMC871-50 Interface module

Woodward EASYGEN-3500-5 P2 8440-2145 Speed controller

| SR469-P1-HI-A1-E-H | AMAT 0100-02195 | 5716075-K DSDX451 ABB |

| SR469-P1-HI-A1-E | AMAT 0100-90517 | PFEA 113-65.1PXV |

| SR3720-3798-7-56C | AMAT 0100-93404 | PFCL 201CD-20.0KN |

| SR3720-3798-2A-56C | AMAT 0110-20001 | 57160001-UH DSTD150A ABB |

| SR3662-8292-2-48B | AMAT 0100-02409 | PFCL 201CE-20.0KN |

| SR3658-2255-7-56B | AMAT 0100-00206 | PFEA111-IP20 3BSE050090R20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218