AMAT Applied Materials 0100-AE018系统主板

1.产 品 资 料 介 绍:

- 适用系统:优先适配 AMAT Endura/Centura 系列半导体设备,兼容 AMAT 同类晶圆处理设备的主控系统

- 核心配置:工业级四核处理器(主频 1.5GHz),板载 2GB DDR4 内存、16GB eMMC 存储(用于存储系统固件与工艺参数)

- 接口资源:4 路 EtherCAT 接口(实时控制模块,周期≤1ms)、2 路千兆以太网接口(MES 系统 / 上位机通信)、8 路 RS485 接口(连接传感器 / 执行器)、16 路数字量 I/O(24V DC,用于状态监测)、4 路 PCIe 插槽(扩展功能模块)

- 控制功能:支持多模块协同调度(运动控制、工艺参数调节并行处理)、故障诊断与日志存储(可存 1000 条故障记录)、工艺程序导入 / 导出(支持 USB / 以太网传输)

- 电源需求:DC 24V±10% 双路冗余输入,功耗≤30W(满负载运行),具备过压(30V)、欠压(18V)、过流(2A)保护

- 物理尺寸:长 300mm× 宽 220mm(标准 ATX 版型),安装孔位适配原厂设备主控柜,M3 螺丝固定(力矩 0.6-0.8N・m)

- 环境适应:工作温度 0℃-60℃,相对湿度≤85% RH(无凝露),抗电磁干扰符合 EN 61000-6-4 标准,PCB 板阻燃等级 UL94 V-0

- 高集成主控能力:四核处理器 + 多接口集成,可同时调度 8 + 功能模块,指令响应延迟≤500μs,满足设备多工序同步运行需求

- 原厂深度兼容:接口定义、固件协议、模块通信逻辑与原厂完全一致,替换后无需重新烧录系统固件,仅需加载原工艺参数即可恢复运行,停机更换时间≤2 小时

- 高可靠冗余设计:双路电源冗余输入(单路故障自动切换)、关键芯片防静电保护(ESD 等级 ±15kV),平均无故障运行时间(MTBF)≥8 万小时,适应半导体设备长期连续生产

AMAT Applied Materials 0100-AE018系统主板 英文资料:

1、 Product Overview

The AMAT 0100-AE018 system motherboard is the main control center of semiconductor wafer processing equipment, such as the AMAT Endura series PVD coating machine and Centura series etching machine. It is mainly responsible for signal aggregation, instruction distribution, and collaborative scheduling of various functional modules (driver modules, sensors, process control units) of the equipment. At the same time, it realizes data exchange with the upper computer and factory MES system, and is the core carrier of the full process automation operation of the equipment. The motherboard adopts a highly integrated circuit design and anti-interference layout, which can directly replace the original motherboard of the same model without the need to reconstruct the device control logic, and quickly restore the main control function of the device.

2、 Key parameters

Applicable system: Priority adaptation to AMAT Endura/Century series semiconductor equipment, compatible with the main control system of similar AMAT wafer processing equipment

Core configuration: Industrial grade quad core processor (with a clock speed of 1.5GHz), onboard 2GB DDR4 memory, 16GB eMMC storage (for storing system firmware and process parameters)

Interface resources: 4 EtherCAT interfaces (real-time control module, cycle ≤ 1ms), 2 Gigabit Ethernet interfaces (MES system/upper computer communication), 8 RS485 interfaces (connecting sensors/actuators), 16 digital I/O (24V DC, used for status monitoring), 4 PCIe slots (expansion function module)

Control function: Supports multi module collaborative scheduling (motion control, parallel processing of process parameter adjustment), fault diagnosis and log storage (can store 1000 fault records), process program import/export (supports USB/Ethernet transmission)

Power requirement: DC 24V ± 10% dual redundant input, power consumption ≤ 30W (full load operation), with overvoltage (30V), undervoltage (18V), and overcurrent (2A) protection

Physical dimensions: 300mm in length and 220mm in width (standard ATX version), with installation holes suitable for the original equipment main control cabinet, fixed with M3 screws (torque 0.6-0.8N · m)

Environmental adaptation: Working temperature of 0 ℃ -60 ℃, relative humidity ≤ 85% RH (no condensation), anti electromagnetic interference in accordance with EN 61000-6-4 standard, PCB board flame retardant grade UL94 V-0

3、 Core advantages

High integration control capability: quad core processor+multi interface integration, capable of scheduling 8+functional modules simultaneously, instruction response delay ≤ 500 μ s, meeting the requirements of synchronous operation of multiple processes in equipment

Original factory deep compatibility: The interface definition, firmware protocol, and module communication logic are completely identical to those of the original factory. After replacement, there is no need to re burn the system firmware, only the original process parameters need to be loaded to resume operation. The downtime for replacement is ≤ 2 hours

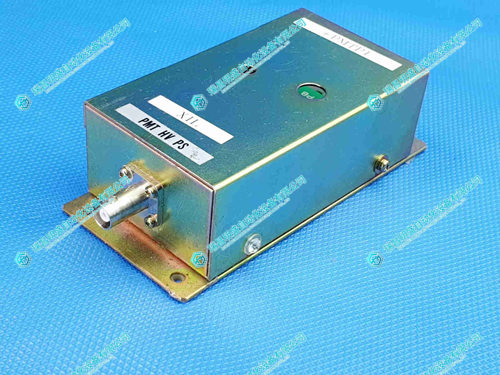

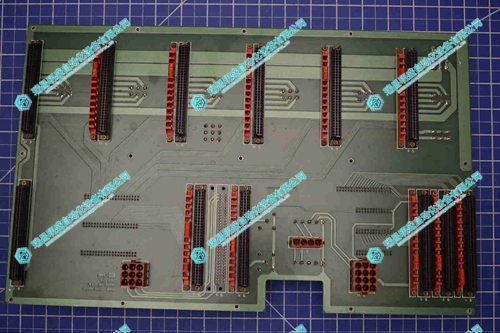

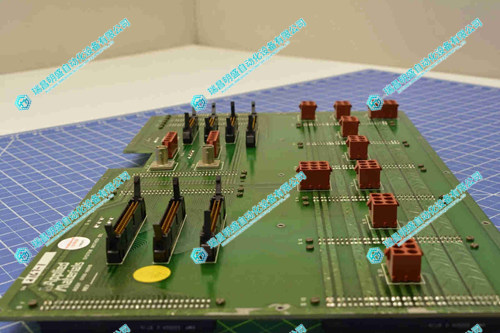

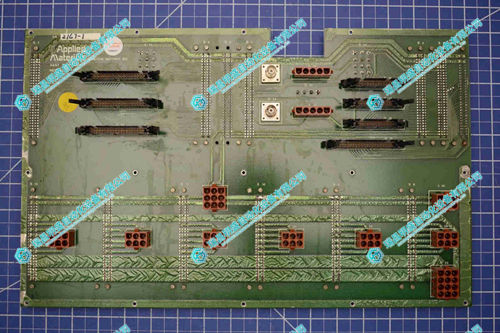

AMAT Applied Materials 0100-AE018系统主板 产品展示

产品视频

3.其他产品

Rexroth DKCXX.3-040-7生态驱动器

Kollmorgen PRD-B040EAIB-33 CE03550伺服驱动器

VIBRO-METER MPC4 200-510-078-115机械保护卡

4.其他英文产品

TRICONEX IMSS 4701X Input module

BACHMANN SFS236C connector module

COOPER P3798102-00010 CN-UIM2 Operation panel

| AMAT 0190-09468 | AMAT 0190-36065 | AMAT 0190-13127 |

| AMAT 0020-39499 | AMAT 0190-36093 | AMAT 0190-13128 |

| AMAT 0190-14374 | AMAT 0190-36109 | AMAT 0190-13129 |

| AMAT 0190-34282 | AMAT 0190-36181 | AMAT 0190-13139 |

| AMAT 0190-28262 | AMAT 0190-36184 | AMAT 0190-13175 |

| AMAT 0190-20096 | AMAT 0190-36252 | AMAT 0190-13206 |

| AMAT 0190-76276 | AMAT 0190-36253 | AMAT 0190-13213 |

| AMAT 0190-12032 | AMAT 0190-36320 | AMAT 0190-13214 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218