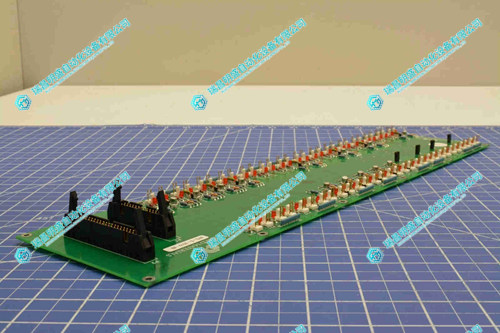

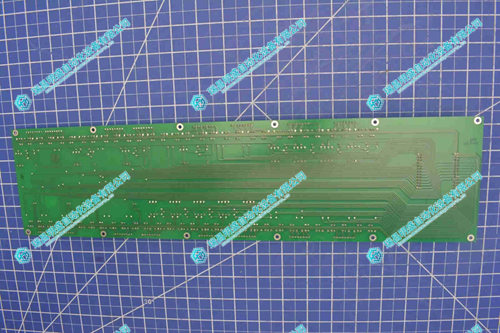

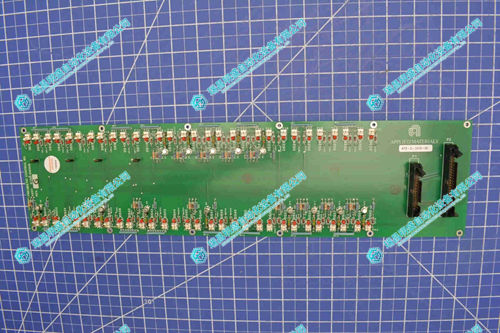

AMAT Applied Materials 0100-09008气动控制板

1.产 品 资 料 介 绍:

- 多通路精准气动调控

- 高效信号处理与协同能力

- 自适应负载调节功能

- 全链路故障防护机制

- 实时状态监测与通讯

- 抗干扰与隔离设计

AMAT Applied Materials 0100-09008气动控制板 英文资料:

1、 Core Control Performance Characteristics

Multi channel precise pneumatic control

Specially designed for pneumatic systems, it can simultaneously control multiple valves (presumably supporting 8-16 independent channels), and accurately adjust the pressure, flow rate, and flow direction of compressed air through digital signals. Using pulse width modulation (PWM) technology and closed-loop feedback control, the valve response time is ≤ 10ms, and the pressure regulation accuracy reaches ± 0.01MPa, which can meet the micro level action control requirements of components such as wafer transfer robotic arms and vacuum chucks.

Efficient signal processing and collaborative capabilities

Equipped with an industrial grade microcontroller (presumably ARM Cortex-M series), it has high-speed instruction execution capability, can analyze control signals from the device main control unit in real time, and synchronously output valve drive instructions. Support seamless linkage with the 0190-24007 single board computer to achieve the coordinated operation of pneumatic actuators and electrical control systems, ensuring the continuity of processes such as wafer handling and process chamber switching.

Adaptive load regulation function

Built in load detection algorithm that can automatically adjust output parameters based on the operating status of pneumatic actuators such as cylinders and grippers. When there is a sudden change in load (such as when a robotic arm grabs a wafer), it can instantly compensate for air pressure and flow rate, avoid motion lag or positioning deviation, and adapt to the dynamic operation requirements of semiconductor equipment under multiple working conditions.

2、 Security protection and monitoring characteristics

Full link fault protection mechanism

Integrated multiple safety protection functions, including overvoltage protection (automatic cut-off of gas source for pneumatic system pressure ≥ 1.2MPa), overcurrent protection (triggering power outage when driving circuit current exceeds the limit), disconnection detection (instant alarm for valve control line disconnection), and timeout protection (error message within 10 seconds of incomplete action). The fault response time is less than 5ms, which can quickly cut off the dangerous path and lock the output to prevent mechanical collision or wafer damage.

Real time status monitoring and communication

Equipped with RS485/Modbus communication interface, it supports real-time uploading of 12 key parameters such as valve switch status, pipeline pressure, and board temperature to MES system. By integrating LED indicator lights and fault code output functions, operation and maintenance personnel can quickly locate problems (such as valve sticking or abnormal pressure) through the equipment panel or backend system, shortening the troubleshooting time.

Anti interference and isolation design

By using optoelectronic isolation technology (isolation voltage ≥ 2500V DC), the control circuit is physically isolated from the drive circuit, effectively resisting electromagnetic interference generated by RF equipment and motors. The onboard EMC filtering circuit complies with the EN 55022 Class B electromagnetic compatibility standard, avoiding signal interference to sensitive electronic components in the surrounding area.

AMAT Applied Materials 0100-09008气动控制板 产品展示

产品视频

3.其他产品

EATON APR24-3G整流器模块

AKT 0100-71443通信接口

Pepperl+Fuchs KFU8-DWB-1.D电压保护器

4.其他英文产品

ALSTOM IR139-1 Control card

ALSTOM LC105A-1 Power protection module

CB801 3BSE042245R1 Terminal module

| AMAT 0100-01587 | AMAT 0190-40072 | AMAT 0190-14442 |

| AMAT 0100-01984 | AMAT 0190-40076 | AMAT 0190-14450 |

| AMAT 0100-A1251 | AMAT 0190-40086 | AMAT 0190-14478 |

| AMAT 0100-A2540 | AMAT 0190-40092 | AMAT 0190-14479 |

| AMAT 0100-76018 | AMAT 0190-40096 | AMAT 0190-14713 |

| AMAT 0100-71056 | AMAT 0190-40109 | AMAT 0190-14750 |

| AMAT 0100-01691 | AMAT 0190-40129 | AMAT 0190-14752 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218