GIDINGS&LEWIS 572-03638-61 可编程工业计算机

1.产 品 资 料 介 绍:

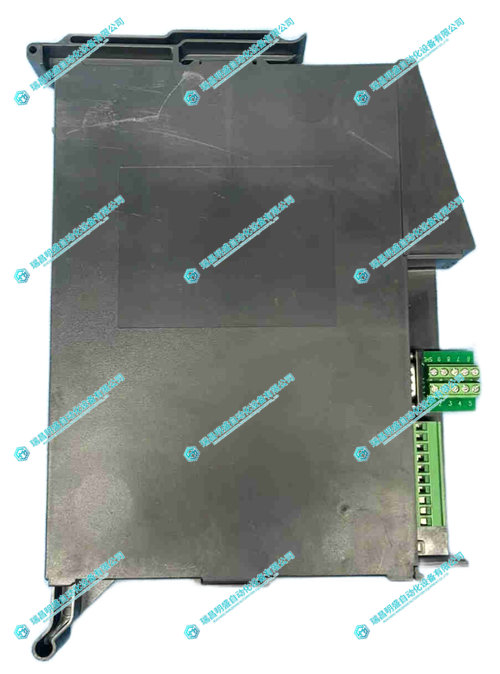

GIDDINGS & LEWIS 572-03638-61 可编程工业计算机解析

一、产品概述

二、技术参数(典型特性)

英文资料:

GIDINGS&LEWIS 572-03638-61 Programmable Industrial Computer Analysis

1、 Product Overview

GIDINGS&LEWIS 572-03638-61 programmable industrial computer is a high-performance computing core specifically designed for industrial automation and control systems. It takes "receive process execute" as its core logic, which can accurately receive program instructions from the upper control system, complete instruction parsing and logical operations through the built-in high-speed processing unit, and then convert the operation results into executable signals to achieve automated control of industrial machinery equipment actions and production process rhythms. This industrial computer combines programmable flexibility, modular expansion advantages, and industrial grade high reliability. It can adapt to multi axis collaborative control of complex CNC machine tools, meet the global scheduling needs of automated production lines, and is compatible with other industrial control scenarios. It has become a key unit in industrial automation systems that combines "computing power" and "control power".

2、 Technical parameters (typical characteristics)

Product model: 572-03638-61

Functional positioning: A programmable industrial computer that integrates computing and control, with core capabilities of industrial controllers, suitable for multi scenario automation needs

Processing capability: Equipped with a high-speed industrial grade processor, with high computing frequency and large data processing bandwidth, it can smoothly run complex control programs (such as multi axis linkage control algorithms and batch production scheduling logic), support multi task parallel execution, and avoid control delays caused by program lag

Storage and Expansion: Equipped with sufficient built-in cache and local storage (for storing basic control programs and system configuration files), as well as expandable storage module interfaces (such as SD cards and industrial hard disk slots), it facilitates users to store massive production data, historical operation logs, and custom control programs. The storage capacity can be upgraded as needed

Input/output interface: equipped with multi-channel digital I/O (for switch signal interaction, such as device start stop and fault alarm) and analog I/O (for continuous signal acquisition and output, such as temperature and pressure sensor signal reception, actuator adjustment signal output), interface specifications are compatible with mainstream sensors and actuators on the market, without the need for additional adaptation conversion modules

Communication capability: Supports multiple industrial bus protocols (such as Profibus, Modbus) and serial communication interfaces (such as RS232, RS485), and can achieve high-speed data exchange with upper management computers, PLCs (programmable logic controllers), and CNC systems. It can receive scheduling instructions from upper systems and upload equipment operation data, achieving interconnection and intercommunication of industrial control networks

2.产 品 展 示

3.其他产品

KOLLMORGEN CP310250 PRD-P310250Z-55 伺服驱动器

4.其他英文产品

ABB XVC768117 Field Input/Output Module

Eaton XV-440-10TVB-1-50 Touch Screen

FOXBORO FBM217 Voltage Monitor Module

| IC3600LMIA1 | 531X170TBSAFG1 | IC3600AVIA1J |

| IC3600LLXA1A | 531X170TBSAEG1 | IC3600AVIA1D |

| IC3600LLXA1 | 531X170TBSADS1 | IC3600AVIA1C |

| IC3600LLRC1 | 531X170TBSADG1 | IC3600AVIA1B |

| IC3600LLEB1 | 531X170TBSACG1 | IC3600AVIA1 |

| IC3600LLEA1B | 531X170TBSABG1 | IC3600ASOB1A |

| IC3600LLEA1 | 531X170TBSAAG1 | IC3600ARMB1C |

Contact: +86 15270269218