GIDINGS&LEWIS M.1300.9602处理器

1.产 品 资 料 介 绍:

Giddings & Lewis M.1300.9602 核心处理器模块介绍

一、产品概述

二、产品特点

(一)高性能处理能力

(二)模块化设计

英文资料:

Introduction to Giddings&Lewis M.1300.9602 Core Processor Module

1、 Product Overview

The Giddings&Lewis M.1300.9602 core processor module is the "nerve center" and "decision core" of PiC series control systems, directly determining the operational performance, control accuracy, and stability of CNC machine tools and automation equipment. Its core responsibilities cover three dimensions: firstly, executing control programs written by users, converting preset processing logic and equipment action instructions into specific control signals; The second is to efficiently process logical operations (such as equipment start stop interlocking, fault diagnosis) and motion control instructions (such as multi axis linkage, precise positioning) to ensure that equipment actions meet process requirements; The third is to comprehensively manage the input and output (I/O) signals of the system, coordinate the data exchange of sensors, actuators, servo drives and other peripherals, and form a complete control loop.

In the field of industrial automation, whether it is high-precision machining of CNC machine tools or complex motion control of multi axis equipment, this module can provide powerful computing and scheduling capabilities, and is the core component to ensure efficient and stable operation of industrial equipment.

2、 Product Features

(1) High performance processing capability

Industrial grade CPU support: Module integration is a high-performance CPU designed specifically for industrial scenarios, with excellent computing speed and data processing capabilities. In terms of logical operations, it can quickly parse complex control logic (such as multi condition interlock protection, production process judgment), ensuring that the equipment responds to external signals within milliseconds; In multi task parallel processing, multiple tasks such as motion control, I/O signal management, and data acquisition can be scheduled simultaneously. For example, in the CNC machining process, tool position calculation, spindle speed adjustment, and machining progress monitoring can be synchronously processed to avoid response delays caused by task queues and greatly improve the overall operating efficiency of the system.

Complex task adaptation: With powerful computing power, it can easily handle complex motion control tasks (such as multi axis interpolation, synchronous motion) and process logic (such as variable machining parameter adjustment, batch production process control). For example, in mold processing scenarios, continuous motion commands need to be generated based on complex surface contours. The module can quickly complete trajectory planning and interpolation operations to ensure smooth and accurate tool motion; In automated production lines, the process logic of multi station collaboration can be handled, such as dynamically adjusting the assembly parameters of the next station based on the product inspection results of the previous station, to meet flexible production needs.

(2) Modular design

Convenient installation and adaptation: Adopting a plug-in module structure, the design size and interface specifications are fully compatible with the PiC series control system rack. During installation, the staff only need to align the module with the rack slot and gently insert it to complete mechanical fixation and electrical connection, without the need for complex wiring debugging, greatly reducing equipment assembly time; At the same time, standardized interface design ensures stable and reliable connections between modules and racks, avoiding contact failures caused by improper installation.

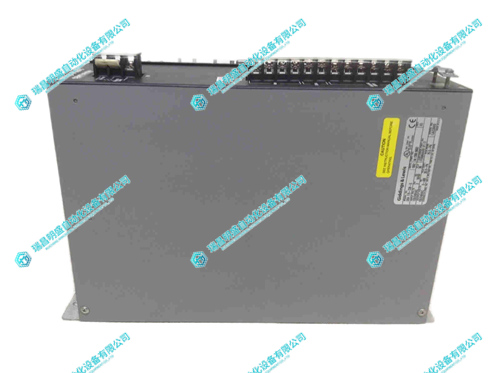

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA 57360001-AN circuit board

LAM 810-800081-016 CPU motherb

Siemens 6ES7291-8GC00-0XA0 cartridge

| SR3632-4336-7-48C | 531X306LCCBEM2 | IC3600TPCD1A |

| SR3632-382-2-48B | AMAT 0100-90697 | IC3600TPAM1 |

| SR3632-2094-48B | AMAT 0100-00039 | 26390582-BM DSTK129 ABB |

| SR3624-8291-7-56BC-CU-250210 | AMAT 0100-00736 | 57520001-A DSTC120 ABB |

| SR3624-8291-7-56BC-CU | AMAT 0100-00669 | PFEA 113-65.2PXC |

| SR3624-8291-48B | AMAT 0100-02134 | PFEA 112, IP 65 |

| SR3624-4991 | AMAT 0100-02888 | PFEA 113, IP 20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218