GIDINGS&LEWIS 502-03431-10机器接口板

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

The GIDDINGS&LEWIS 502-03431-10 machine interface board is an extremely critical component in industrial automation systems, like a bridge that builds stable and efficient connection channels between various industrial equipment and control systems. In complex and diverse industrial production environments, from large-scale automated production lines, to precision operated CNC machine tools, and to flexible collaborative industrial robots, this interface board plays an indispensable role in realizing signal interaction, data transmission, and instruction execution between equipment and control systems, helping the entire industrial production process achieve seamless integration and precise control, laying a solid foundation for efficient and stable operation of industrial production.

Core functional characteristics

Multi signal interaction: With powerful signal processing and interaction capabilities, it can simultaneously access multiple types of signals. On the one hand, it can accurately receive analog and digital signals from various sensors, such as analog temperature signals output by temperature sensors, digital position signals feedback by position sensors, etc., and adjust and convert these signals to meet the interface requirements of the control system, smoothly transmit them to the control system, and provide real-time and accurate data support for system decision-making. On the other hand, it can efficiently transmit control command signals issued by the control system, such as motor start stop commands, equipment operating parameter adjustment commands, etc., to the corresponding executing equipment, ensuring that the equipment accurately responds to control commands and achieves automated control of the production process.

Device Connection Adaptation: With a wide variety of interface types, it can easily adapt to the connection needs of different industrial devices. Equipped with multiple digital input and output interfaces, it can be directly connected to digital devices such as switches and relays to achieve monitoring and control of device status. At the same time, it has analog input and output interfaces, which can perfectly interface with various analog sensors and actuators, meeting the needs of analog signal processing in industrial production. In addition, it also supports serial communication interfaces (such as RS-485, RS-232) and fieldbus interfaces (such as CANopen, Modbus), which facilitate data communication and collaborative work with other intelligent devices and controllers, greatly improving the integration of the system and the flexibility of device connection.

Stable data transmission: Advanced circuit design and signal transmission technology are adopted to ensure the stability and accuracy of data during transmission. In industrial production sites, there are numerous sources of electromagnetic interference, such as the operation of large motors and the operation of high-frequency equipment, which can easily affect the quality of data transmission. The 502-03431-10 machine interface board effectively suppresses the influence of external interference signals on data transmission through good electromagnetic shielding design, filtering circuit, and anti-interference algorithm, ensuring the integrity and accuracy of signals, avoiding equipment misoperation or production accidents caused by data transmission errors, and providing strong guarantee for the reliable operation of industrial production.

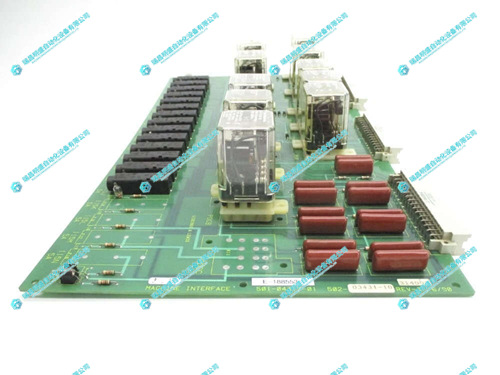

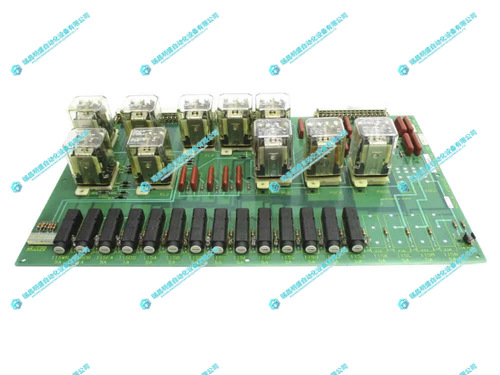

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA DSQC108 controller backplane

FOXBORO RH926GH Control Input Card

Fanuc A06B-6115-H006 servo drive

| 850-EP5NNS5HNNAANGAPCCSENNBN | AMAT 0100-90243 | PFEA 112, IP 20 |

| 850-EP5NNS5HNNAANGAPCB2ESNBN | AMAT 0100-76290 | 21660559-H DSRA110 ABB |

| 850-EP5NNS5HNNAAFGAPFB3ECNAN | AMAT 0100-11025 | PFCL201CD/CE |

| 850-EP5NNS1HNNAAAGMSFB1ECNBN | CACR-SR1B-E | 57360001-DC DSMC120 ABB |

| 850-EP5NNG5HNNANNGSSFBSEWNBN | CACR-SR03BE12M-E | 5735099-BA DSIH71 ABB |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218