GIDINGS&LEWIS 503-14814-00执行控制板

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

The GIDDINGS&LEWIS 503-14814-00 execution control board is a core hub component in industrial automation systems, responsible for key duties such as instruction reception, processing, and equipment execution control in complex industrial production systems. It is like the "smart brain" of industrial equipment, accurately coordinating the operation of various actuators, widely used in fields such as CNC machine tools, automated production lines, and industrial robots. With excellent performance and stable performance, it lays a solid foundation for the efficient, precise, and reliable operation of industrial production, and effectively promotes the process of industrial automation.

Core functional characteristics

Multi instruction processing: With powerful instruction parsing and processing capabilities, it can quickly and accurately receive various complex instructions issued by upper control systems such as programmable logic controllers (PLCs), industrial computers, etc. Whether it is a simple device start stop command or a combination command involving multi axis linkage and complex process actions, the 503-14814-00 execution control board can efficiently parse and convert it into corresponding control signals, ensuring that the actuator executes tasks accurately and without errors. In automated production lines, it is possible to quickly process and execute instructions such as material handling and process switching based on different stages of the production process, ensuring a tight and efficient production rhythm.

Multi device collaborative control: With multiple control output channels, it can simultaneously connect and control multiple types of actuators, achieving collaborative operation between multiple devices. It can drive equipment with different power sources such as motors, pneumatic actuators, hydraulic actuators, etc., and accurately coordinate the action sequence, speed, and force of each equipment according to production process requirements. In the automated assembly line of automotive parts manufacturing, the control board can synchronously control the grasping action of the robotic arm, the tightening force of the screw tightening machine, and the start stop and speed of the conveyor belt, so that all equipment can work closely together, efficiently complete the assembly work of parts, and greatly improve production efficiency and assembly accuracy.

Closed loop feedback control: supports the construction of a closed-loop control system with various sensors, by collecting real-time signals such as position, speed, pressure feedback from sensors, and comparing and analyzing them with preset target values. Once deviations are detected, quickly adjust the control strategy and precisely adjust the operating parameters of the actuator to ensure that the equipment always operates in a high-precision state. In the machining process of CNC machine tools, with the help of tool position information feedback from position sensors, the control board adjusts the operating parameters of the motor in real time, achieving micrometer level precision control of tool position, ensuring the machining accuracy of parts, and meeting the strict requirements of precision manufacturing for machining accuracy.

Signal compatibility and conversion: With a rich variety of interface types, it has good compatibility and conversion capabilities for digital, analog, and various feedback signals. Its digital input/output interface can be directly connected to digital devices such as switches and relays to achieve monitoring and control of device status; The analog interface can accurately adapt to various analog sensors and actuators, and complete the acquisition and output control of analog signals.

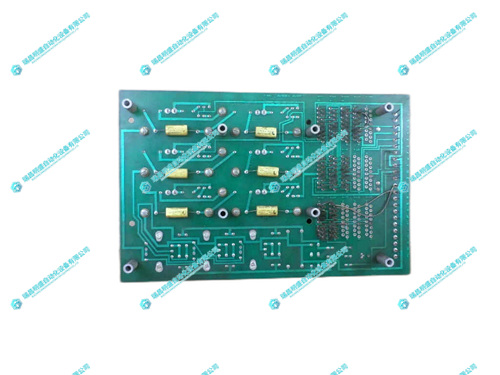

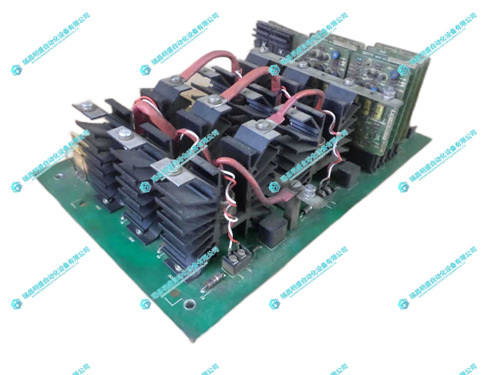

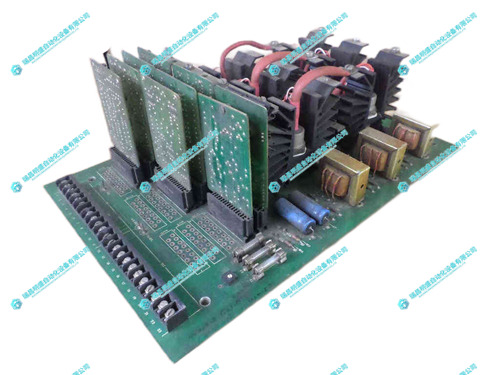

2.产 品 展 示

3.其他产品

4.其他英文产品

Fanuc A06B-6115-H006 servo drive

NI PCI4451 Data Acquisition Card

Emerson P144.R4 Intelligent I/O Board

| 850-EP5NNG5HNNALFGAPCASENNBN | AMAT 0100-00438 | MPCBL0001F04 |

| 850-EP5NNG5HNNALAGASFCSENWBN2 | AMAT 0100-98072 | SN32HMYW-LNK-NS-00 |

| 850-EP5NNG5HNNALAGAPFBSENNBN | AMAT 0100-91087 | 48797303 |

| 850-EP5NNG5HNNAANMASFB1ECNAN | AMAT 0100-94078 | 135837-008 |

| 850-EP5NNG5HNNAANGMPHB3ACNBN | AMAT 0100-09110 | 48011401 |

| 850-EP5NNG5HNNAANGAPFCSENNBN | AMAT 0100-76029 | EPC-5-66 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218