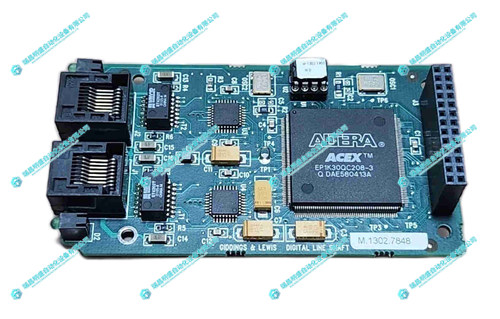

GIDINGS&LEWIS M.1302.7848数字线轴模块

1.产 品 资 料 介 绍:

产品概述

核心功能特性

英文资料:

Product Overview

GIDINGS&LEWIS M.1302.7848 digital spool module is a crucial component in the field of industrial automation, mainly used in various equipment with precise control requirements for wire processing. It is like the "intelligent center" of a device, precisely regulating the operation of wire transportation, winding, and release. It plays a key role in industries such as wire and cable manufacturing, textiles, and electronic equipment production, ensuring efficient and stable utilization of wire during the production process and providing strong support for improving product quality and production efficiency.

Core functional characteristics

Precise wire control: This module can accurately control the speed, tension, and position of the wire. In the production process of wires and cables, the speed of the spool can be accurately adjusted according to different production process requirements to ensure that the wire is transported at a constant speed and avoid uneven thickness of the cable caused by speed fluctuations. At the same time, through the built-in tension adjustment system, the tension of the wire is monitored and adjusted in real time to prevent the wire from becoming too loose and winding, or too tight and causing breakage, ensuring the stability of product quality.

Multi mode operation: supports multiple operation modes to adapt to different production scenarios. In continuous production mode, it can operate stably for a long time and continuously provide accurate wire supply for the production line; In intermittent production mode, it can quickly respond to start stop instructions and adjust the status of the spool when the equipment needs to be paused or restarted, ensuring flexible control of the production rhythm. For example, in the textile industry, flexible switching of operating modes can be achieved according to different stages of fabric weaving to achieve efficient production.

Data interaction and feedback: With strong data interaction capabilities, it can communicate in real-time with the upper control system. Receive production parameter instructions from the control system, such as line speed, winding number, etc., and provide feedback on the actual operating status of the spool, including speed, tension, and length of the conveyed wire, to the control system. Through this real-time data exchange, the entire production process can be automated and monitored accurately, making it easy to detect and solve production problems in a timely manner.

Device compatibility: It has good compatibility and can be integrated with various brands and models of production equipment. Whether it's wire and cable manufacturing equipment, textile machinery, or electronic equipment manufacturing production lines, they can all be easily adapted. Its rich interface types, such as digital input/output interfaces, analog interfaces, and commonly used communication interfaces (such as RS-485, Modbus, etc.), facilitate connection and communication with different devices, greatly improving the flexibility and convenience of device integration.

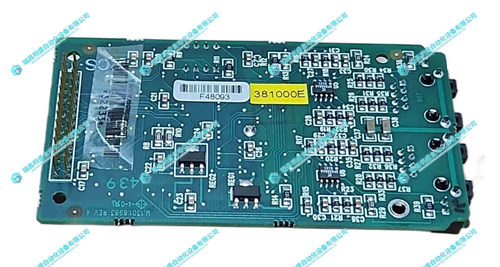

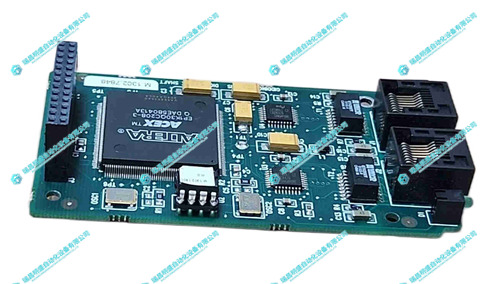

2.产 品 展 示

3.其他产品

4.其他英文产品

Emerson P144.R4 Intelligent I/O Board

ABB XVC768117 Field Input/Output Module

Eaton XV-440-10TVB-1-50 Touch Screen

| 845-EP5H5G5HNNAANGSSFB2ESNBN | AMAT 0100-71320 | 710-615443-001 |

| 845-EP5H5G5HNNAANGSPFBSENNBN | AMAT 0100-AE018 | 780-10727-002 |

| 845-EP5H5G5HNNAANGASFB2ESNBN | AMAT 0100-01339 | ICS TRIPLEX R65C52P2 |

| 820-23550-000 | AMAT 0100-09213 | EXM-13A |

| 820-23514-000 | AMAT 0100-09307 | 8MA01 |

| 820-22112-00 | AMAT 0100-02292 | 6ES5420-4UA14 |

| 820-22111-000 | CACR-SR12TZ0SMY01A | 6ES54201BA11 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218