1.产 品 资 料 介 绍:

853-286086-100多频控制器相关说明

1. 853-286086-100为工业级多频控制器,适配电阻焊高精度焊接控制场景

2. 支持多频段切换,涵盖中频、高频脉冲等模式,适配多材质焊接需求

3. 具备精准热输入控制,可减少焊接飞溅,适配薄板、镀层材料焊接

4. 工作温度范围-10℃至55℃,适配常规工业车间焊接环境

5. 支持预热、主焊、回火多段焊接模式,降低焊接应力

6. 内置负载特性智能识别,可自动推荐最优频率与能量输出模式

7. 配备Modbus、EtherCAT等通讯接口,可与PLC、机器人无缝对接

8. 支持焊接参数实时监控,异常时自动调整或停机保护

9. 存储多组工艺参数模板,可快速切换适配不同批次生产需求

10. 高频逆变模块设计,电能转换效率高,能耗低更节能环保

11. 板载多状态指示灯,实时反馈运行、通讯及焊接异常状态

12. 模块化结构设计,安装维护便捷,适配自动化产线布局

13. 需专业人员安装调试,严格遵循焊接工艺参数配置规范

14. 焊接作业区严禁吸烟,需配备灭火器材,做好防火防爆措施

15. 出厂经电气性能、焊接精度等全流程检测,符合工业质量标准

853-286086-100多频控制器 英文资料:

853-286086-100 Multi frequency Controller Description

853-286086-100 is an industrial grade multi frequency controller suitable for high-precision welding control scenarios in resistance welding

2. Supports multi band switching, covering modes such as mid frequency and high-frequency pulses, and adapts to the welding needs of multiple materials

3. With precise heat input control, it can reduce welding spatter and adapt to welding of thin plates and coating materials

4. Working temperature range -10 ℃ to 55 ℃, suitable for conventional industrial workshop welding environment

5. Support preheating, main welding, and tempering multi-stage welding modes to reduce welding stress

6. Equipped with intelligent recognition of load characteristics, it can automatically recommend the optimal frequency and energy output mode

7. Equipped with communication interfaces such as Modbus and EtherCAT, it can seamlessly integrate with PLCs and robots

8. Support real-time monitoring of welding parameters, automatic adjustment or shutdown protection in case of abnormalities

9. Store multiple sets of process parameter templates, which can quickly switch and adapt to different batch production needs

10. High frequency inverter module design, high energy conversion efficiency, low energy consumption, more energy-efficient and environmentally friendly

11. Onboard multi state indicator light, providing real-time feedback on abnormal operation, communication, and welding status

12. Modular structure design, easy installation and maintenance, suitable for automated production line layout

13. Professional personnel are required for installation and debugging, strictly following the welding process parameter configuration specifications

14. Smoking is strictly prohibited in the welding operation area, fire extinguishing equipment must be equipped, and fire and explosion prevention measures must be taken

15. The factory has undergone full process testing for electrical performance, welding accuracy, etc., and meets industrial quality standards

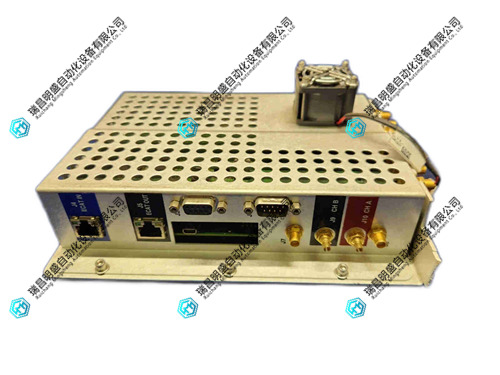

853-286086-100多频控制器 产品展示

产品视频

3.其他产品

Honeuwell 05701-A-0325控制模块

ICS TRIPLEX T9110控制模块

honeywell 05704-A-0144气体控制卡

4.其他英文产品

EPRO PR9268/307-100 9200-06121n front-end

PHILIPS SCM040 940860010011 Digital output module

SD-108542 processor

| OCE940-001-01 | AMAT 0100-02734 | NKTU01-15 |

| OC950-604-01 | AMAT 0100-00455 | 57310001-KH DSBC173 ABB |

| OC950-603-01 | AMAT 0100-20068 | DSBB175 ABB |

| OC950-602-01 | AMAT 0100-09031 | NKST01-10 |

| OC950-601-01 | AMAT 0100-20032 | HESG447308R0001 70EA02A-ES |

| OC950-504-01 | AMAT 0100-00720 | HESG446457R0001 70ER01A |

| OC950-503-01 | AMAT 0100-90704 | NKTU01-10 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218