1.产 品 资 料 介 绍:

20704A-26429真空排气监视器 产品概述及应用领域

20704A-26429真空排气监视器是真空系统排气过程中的核心监测设备,具备高精度真空度采集、实时排气状态监控及异常报警功能,支持多通道参数检测与数据记录追溯。其采用抗干扰传感设计与稳定的通讯模块,可适配从低真空到超高真空的多工况排气监测需求,能实时反馈排气系统运行参数并联动控制系统实现故障预警,为真空工艺的稳定性与安全性提供保障,广泛应用于对真空排气质量有严苛要求的工业制造、科研实验等领域,核心应用如下:

一、半导体与电子制造领域

核心场景:适配半导体晶圆制造过程中的真空排气系统,实时监测刻蚀、薄膜沉积等工艺腔室的排气真空度与气体流量参数,确保排气过程稳定以避免杂质残留影响芯片良率;应用于红外探测器杜瓦真空排气台,同步采集排气过程中的真空度、温度等关键数据,通过通讯模块上传至数据系统实现全流程记录追溯;支撑电子元件封装的真空排气工艺监测,及时发现排气异常并触发报警,保障封装密封性。

二、光伏能源领域

核心场景:应用于太阳能电池片制造的PECVD设备排气系统,精准监测镀膜腔室排气过程中的真空度变化,保障反应气体充分排出以提升薄膜沉积质量;适配单晶炉、多晶硅铸锭炉的真空排气环节,实时监控炉内排气真空度,避免空气混入影响晶体纯度;支撑光伏组件层压工艺的排气监测,确保腔室内空气与水分完全排出,防止组件内部产生气泡缺陷。

三、医疗与科研实验领域

核心场景:适配粒子治疗系统的真空束流通道排气监测,实时反馈真空度状态,及时发现排气异常以避免系统宕机,保障粒子束流传输稳定性;应用于生物安全柜的真空排气系统,监测柜内负压排气状态,防止有害微生物或气体泄漏,保障实验环境安全;作为科研实验设备的配套监测组件,用于真空烤箱、电子束蒸发装置等设备的排气过程监测,提供精准参数数据支撑实验研究。

四、通用工业制造领域

核心场景:适配化工行业真空反应釜的排气系统,监测排气过程中的真空度与腐蚀性气体排出状态,保障反应安全与环境友好;应用于真空镀膜设备(如光学镜片、装饰镀膜)的排气环节,实时调控排气速率以维持稳定真空环境,提升镀膜层均匀性;支撑冶金行业真空冶炼设备的排气监测,确保炉内杂质气体充分排出,提升金属材料纯度。

20704A-26429真空排气监视器 英文资料:

20704A-26429 Vacuum Exhaust Monitor Product Overview and Application Fields

The 20704A-26429 vacuum exhaust monitor is the core monitoring equipment in the vacuum system exhaust process, with high-precision vacuum degree acquisition, real-time exhaust status monitoring, and abnormal alarm functions, supporting multi-channel parameter detection and data recording traceability. It adopts anti-interference sensing design and stable communication module, which can adapt to multi working condition exhaust monitoring requirements from low vacuum to ultra-high vacuum. It can provide real-time feedback of exhaust system operating parameters and link with the control system to achieve fault warning, providing guarantees for the stability and safety of vacuum technology. It is widely used in industrial manufacturing, scientific research experiments and other fields that have strict requirements for vacuum exhaust quality. The core applications are as follows:

1、 Semiconductor and Electronic Manufacturing Field

Core scenario: Adapt to the vacuum exhaust system in the semiconductor wafer manufacturing process, monitor the exhaust vacuum degree and gas flow parameters of process chambers such as etching and thin film deposition in real time, ensure stable exhaust process to avoid impurity residue affecting chip yield; Applied to the infrared detector Dewar vacuum exhaust station, it synchronously collects key data such as vacuum degree and temperature during the exhaust process, and uploads it to the data system through the communication module to achieve full process recording and traceability; Monitor the vacuum exhaust process supporting electronic component packaging, promptly detect exhaust abnormalities and trigger alarms to ensure packaging sealing.

2、 Photovoltaic energy field

Core scenario: Used in the exhaust system of PECVD equipment for solar cell manufacturing, accurately monitoring the changes in vacuum degree during the exhaust process of the coating chamber, ensuring sufficient discharge of reaction gases to improve the quality of thin film deposition; Adapt to the vacuum exhaust process of single crystal furnaces and polycrystalline silicon ingot furnaces, monitor the vacuum degree of exhaust in the furnace in real time, and avoid air mixing that affects crystal purity; Exhaust monitoring to support the lamination process of photovoltaic modules, ensuring complete removal of air and moisture from the chamber and preventing the formation of bubble defects inside the modules.

3、 Medical and scientific experimental fields

Core scenario: Vacuum beam channel exhaust monitoring adapted to particle therapy system, real-time feedback of vacuum degree status, timely detection of exhaust abnormalities to avoid system downtime, and ensuring the stability of particle beam transmission; The vacuum exhaust system applied to biosafety cabinets monitors the negative pressure exhaust status inside the cabinet, prevents harmful microorganisms or gas leakage, and ensures the safety of the experimental environment; As a supporting monitoring component for scientific research experimental equipment, it is used for monitoring the exhaust process of equipment such as vacuum ovens and electron beam evaporation devices, providing accurate parameter data to support experimental research.

4、 General industrial manufacturing field

Core scenario: Adapt to the exhaust system of vacuum reactors in the chemical industry, monitor the vacuum degree and corrosive gas discharge status during the exhaust process, and ensure reaction safety and environmental friendliness; Applied to the exhaust process of vacuum coating equipment (such as optical lenses and decorative coatings), the exhaust rate is adjusted in real time to maintain a stable vacuum environment and improve the uniformity of the coating layer; Support the exhaust monitoring of vacuum smelting equipment in the metallurgical industry to ensure the full discharge of impurity gases in the furnace and improve the purity of metal materials.

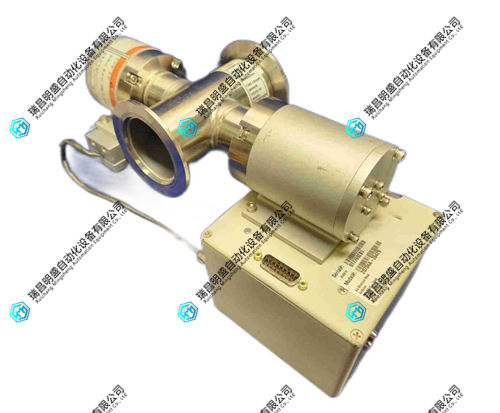

20704A-26429真空排气监视器 产品展示

产品视频

3.其他产品

Siemens 3VL9440-7DC30框架断路器

GE HE693RTD600工控自动化备件

GE HYDRAN M2单气体变压器

4.其他英文产品

FBMSSW output signal module

FLN4234A CPU3680 output signal card

PFEA111-20 3BSE028140R0020 controller

| F46HEAA-R2-NS-NV-00 | 531X132APGAAG1 | F31X300CCHADG1 |

| F46HCNA-R2-NS-NV-00 | 531X129SNCG1 | F31X300CCHAAG1 |

| F46GENA-R2-NS-NV-00 | 531X129SNCADG1 | F31X210DMCACG1 |

| F46GEBA-R4-NS-NV-00 | 531X128HMSAGG1 | F31X199SPTACG1 |

| F46GEAA-R2-NS-NV-00 | 531X128HMSADG2 | F31X191RTBAG3 |

| F46GCNA-R2-NS-NV-00 | 531X128HMSADG | F31X191RTBAFG3 |

| F45HENA-R2-NS-NV-00 | 531X128HMSACG2 | F31X191RTBAEG2 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218