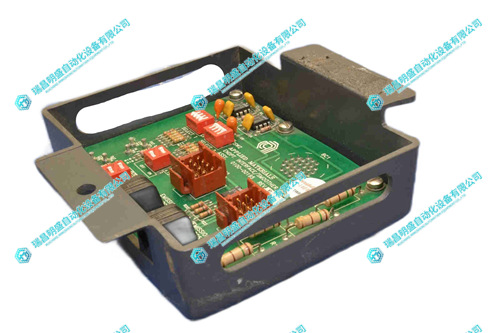

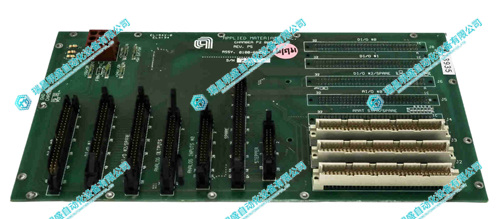

AMAT Applied Materials 0120-90622控制器

1.产 品 资 料 介 绍:

AMAT Applied Materials 0120-90622 控制器

一、核心规格与技术参数

二、典型应用场景

AMAT Applied Materials 0120-90622控制器 英文资料:

AMAT Applied Materials 0120-90622 Controller

AMAT 0120-90622 is an iSystem designed specifically for semiconductor wafer process equipment ® The intelligent factory system controller focuses on energy consumption monitoring, environmental data acquisition, and operation optimization of 200 mm/300 mm wafer equipment, while also possessing equipment status synchronization and safety control capabilities. It is a key component for achieving factory level energy management and process collaboration.

1、 Core specifications and technical parameters

Detailed description of project specifications/indicators

Functional positioning: energy consumption monitoring+data collection+optimization control. Real time collection of equipment parameters such as power consumption, gas consumption, temperature and humidity, etc., generating energy consumption and greenhouse gas emission analysis reports to assist in process energy-saving optimization

Applicable equipment: 200 mm/300 mm wafer process equipment compatible with AMAT's own etching, film deposition, cleaning and other equipment, while supporting third-party process tools that comply with industry standards

Device access quantity: A single controller with ≤ 4 tools can achieve synchronous monitoring of multiple devices at the Fab (wafer fab) or sub Fab level, reducing the number of hardware deployments

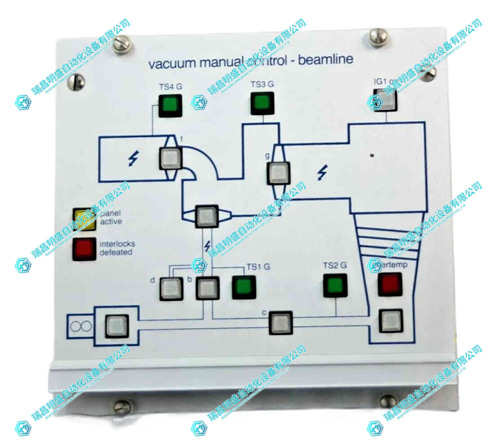

The fail safe mechanism in safety design automatically triggers the device safety protection mode when the controller or communication link is abnormal, avoiding process interruption or data loss, and ensuring production safety and data integrity

Intelligent Idle mode recognition device with energy-saving function can automatically adjust device operating parameters (such as reducing local power consumption and adjusting gas flow) during non production periods (such as standby and maintenance intervals), in compliance with SEMI E167 (device sleep mode) and SEMI E175 (energy management standards)

Data exchange supports the E3 standard, and the FSS data server can be connected to the factory level E3 (Equipment Engineering Data Collection) system or FSS (Factory Service System) data server to achieve the summary, analysis, and traceability of equipment data throughout the factory

Power supply and size standard industrial DC power supply (24 VDC ± 10%); Compact design suitable for installation space in most semiconductor equipment control cabinets, without the need for additional layout space, making it easy to integrate into existing systems

2、 Typical application scenarios

Semiconductor wafer manufacturing: used for core process tools such as etching machines, PECVD (plasma enhanced chemical vapor deposition) equipment, cleaning machines, etc., to monitor real-time energy consumption of single or multiple devices, optimize production scheduling to reduce overall energy consumption.

Flat panel display (LCD/OLED) process: Adapt to equipment such as evaporation and exposure in display panel manufacturing, collect energy consumption and environmental parameters during the process, and assist in improving process stability and energy utilization efficiency.

Photovoltaic cell production: For equipment such as photovoltaic silicon wafer coating and etching, high energy consumption links are identified through energy consumption data analysis, combined with intelligent idle mode to reduce energy waste during non production periods.

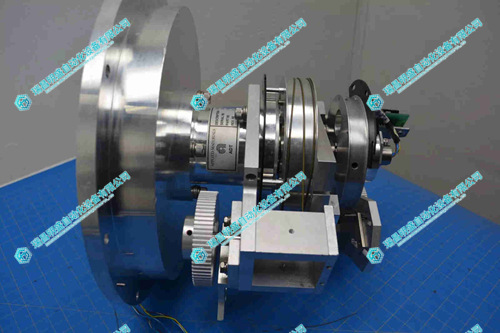

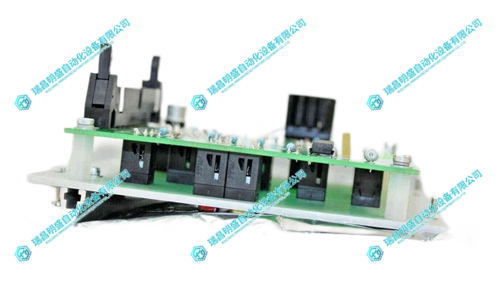

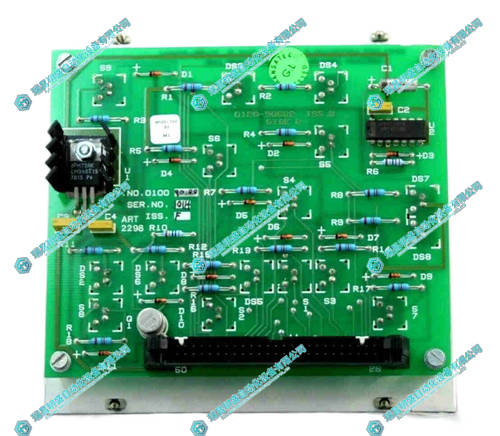

AMAT Applied Materials 0120-90622控制器 产品展示

产品视频

3.其他产品

Emerson 1C31181G02 输入/输出模块

WESTINGHOUSE 1C31179G02 遥控 I/O 模块

MITSUBISHI Q06HCPU逻辑控制器

4.其他英文产品

TOSHIBA USIO21 serial port module

5SHY35L4520 5SXE10-0181 AC10272001R0101 Thyristor module

AUTOMATIONX AXLINK100 892.202988 module

| 720-23475-001 | 8030-ROM-122 | X-AO 16 51 |

| 720-23461-000 | CACR-SR20BB1AM | X-AO 16 01 |

| 720-21901-003 | 6SC6103-0SG31 | X-DO 12 51 |

| 712-404056-00 | 6SC9811-4BF10 | X-DO 12 02 |

| 710-806051-01 | 6DD1683-0CH0 | X-DO 24 02 |

| 710-806050-01 | 8020-SCP-424 | X-DO 24 01 |

| 710-805314-00 | 8020-SCP-423 | X-DO 32 51 |

| 710-805000-50 | 8020-SCP-401 | X-DO 32 01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218