AMAT Applied Materials 0100-90853伺服控制模块

1.产 品 资 料 介 绍:

- 多模式伺服控制能力:支持位置控制、速度控制、扭矩控制三种核心模式,可根据不同工艺需求灵活切换。位置控制模式下,支持脉冲 / 方向、A/B 相正交脉冲等多种位置指令输入,定位精度达 ±0.1 脉冲当量(对应线性位移≤0.05μm,适配高精度工作台运动);速度控制模式下,转速调节范围 0-5000rpm,转速稳定度≤±0.05rpm,满足晶圆传输机械臂匀速运行需求;扭矩控制模式下,扭矩控制范围 0-10N・m,控制精度 ±2% 额定扭矩,可用于靶材调节机构的恒扭矩加载控制。

- 高性能信号处理与反馈:搭载 32 位高性能 DSP(数字信号处理器),运算频率≥200MHz,可快速处理位置、速度、扭矩反馈信号,动态响应时间≤5ms,确保伺服电机对指令的快速跟随。支持增量式编码器(最高分辨率 10000 线 / 转)、绝对式编码器(单圈分辨率 16384 线)及光栅尺(分辨率 0.1μm)等多种反馈器件接入,通过实时采集反馈信号形成闭环控制,有效补偿机械间隙、负载扰动等因素导致的控制误差,位置控制重复精度≤±0.3μm。

- 智能抗干扰与稳定性优化:内置自适应 PID 调节算法,可根据负载变化(如晶圆传输时的负载增减)自动优化 PID 参数,避免超调与振荡,确保电机运动平稳(运动过程中振动量≤0.05g)。采用多重信号滤波技术,包括电流环低通滤波、位置环卡尔曼滤波,可有效抑制电磁干扰(EMI)与机械振动对反馈信号的影响,信号信噪比≥60dB。同时具备电源波动补偿功能,当输入电压在 DC 24V±10% 范围内波动时,输出控制精度保持不变,适配半导体车间复杂供电环境。

AMAT Applied Materials 0100-90853伺服控制模块 英文资料:

1、 Core positioning and system of the product

0100-90853 servo control module is a key control component in the semiconductor equipment servo control system of Applied Materials Company (AMAT), belonging to the "high-precision servo drive and control" product line. In core components such as wafer transfer robotic arms, coating and developing equipment workbenches, and target adjustment mechanisms in thin film deposition equipment that rely on micrometer or even nanometer level motion accuracy, the motion accuracy of servo motors directly determines process stability and product quality. This module serves as the "servo system brain" and is specifically designed to adapt to the servo motors of the AMAT Centura series etching equipment and Lithius Pro coating and developing equipment. By receiving instructions from the main controller, it achieves real-time and precise control of the servo motor speed, position, and torque, and is the core unit that ensures efficient, stable, and accurate operation of semiconductor equipment moving parts.

2、 Analysis of core functions and technical characteristics

Based on the strict requirements of semiconductor equipment servo systems for control accuracy (position error must be ≤± 0.5 μ m), response speed (dynamic response time ≤ 10ms), and stability, the core characteristics of this servo control module can be accurately disassembled into the following points:

Multi mode servo control capability: supports three core modes: position control, speed control, and torque control, which can be flexibly switched according to different process requirements. In position control mode, it supports multiple position command inputs such as pulse/direction, A/B phase orthogonal pulse, etc., with a positioning accuracy of ± 0.1 pulse equivalent (corresponding to linear displacement ≤ 0.05 μ m, suitable for high-precision worktable motion); In speed control mode, the speed adjustment range is 0-5000rpm, and the speed stability is ≤± 0.05rpm, which meets the requirement of uniform speed operation of the wafer transfer robotic arm; In torque control mode, the torque control range is 0-10N · m, and the control accuracy is ± 2% of the rated torque. It can be used for constant torque loading control of the target material adjustment mechanism.

High performance signal processing and feedback: Equipped with a 32-bit high-performance DSP (digital signal processor), the operating frequency is ≥ 200MHz, which can quickly process position, speed, and torque feedback signals. The dynamic response time is ≤ 5ms, ensuring that the servo motor can quickly follow instructions. Support the integration of various feedback devices such as incremental encoders (with a maximum resolution of 10000 lines/revolution), absolute encoders (with a single loop resolution of 16384 lines), and grating rulers (with a resolution of 0.1 μ m). By collecting feedback signals in real-time, closed-loop control is formed to effectively compensate for control errors caused by mechanical clearances, load disturbances, and other factors. The position control repeatability accuracy is ≤ ± 0.3 μ m.

Intelligent anti-interference and stability optimization: Built in adaptive PID adjustment algorithm, can automatically optimize PID parameters according to load changes (such as load increase or decrease during wafer transfer), avoid overshoot and oscillation, and ensure smooth motor motion (vibration amount ≤ 0.05g during motion). Adopting multiple signal filtering techniques, including current loop low-pass filtering and position loop Kalman filtering,

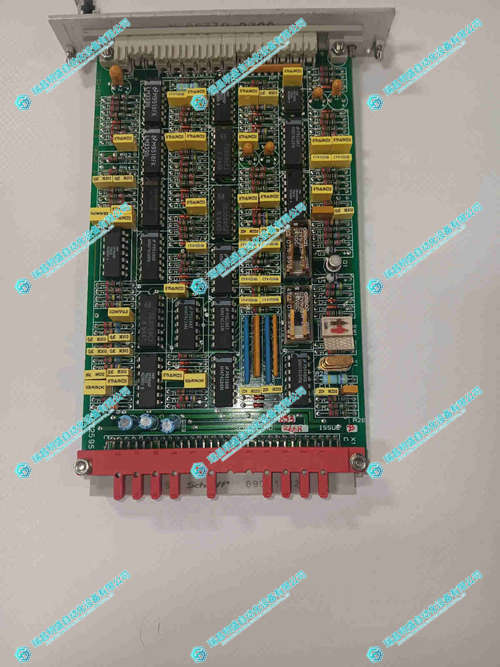

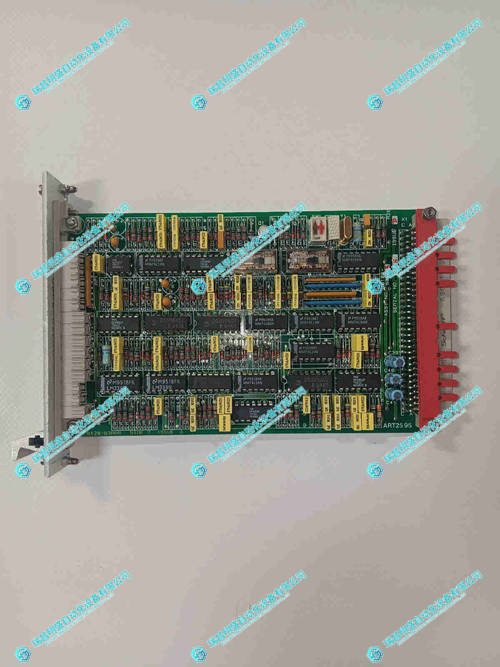

AMAT Applied Materials 0100-90853伺服控制模块 产品展示

产品视频

3.其他产品

GE DS3800HI0C1L1H 扩展板模块

SST PB3-VME-1-E V1.2.2 控制器模块

ABB 1TGE120021R0610 HW3 通信模块

4.其他英文产品

VIBRO IOCN 200-566-000-112 Vibration card

VIBRO MPC4 200-510-076-114 mechanical module

SST-PB3-CLX Resistance communication module

| 6ES5244-5AA31 | CACR-HR02BAB12 | IC660BBD101 |

| 6ES52431BA11 | 6SC9811-4CH00 | VME-I064 101864 |

| 6ES5243-1AA13 | CACR-HR20BBC | TRICONEX 4508 |

| 6ES5242-5AB21 | 6SC6506-0AA02 | PCD235A101 |

| 6ES5242-1AA32 | CACR-IR10SB | UNITROL 1010 |

| 6ES5241-1AD12 | 6SC6111-5DA00 | TRICONEX 3005 |

| 6ES5240-5AA31 | 6SC6500-0NA44 | SSA-G1018-0652 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218