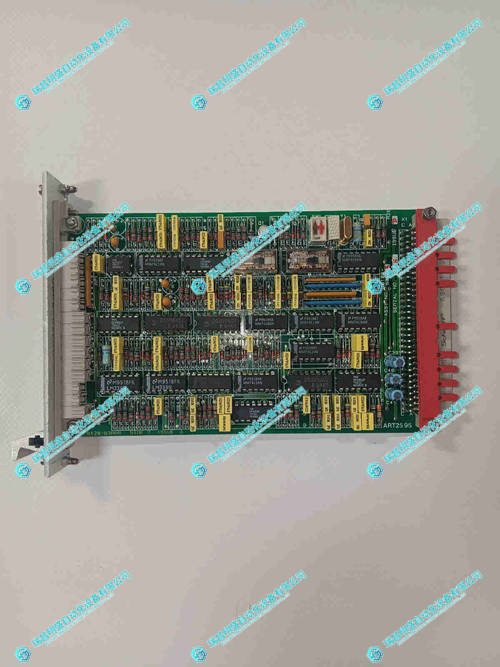

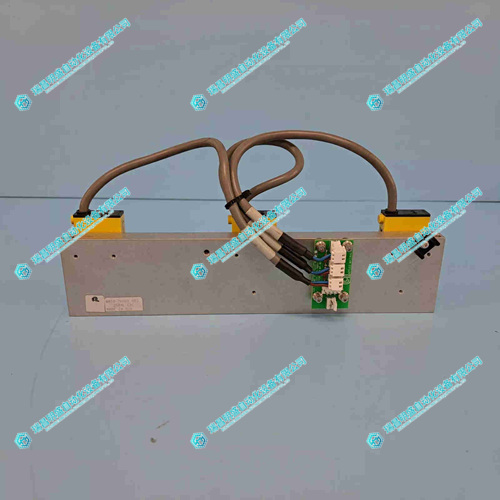

AMAT Applied Materials 0010-76968中心查找器模块

1.产 品 资 料 介 绍:

- 高精度光学定位检测:集成高分辨率 CMOS 图像传感器(像素尺寸 3.75μm×3.75μm,分辨率 2048×1080)与 650nm 红色激光光源,通过 “激光扫描 + 图像识别” 双模式定位 —— 激光沿晶圆边缘环形扫描,传感器捕捉反射光信号获取边缘轮廓数据,图像识别算法同步分析晶圆缺口 / 平边特征,定位精度达 ±2μm,重复定位精度≤±1μm,适配 8 英寸(200mm)、12 英寸(300mm)两种主流晶圆尺寸,无需更换硬件即可快速切换。

- 多维度坐标计算与校正:内置 32 位浮点运算处理器,可实时处理激光扫描获取的 2000 + 个边缘采样点,通过最小二乘法拟合晶圆圆心坐标,同时结合缺口 / 平边的角度信息(检测精度 ±0.1°),计算晶圆当前位置与设备基准轴的偏差(包括 X/Y 轴平移偏差、旋转角度偏差)。支持动态校正功能,当检测到晶圆因传输振动导致位置偏移时,可在 100ms 内重新计算坐标并输出调整指令,确保定位稳定性。

AMAT Applied Materials 0010-76968中心查找器模块 英文资料:

1、 Core positioning and system of the product

The 0010-76968 center finder module is a key positioning component in the semiconductor equipment wafer transfer and positioning system of Applied Materials Corporation (AMAT), belonging to the "high-precision wafer positioning and alignment" product line. In the core processes of semiconductor manufacturing, such as wafer transfer, etching, deposition, coating and development, the precise alignment of the wafer center with the equipment reference axis (with a deviation of ≤± 5 μ m) directly affects the process accuracy and product yield. This module serves as a "wafer positioning navigator" specifically designed for the wafer worktable of AMAT Centura series etching equipment and Lithius Pro coating and developing equipment. Through a combination of optical and mechanical positioning methods, it can identify wafer edges and notches/flat edges in real time, calculate wafer center coordinates, and guide worktable adjustments. It is the core positioning unit that ensures precise docking of wafers in various process stages.

2、 Analysis of core functions and technical characteristics

Based on the strict requirements of semiconductor equipment for wafer positioning accuracy (≤± 3 μ m), positioning speed (≤ 2s/wafer), and compatibility (compatible with 8/12 inch wafers), the core characteristics of the center finder module can be accurately disassembled into the following points:

High precision optical positioning detection: Integrated high-resolution CMOS image sensor (pixel size 3.75 μ m × 3.75 μ m, resolution 2048 × 1080) and 650nm red laser light source, through "laser scanning+image recognition" dual-mode positioning - laser scans along the edge of the wafer in a circular pattern, sensor captures reflected light signals to obtain edge contour data, image recognition algorithm synchronously analyzes wafer notch/flat edge features, positioning accuracy reaches ± 2 μ m, repeat positioning accuracy ≤ ± 1 μ m, suitable for two mainstream wafer sizes of 8 inches (200mm) and 12 inches (300mm), and can be quickly switched without hardware replacement.

Multi dimensional coordinate calculation and calibration: Equipped with a built-in 32-bit floating-point arithmetic processor, it can process more than 2000 edge sampling points obtained from laser scanning in real time. The wafer center coordinates are fitted using the least squares method, and combined with the angle information of notches/flat edges (detection accuracy ± 0.1 °), the deviation between the current position of the wafer and the equipment reference axis (including X/Y axis translation deviation and rotation angle deviation) is calculated. Support dynamic correction function. When the position deviation of the wafer is detected due to transmission vibration, the coordinates can be recalculated within 100ms and adjustment instructions can be output to ensure positioning stability.

AMAT Applied Materials 0010-76968中心查找器模块 产品展示

产品视频

3.其他产品

ABB 1TGE120021R0610 HW3 通信模块

ABB G2000A5.7ST 操作面板

HIMA H6200A 电路发射器

4.其他英文产品

UNIOP TCM08A communication card

SCHENCK VEG20400 weighing controller

5SHX1445H0002 3BHL000387P0101 IGCT module

| 6DD2920-0AW1 | CACR-SR20SB1BF | SCYC51010 |

| 6DD2920-0AW0 | CACR-SR30SBBFY100 | 3BHB003688R0101 |

| 6DD2920-0AV3 | CACR-PR01AC3ER | 44A751101-G01 |

| 6DD2920-0AV1 | CACR-UIR05050FD | 6ES5513-3LB11 |

| 6DD2920-0AV0 | 6SC6100-0NC11 | GDC806A0101 |

| 6DD2920-0AU1 | CACR-IR020202FC | UNS0119A-P,V101 |

| 6DD2920-0AU0 | CACR-SR30BE12G-E | 6ES5498-1AA51 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218