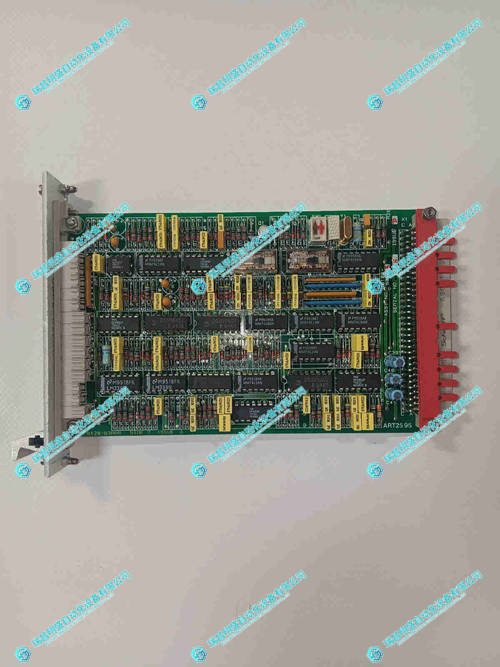

AMAT Applied Materials 0100-09302检测器模块

1.产 品 资 料 介 绍:

- 多参数集成检测能力:集成温度、振动、气体浓度、压力四类核心检测单元,可同步监测设备关键部位与工艺环境参数。温度检测采用高精度铂电阻(PT1000),检测范围 - 50~300℃,精度≤±0.3℃,适配腔体壁、电机外壳等部件温度监测;振动检测采用压电式加速度传感器,测量范围 0-50g,频率响应 1-1000Hz,精度≤±2% FS,可捕捉机械臂、工作台等运动部件的振动异常;气体浓度检测针对半导体常用工艺气体(如 O₂、CF₄、SiH₄),采用非色散红外(NDIR)原理,检测下限低至 1ppm,精度≤±5% FS,防止气体泄漏或浓度异常影响工艺;压力检测采用微型电容式压力传感器,测量范围 0-1MPa,精度≤±0.2% FS,适配气体管路、真空腔体的压力监测需求。

- 高速数据采集与传输:搭载 16 位高精度 ADC(模数转换器),每类检测参数的采样频率独立可调(最高达 1kHz),确保快速捕捉参数动态变化;配备 1 路 EtherNet/IP 工业以太网接口(传输速率 100Mbps,周期≤10ms)与 1 路 RS-485 接口,可将采集的监测数据实时上传至主控制系统与工厂 MES 系统,数据传输延迟≤5ms,满足设备实时调控与远程监控需求。同时支持数据本地缓存(内置 8GB 存储单元),可存储至少 30 天的历史监测数据,便于故障追溯与工艺分析。

AMAT Applied Materials 0100-09302检测器模块 英文资料:

1、 Core positioning and system of the product

The 0100-09302 detector module is a key detection component in the semiconductor equipment monitoring system of Applied Materials Corporation (AMAT), belonging to the "Multi Parameter Precision Detection and State Perception" product line. Real time monitoring of equipment operating status (such as component temperature and vibration) and process parameters (such as gas concentration and film thickness) is key to ensuring process stability and product quality in core processes such as etching, deposition, coating, and development in semiconductor manufacturing. This module serves as the "device sensing nerve endings" and is specifically designed to adapt to the AMAT Centura series etching equipment and Producer series deposition equipment. By integrating multiple detection units, it achieves real-time acquisition and anomaly recognition of multi-dimensional parameters of the equipment, providing accurate monitoring data support for the main control system of the equipment (such as the 0190-02506 controller). It is the core monitoring unit that ensures the safe and efficient operation of semiconductor equipment.

2、 Analysis of core functions and technical characteristics

Based on the strict requirements of semiconductor equipment for monitoring accuracy (such as temperature detection error ≤ ± 0.3 ℃), response speed (such as gas concentration detection response time ≤ 1s), and stability, the core characteristics of this detector module can be accurately disassembled into the following points:

Multi parameter integrated detection capability: integrating four core detection units including temperature, vibration, gas concentration, and pressure, which can synchronously monitor key parts of equipment and process environmental parameters. High precision platinum resistance (PT1000) is used for temperature detection, with a detection range of -50~300 ℃ and an accuracy of ≤± 0.3 ℃. It is suitable for temperature monitoring of components such as cavity walls and motor casings; The vibration detection adopts a piezoelectric accelerometer with a measurement range of 0-50g, a frequency response of 1-1000Hz, an accuracy of ≤± 2% FS, and can capture abnormal vibrations of moving parts such as robotic arms and workbenches; Gas concentration detection is aimed at commonly used process gases in semiconductors (such as O ₂, CF ₄, SiH ₄), using non dispersive infrared (NDIR) principle, with a detection lower limit as low as 1ppm and an accuracy of ≤± 5% FS, to prevent gas leakage or abnormal concentration from affecting the process; The pressure detection adopts a miniature capacitive pressure sensor with a measurement range of 0-1MPa and an accuracy of ≤± 0.2% FS, which is suitable for the pressure monitoring needs of gas pipelines and vacuum chambers.

High speed data acquisition and transmission: equipped with a 16 bit high-precision ADC (analog-to-digital converter), the sampling frequency of each type of detection parameter is independently adjustable (up to 1kHz), ensuring fast capture of dynamic changes in parameters; Equipped with one EtherNet/IP industrial Ethernet interface (transmission rate 100Mbps, cycle ≤ 10ms) and one RS-485 interface, the collected monitoring data can be uploaded in real time to the main control system and factory MES system, with a data transmission delay of ≤ 5ms, meeting the requirements of real-time control and remote monitoring of equipment. Simultaneously supporting local data caching (with built-in 8GB storage unit), it can store at least 30 days of historical monitoring data for easy fault tracing and process analysis.

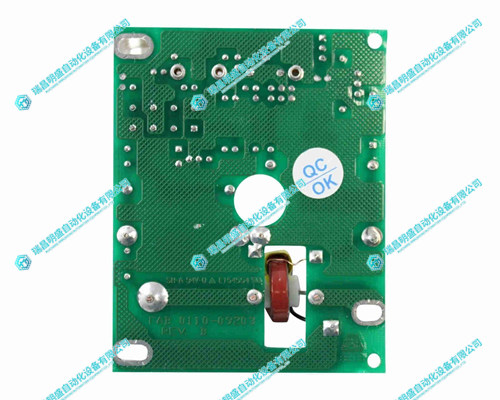

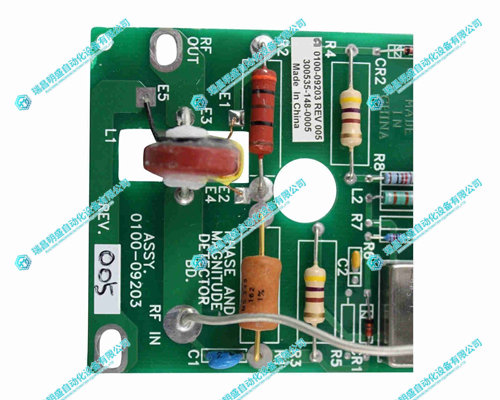

AMAT Applied Materials 0100-09302检测器模块 产品展示

产品视频

3.其他产品

SST PB3-VME-1-E V1.2.2 控制器模块

ABB 1TGE120021R0610 HW3 通信模块

ABB G2000A5.7ST 操作面板

4.其他英文产品

SST-PB3-CLX Resistance communication module

TVB3101-1/ISC CPU module

jdsu 2213-75TSLKTB Laser scanner

| 6ES5155-3UA11 | CACR-SR-15SB1AFY100 | 369-C101 |

| 6ES5155-3UA00 | 6SC6608-0BA01 | 511-0101-08B |

| 6ES5135-3UA11 | CACR-SR05BB1AF | GDC801B101 |

| 6ES5135-3KA13 | 6SC9821-0CG00 | TRICONEX MP2101 |

| 6ES5102-8MA02 | 6SC6140-OFF00 | 3BHB003154R0101 |

| 6ES5101-8UB13 | CACR-JU036A2A | UNS0119A-P V101 |

| 6ES5101-8UA12 | CACR-SR02AB2ER | GVC736CE101 |

| 6ES5095-8ME01 | 6SC9830-0HG20 | PCD244A101 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218