AMAT Applied Materials 0100-71047主框架互锁模块

1.产 品 资 料 介 绍:

- 电控柜安全联锁:安装于设备主电控柜柜门,监测柜门启闭状态。当柜门未完全闭合或非授权开启时,立即切断柜内高压电路(如射频电源、加热电源),防止人员接触带电部件引发触电事故。

- 工艺腔室舱门防护:适配刻蚀机、沉积设备的工艺腔室舱门,与腔室压力传感器联动。若舱门在真空未解除或工艺运行中开启,模块快速切断腔室动力源,避免工艺气体泄漏或真空环境破坏导致的安全风险。

- 高压模块安全管控:用于设备高压模块(如离子注入电源、静电吸盘高压单元)的外壳联锁,当外壳开启时强制断开高压输出,同时触发声光报警,提醒现场人员远离危险区域。

- 主机设备适配:广泛应用于 AMAT Centura 刻蚀系统、Endura 沉积平台、Producer 薄膜沉积设备及离子注入机等中高风险半导体设备。

- 配套模块兼容:与 AMAT 0225-01622 控制器、0100-20001 电子接口模块、安全光栅(如 Sick C40E 系列)直接对接,形成 “状态监测 - 联锁控制 - 报警反馈” 的闭环安全体系。

- 协同系统联动:支持与工厂安全管理平台(如 EHS 监控系统)数据交互,实时上传联锁触发记录与故障信息,便于安全事件追溯与设备安全状态评估。

- 安装前准备:确认安装区域洁净度符合 Class 100 标准,清除粉尘与金属碎屑;检查模块外观无损伤,接口无氧化;准备专用安全线缆(截面积≥1.5mm²,绝缘等级≥600V)、扭矩扳手(精度 ±5%)及防静电工具。

- 硬件安装:将模块固定在设备电控柜 DIN 导轨上(与高压部件间距≥30cm,避免电磁干扰);连接冗余安全电源(确保正负极无反接,接地电阻≤0.5Ω);按接口定义连接联锁输入(门开关、光栅)与安全输出(动力切断继电器),线缆需做标识区分,避免误接。

- 调试与验证:通过 AMAT 安全配置软件登录模块,设置联锁逻辑(如 “柜门开启→切断高压”“舱门开启→切断腔室电源”);模拟各类异常场景(如手动开启柜门、断开安全光栅),验证模块是否在 10ms 内触发安全动作,同时检查报警信号是否正常输出;调试完成后锁定模块参数,防止非授权修改。

AMAT Applied Materials 0100-71047主框架互锁模块 英文资料:

1. Core application areas

As the "first line of defense" for device security, this module mainly serves the security protection of the main framework of semiconductor equipment and hazardous areas:

Electrical control cabinet safety interlock: installed on the main electrical control cabinet door of the equipment to monitor the opening and closing status of the cabinet door. When the cabinet door is not fully closed or opened without authorization, immediately cut off the high-voltage circuit inside the cabinet (such as RF power supply, heating power supply) to prevent personnel from touching live parts and causing electric shock accidents.

Process chamber door protection: Suitable for process chamber doors of etching machines and deposition equipment, linked with chamber pressure sensors. If the cabin door is not evacuated or opened during process operation, the module quickly cuts off the chamber power source to avoid safety risks caused by process gas leakage or vacuum environment damage.

High voltage module safety control: used for the shell interlocking of equipment high voltage modules (such as ion injection power supply, electrostatic suction cup high voltage unit). When the shell is opened, the high voltage output is forcibly disconnected, and an audible and visual alarm is triggered to remind on-site personnel to stay away from dangerous areas.

2. Adapt devices and systems

Host equipment adaptation: widely used in medium and high-risk semiconductor equipment such as AMAT Centura etching system, Endura deposition platform, Producer thin film deposition equipment, and ion implantation machine.

Compatibility with supporting modules: Directly interface with AMAT 0225-01622 controller, 0100-20001 electronic interface module, and safety grating (such as Sick C40E series) to form a closed-loop safety system of "state monitoring interlocking control alarm feedback".

Collaborative system linkage: supports data exchange with factory safety management platforms (such as EHS monitoring systems), real-time uploading of interlocking trigger records and fault information, facilitating safety event tracing and equipment safety status assessment.

4、 Operation standards and maintenance management

1. Installation and commissioning process

Preparation before installation: Confirm that the cleanliness of the installation area meets Class 100 standards, and remove dust and metal debris; Check the appearance of the module for damage and the interface for oxidation; Prepare specialized safety cables (cross-sectional area ≥ 1.5mm ², insulation level ≥ 600V), torque wrenches (accuracy ± 5%), and anti-static tools.

Hardware installation: Fix the module on the DIN rail of the equipment control cabinet (with a distance of ≥ 30cm from high-voltage components to avoid electromagnetic interference); Connect redundant safety power supply (ensure that the positive and negative poles are not reversed, and the grounding resistance is ≤ 0.5 Ω); Connect the interlocking input (door switch, grating) and safety output (power cut-off relay) according to the interface definition, and label the cables to avoid misconnection.

Debugging and verification: Log in to the module through AMAT security configuration software and set interlocking logic (such as "cabinet door open → cut off high voltage" and "cabin door open → cut off chamber power"); Simulate various abnormal scenarios (such as manually opening cabinet doors, disconnecting safety barriers), verify whether the module triggers safety actions within 10ms, and check whether the alarm signal is output normally; Lock module parameters after debugging to prevent unauthorized modifications.

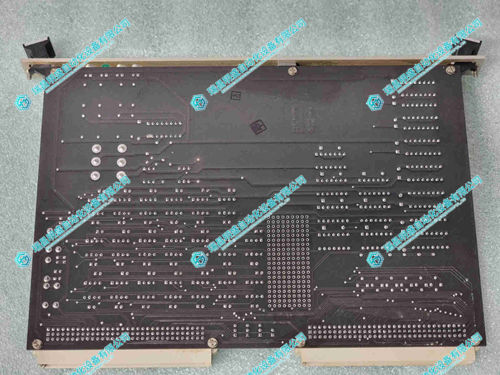

AMAT Applied Materials 0100-71047主框架互锁模块 产品展示

产品视频

3.其他产品

ABB UFC933A102 3BHE048062R0102 电路板

Yokogawa YHC5150X 手持通讯器

A-B 1734-ACNR 网络适配器

4.其他英文产品

IC698CPE020 Gas turbine module

METSO IOP111 module

METSO IOP302 Numerical control module

| 6ES5981-0GB11 | 6DD1684-0EB0 | TRICONEX 3706A |

| 6ES5981-0EA11 | 193X741AAG02 | TRICONEX 3663 |

| 6ES5980-3BC41 | 22-8875-004 | TRICONEX 3603T |

| 6ES5980-0AE11 | 30-07420-02 | TRICONEX 3625 |

| 6ES5955-5LB11 | 193X801DAG03 | TRICONEX 3636T |

| 6ES5955-3NC41 | 531X121PCRAAG1 | TRICONEX 3674 |

| 6ES5955-3LF41 | 531X113PSFARG1 | 060-00874-0006 |

| 6ES5951-7ND51 | 76-111301-00 | MC801-200-08 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218