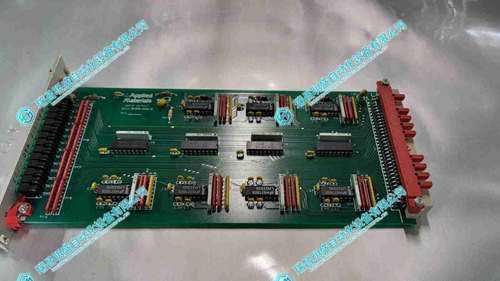

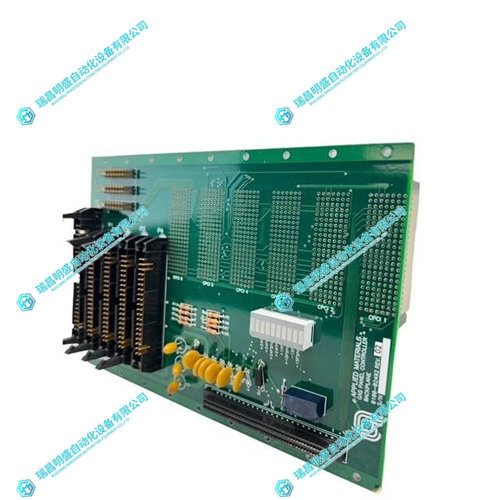

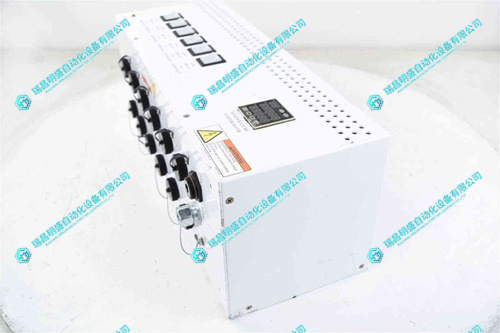

AMAT Applied Materials 0190-24680 面板温度控制器

1.产 品 资 料 介 绍:

AMAT Applied Materials 0190-24680 面板温度控制器 英文资料:

AMAT Applied Materials 0190-24680, with its high-precision and high stability temperature control capabilities, is widely used in multiple key areas of semiconductor manufacturing and related fields. The specific application scenarios and functional roles are as follows:

1. Semiconductor manufacturing equipment

In various semiconductor manufacturing equipment, this controller is the core executing component for temperature control. Its main purpose is to accurately control the temperature of process chambers, gas pipelines, substrate stages, and heating plates. In process chamber control, stabilizing the temperature inside the chamber ensures that the wafer is uniformly heated during deposition, etching, and other processes, avoiding inconsistent surface process effects caused by temperature differences; In gas pipeline temperature control, it can prevent gas from condensing or changing its properties due to temperature changes during transmission, ensuring the stability of gas transportation; For substrate stages and heating plates, precise temperature control can provide a uniform heating environment for the substrate, directly affecting the reaction effect between the substrate and process materials, thereby ensuring the performance and quality of semiconductor devices.

2. Chemical vapor deposition (CVD) system

In CVD systems, the reaction chamber temperature is a key factor affecting film growth. By adjusting the reaction chamber temperature, 0190-24680 achieves precise control over film growth rate, composition uniformity, and stress characteristics. When it is necessary to increase the growth rate of thin films, the reaction chamber temperature can be appropriately raised within the allowable range of the process to accelerate the chemical reaction process; If pursuing higher uniformity of components, it is necessary to control the temperature within a very small fluctuation range to ensure that the reaction proceeds in a stable environment; Meanwhile, reasonable temperature regulation can effectively control the internal stress of the film, reduce problems such as film cracking and detachment, and improve the quality of the film and the reliability of the device.

3. Physical Vapor Deposition (PVD) System

In PVD systems, 0190-24680 is mainly used to control the temperature of sputtering sources, substrate heating stages, and baffle heaters. For sputtering sources, a stable temperature can ensure uniform evaporation rate of the target material during the sputtering process, avoiding uneven film thickness caused by temperature fluctuations; The temperature control of the substrate heating table directly affects the adhesion between the film and the substrate. By accurately adjusting the temperature, the crystallization quality of the film can be optimized and the physical properties of the film can be improved; The temperature control of the baffle heater can prevent the deposition of materials on the baffle surface due to low temperature, ensure the normal switching function of the baffle, and avoid interference with the sputtering process.

4. Etch System

The stability of the cavity wall temperature and electrode temperature is crucial for the etching effect during the etching process. By managing the temperature of the cavity wall, 0190-24680 can prevent material deposition or damage to the cavity wall due to high or low temperature, while maintaining the balance of gas chemical reactions inside the cavity, ensuring the accuracy of etching rate and etching pattern; In terms of electrode temperature control, stable electrode temperature can ensure uniform distribution of ion energy, avoid problems such as uneven etching and etching depth deviation caused by electrode temperature fluctuations, and improve the stability and consistency of the etching process.

AMAT Applied Materials 0190-24680 面板温度控制器 产品展示

产品视频

3.其他产品

MKS 979B-01-0013 真空传感器

PPD117A3011 3BHE030410R3011激励控制器模块

3500/91-02-00 190782-01 通信网关模块

4.其他英文产品

BENTLY 3500/05-02-04-00-00-00 Monitor framework

BENTLY 3500/22M 138607-01 Monitor module

BENTLY 3500/53 133388-01 Monitor card

| 745-W2-P15-G1-LO-A-R | 8030-RIM-331 | X-FTA 003 02L 02R |

| 735-5-5-LO-485 | 8030-RIM-25 | X-FTA 002 02L 02R |

| 735-5-5-HI-485 | 8030-RIM-144 | X-FTA 002 01L 01R |

| 735-5-5-125-485-DEMO | 8030-RIM-143 | X-FTA 001 02L |

| 735-5-1-LO-485 | 8030-RIM-141 | X-FTA 001 01L |

| 735-5-1-HI-485 | 8030-ROM-141 | X-MIO 7/6 01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218