AMAT Applied Materials 0010-30366监视器

1.产 品 资 料 介 绍:

- 高分辨率与色彩还原能力:采用工业级高分辨率屏幕(推测分辨率不低于 1920×1080),像素密度达 100 PPI 以上,可清晰显示设备参数(如温度、压力、流量)的小数点后两位数据;同时具备 16.7M 真彩色显示能力,色彩偏差≤2ΔE,能精准还原工艺曲线、腔室状态图等彩色界面,帮助操作人员快速识别数据异常。

- 宽视角与高亮度设计:水平与垂直可视角度均≥178°,适配半导体设备操作间多工位观察场景,避免因视角偏差导致的数据误读;屏幕亮度≥500 cd/㎡,对比度≥1000:1,即使在洁净车间强光环境下(如顶部 LED 照明),仍能保持画面清晰,无反光、泛白现象。

- 高响应速度与稳定显示:屏幕响应时间≤5ms,无拖影现象,可流畅显示高频刷新的实时数据(如晶圆传输进度、工艺参数动态曲线);同时具备抗闪烁技术,刷新率稳定在 60Hz,长时间观看不易引发操作人员视觉疲劳,适配半导体设备 24 小时连续运行的使用场景。

- 多信号源兼容与切换:支持 VGA、DVI、HDMI、DisplayPort 等多种接口,可同时接入设备控制系统(如 PLC、工控机)、摄像头(如腔室内部监控摄像头)、传感器数据终端等多类信号源;配备一键信号切换功能,操作人员通过面板快捷键或触摸屏,可在 0.5 秒内完成不同信号源切换,快速查看设备运行界面、腔室实时画面等内容。

- 触控操作与定制化界面支持:采用工业级电容式触摸屏,支持 10 点触控,触摸精度≤±2mm,响应时间≤100ms,可实现参数设置、菜单选择、工艺启动 / 暂停等触控操作,替代传统物理按键,简化操作流程;同时支持 AMAT 设备定制化界面显示,可根据不同设备(如 CVD、PVD 设备)的需求,预设专属显示模板,将关键参数(如工艺腔温度、晶圆数量)置顶显示,提升操作效率。

- 数据存储与回放功能:内置存储模块(推测存储容量≥16GB),可自动存储设备运行数据界面截图、工艺曲线图表等内容,存储时间可自定义(如 1 小时 / 12 小时 / 24 小时);支持历史数据回放功能,操作人员可通过时间节点检索过往界面记录,便于追溯工艺异常原因,为设备故障排查提供视觉依据。

AMAT Applied Materials 0010-30366监视器 英文资料:

1、 High precision display performance: adapted to the data visualization needs of semiconductor devices

As the "visual center" of semiconductor equipment, this monitor has the core advantages of high precision and high definition at the display level, meeting the precise presentation requirements of equipment operation data and process status:

High resolution and color reproduction capability: Using an industrial grade high-resolution screen (estimated resolution not less than 1920 × 1080), with a pixel density of over 100 PPI, it can clearly display device parameters (such as temperature, pressure, flow rate) to two decimal places; At the same time, it has a 16.7M true color display capability with a color deviation of ≤ 2 Δ E. It can accurately reproduce color interfaces such as process curves and chamber status diagrams, helping operators quickly identify data anomalies.

Wide viewing angle and high brightness design: both horizontal and vertical viewing angles are ≥ 178 °, suitable for multi workstation observation scenarios in semiconductor equipment operation rooms, avoiding data misreading caused by viewing angle deviation; The screen brightness is ≥ 500 cd/㎡, and the contrast ratio is ≥ 1000:1. Even in strong light environments in clean workshops (such as top LED lighting), the image can still remain clear without reflection or whitening.

High response speed and stable display: screen response time ≤ 5ms, no ghosting phenomenon, smooth display of high-frequency refreshed real-time data (such as wafer transfer progress, process parameter dynamic curve); Simultaneously equipped with anti flicker technology, the refresh rate remains stable at 60Hz, making prolonged viewing less likely to cause visual fatigue for operators, and suitable for 24-hour continuous operation scenarios of semiconductor equipment.

2、 Strong functional adaptability: meeting the operational and monitoring needs of semiconductor equipment

This monitor is highly adaptable to the complex operation and monitoring scenarios of semiconductor equipment in terms of functional design, improving equipment maintenance efficiency and operational convenience

Multi signal source compatibility and switching: Supports multiple interfaces such as VGA, DVI, HDMI, and DisplayPort, and can simultaneously connect to device control systems (such as PLCs and industrial computers), cameras (such as indoor monitoring cameras), sensor data terminals, and other types of signal sources; Equipped with one click signal switching function, operators can switch between different signal sources within 0.5 seconds through panel shortcut keys or touch screen, and quickly view the device operation interface, real-time chamber screen and other content.

Touch operation and customized interface support: using industrial grade capacitive touch screen, supporting 10 point touch, touch accuracy ≤ ± 2mm, response time ≤ 100ms, can realize touch operation such as parameter setting, menu selection, process start/pause, replacing traditional physical buttons and simplifying the operation process; At the same time, it supports customized interface display for AMAT equipment, and can preset exclusive display templates according to the needs of different equipment (such as CVD and PVD equipment), displaying key parameters (such as process chamber temperature and wafer quantity) at the top to improve operational efficiency.

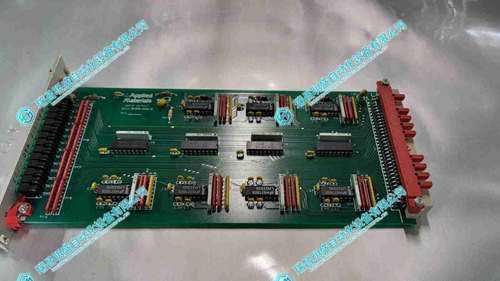

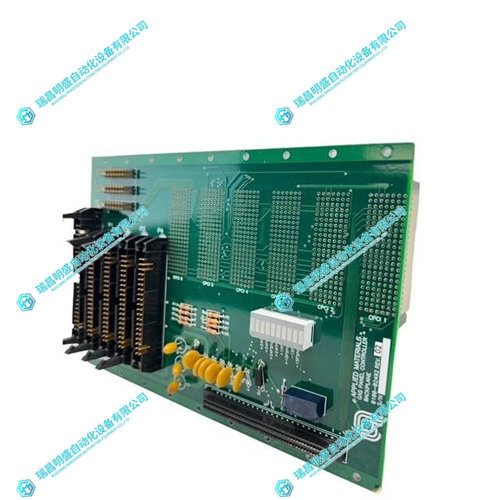

AMAT Applied Materials 0010-30366监视器 产品展示

产品视频

3.其他产品

A-B 349896-A01 逆变器模块

MLJ1005B010H00C 控制器模块

MC-4/11/03/400 伺服驱动器

4.其他英文产品

ABSOLUTE API4380-G Signal isolator

WATLOW ANAFAZE CLS216 cable

OMACO GF0-57CQD-002 Touch screen

| 710-663106-001 | 8020-SCP-111 | X-CPU 31 |

| 710-662033-00 | 8005-TT-116 | 4136J59-G01 |

| 710-659846-001 | 8005-ST-108 | 4136J58-G01 |

| 710-659846-00 | 8005-RT-108 | 4136J57G1 |

| 710-659412-00 | 8005-RIU-10 | 4136J57G0001 |

| 710-658956-00 | 8005-PR-4 | 4136J57-G01 |

| 710-658909-001 | 8005-NLU-10 | 4136J56-G01 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218