GIDINGS&LEWIS 502-03840-44伺服编码器

1.产 品 资 料 介 绍:

一、产品概述

二、技术特性

英文资料:

1、 Product Overview

GIDINGS&LEWIS 502-03840-44 is a crucial feedback component module in Giddings&Lewis servo control systems, designed specifically for servo motor matching. Its core value lies in building a bridge between the mechanical motion of servo motors and the electrical signals of control systems, accurately converting key mechanical motion information such as motor speed, angle, and displacement into electrical signals, and providing real-time feedback to the controller. In the entire servo system, it is like a pair of sharp "eyes and ears", providing indispensable basic data for achieving closed-loop control, ensuring that the system can adjust the control strategy in a timely manner according to the actual motion state, and guaranteeing the accuracy and stability of industrial equipment operation.

2、 Technical characteristics

High resolution ensures precise feedback: 502-03840-44 has excellent high-resolution characteristics, which can accurately capture the extremely subtle position changes and speed fluctuations of servo motors. Taking CNC machine tools as an example, when performing high-precision milling, the precise position signal provided can achieve micrometer level tool positioning accuracy, and the speed signal can ensure that the spindle speed is stable within a very small error range, fully meeting the strict requirements of CNC and automation equipment for high-precision control, laying a solid foundation for the production of precision components.

Real time feedback ensures dynamic performance: As the core component of closed-loop detection in servo systems, it can provide extremely fast feedback of motor motion status to the control system. During the operation of the equipment, if there is a speed deviation or position offset of the motor, the encoder can quickly capture and transmit the signal to the controller, which then responds and adjusts the motor operating parameters. This real-time feedback mechanism greatly enhances the dynamic response capability of the motion process, effectively avoiding motion misalignment caused by delays and ensuring stable and smooth operation of the device.

Interface compatibility simplifies system integration: This encoder is seamlessly and directly compatible with G&L control systems and servo drive units, and supports standard feedback signal output. Whether in building a new system or upgrading an old system, engineers do not need to perform complex interface adaptation work and can directly integrate it into the existing system architecture, reducing technical difficulties and debugging time in the system integration process, lowering development costs, and improving system construction efficiency.

Anti interference design is suitable for harsh environments: fully considering the complex and harsh working conditions of industrial sites, 502-03840-44 has undergone comprehensive anti-interference design. In industrial plants filled with a large number of electromagnetic equipment, the internal circuit design and shielding measures can effectively resist strong electromagnetic interference, ensuring accurate signal transmission; At the same time, in response to common industrial environmental factors such as mechanical vibration, the encoder adopts measures such as shock absorption and reinforcement in structural design to ensure stable operation in vibration environments, reduce measurement errors and equipment failures caused by environmental interference, and provide reliable guarantees for the continuity of industrial production.

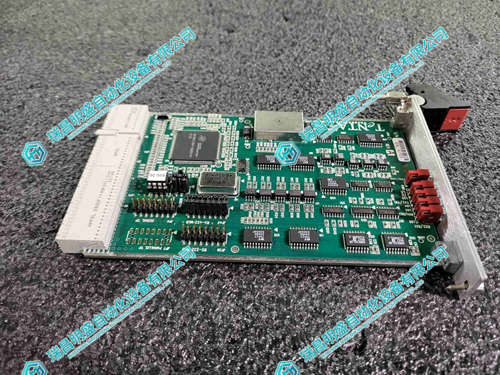

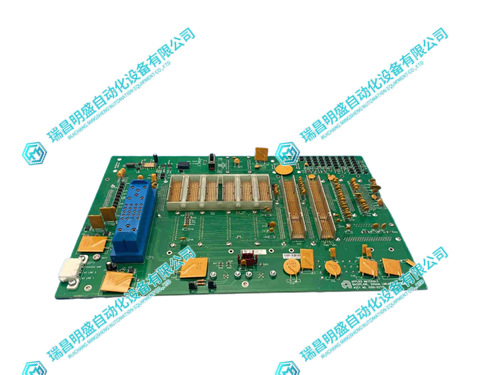

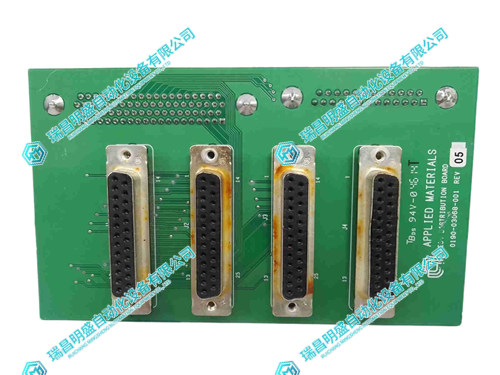

2.产 品 展 示

3.其他产品

4.其他英文产品

GE D20 EME 10BASE-T Digital Control Modu

RADISYS 451558-004 Communication Module

ABB UN0942b-P Programmable Controller

| 6ES5897-8QF01 | CACR-SR15BE12G-E | EXP-AM |

| 6ES5897-3QA21 | CACR-IR30SE | EXP-VID-B, |

| 6ES58972QA210KL1 | CACR-IR10SEDY20 | EPC-8AEPC-8B |

| 6ES5897-2PF11 | CACR-W37-FJ3ER | 44373702 |

| 6ES5897-2KB21 | CACR-SR-10SZ1SFY221 | EXM22 |

| 6ES58972AE110KL1 | CACR-CSL12L18AAB | 61-0475-20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218