GIDINGS&LEWIS M.1302.7764输入模块

1.产 品 资 料 介 绍:

产品概述

技术参数(典型特性)

英文资料:

Product Overview

In the process of industrial automation, Giddings&Lewis M.1302.7764, as an excellent industrial grade digital/analog input module, shoulders a critical mission. It is like a bridge connecting the real physical world with numerical control systems and automation control systems, capable of efficiently receiving signals from sensors, switches, and other input devices. Its core task is to accurately convert these external physical signals into digital or analog data that can be easily processed by the central control board. With this key function, it provides a solid data foundation for precise control of mechanical actions, smooth progress of production processes, and stable operation of monitoring systems, and is one of the core components for achieving precise control of industrial automation.

Technical parameters (typical characteristics)

Module type: Clearly positioned as a Digital/Analog Input Module, designed specifically for signal acquisition and conversion requirements in industrial automation scenarios, playing an indispensable role in front-end data acquisition in the entire control system architecture.

Number of input channels: With excellent scalability, it can usually support 8 to 16 input channels according to different system configuration requirements. This means that it can simultaneously connect multiple sensors or switch devices, meeting the diverse signal acquisition needs in complex industrial environments. Whether it is small automation equipment or large automation production lines, it can be flexibly adapted.

Signal type:

Digital input: It can easily handle switch signals, such as device start/stop button signals, limit switch signals, etc., and can quickly and accurately identify changes in device status; At the same time, it can efficiently process pulse signals, such as the pulses output by encoders, for precise measurement of equipment motion position and speed, providing key position and speed feedback data for automation control.

Analog input: Supports the acquisition of voltage and current signals. In industrial production, many sensors transmit measurement data through voltage or current changes. For example, the voltage signal output by a temperature sensor reflects the ambient temperature, and the current signal output by a pressure sensor reflects the pressure magnitude. This module can accurately collect and convert these analog signals for analysis and processing by the control system.

Sampling accuracy: For analog signal acquisition, it has a sampling accuracy of up to 16 bits. This means that it can perform extremely fine quantization processing on analog signals, accurately capturing and converting small changes in signals into digital quantities, providing high-precision data for control systems, thereby achieving precise control of industrial production processes, effectively reducing control errors, and improving product quality.

Response time: With microsecond level ultra fast response time, this feature makes it perform excellently in real-time control scenarios. In the process of industrial automation production, equipment status changes rapidly. This module can complete signal acquisition and conversion in a very short time, timely transmit the latest data to the central control board, ensure that the control system can respond quickly, and meet the high real-time requirements of control tasks, such as emergency braking control of high-speed equipment.

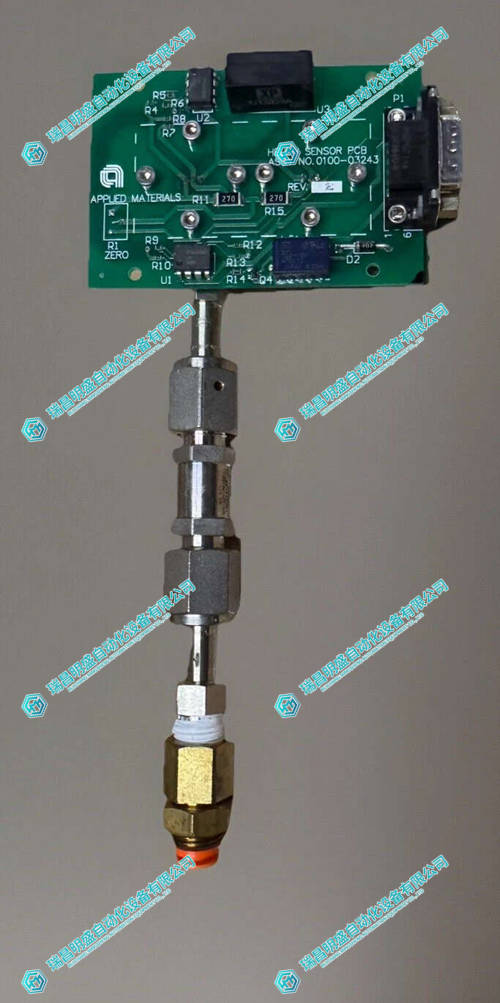

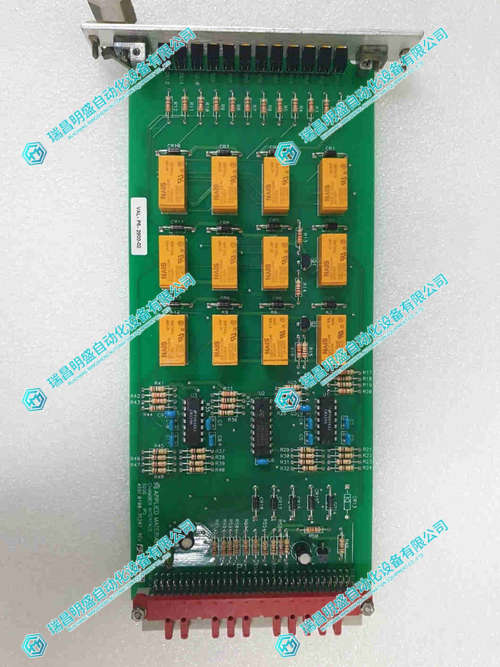

2.产 品 展 示

3.其他产品

4.其他英文产品

TOYOTA 57250-13300-71 Display Module

TOYOTA 00591-32004-81 Control Pulse Card

| 6ES5704-4CB00 | CACR-SR10SF1BFB | ATCA-4745 |

| 6ES5704-3BC50 | CACR-SR06TZ9SM-Y01A | EPC8-DX66-00-2 |

| 6ES5703-5CC00 | CACR-IR10SE | 115970-010,440 |

| 6ES5703-3CD20 | CACR-IR | 859-8150-002 |

| 6ES5703-1CC01 | CACR-SR44BC!CSY414A | PRE-913423 |

| 6ES5703-1BF00 | CACR-IR010101F | VM7830SYS |

| 6ES5701-0LA11 | CACR-10-101010F | OP1W03-0-0 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218