GIDINGS&LEWIS NSM2302 B24伺服电机

1.产 品 资 料 介 绍:

产品概述

技术特性(典型参数)

英文资料:

Product Overview

In the field of precision motion control in industrial automation, Giddings&Lewis NSM2302 B24 AC servo motor stands out with outstanding performance. As an ideal choice for high-precision and high dynamic response demand scenarios, it is widely used in core equipment such as CNC machine tools, industrial robots, and automated production lines. It works seamlessly with G&L's M.1015 series servo drives to build a complete and precise servo system, fundamentally ensuring the accuracy and stability of equipment motion control, and becoming an indispensable driving force in the process of industrial automation.

Technical characteristics (typical parameters)

Motor type: Clearly positioned as an AC servo motor, it has significant advantages in response speed and control accuracy compared to traditional motors, and is designed specifically for the strict control requirements of industrial automation.

Main functions:

Accurate output: able to provide precise speed, position, and torque output in a very short time according to system instructions. During CNC machining, the motor speed and torque can be quickly adjusted according to different cutting processes to ensure precise cutting of the tool; When industrial robots perform complex handling tasks, precise control of motor position ensures accurate grasping and placement actions.

Closed loop collaboration: Collaborate with servo drives to build a closed-loop control system, with built-in high-precision feedback adjustment mechanism. The driver adjusts the output signal in real-time based on the motor's operating status, and the motor promptly corrects its own operating parameters after receiving the signal. The two work closely together to effectively resist external interference and maintain high-precision operation at all times.

Structural design:

Compact body: Adopting a compact design concept, the overall volume is small, making it an excellent adaptation solution for automation equipment with compact spatial layout and limited installation space. It can be flexibly installed in small spaces without occupying too much equipment space.

High performance rotor: equipped with high-performance permanent magnet rotor, greatly improving the dynamic response capability of the motor. When the device starts, stops, or quickly switches motion states, the motor can quickly respond, shorten the action delay time, and improve the overall operating efficiency of the device.

Feedback method: Built in encoder/parser, real-time collection of key data such as motor position and speed, and feedback to the control system. With these precise feedback information, closed-loop control can operate efficiently, ensuring that the motor operation accuracy is always maintained at a very high level, meeting the strict requirements of industrial automation for equipment positioning accuracy.

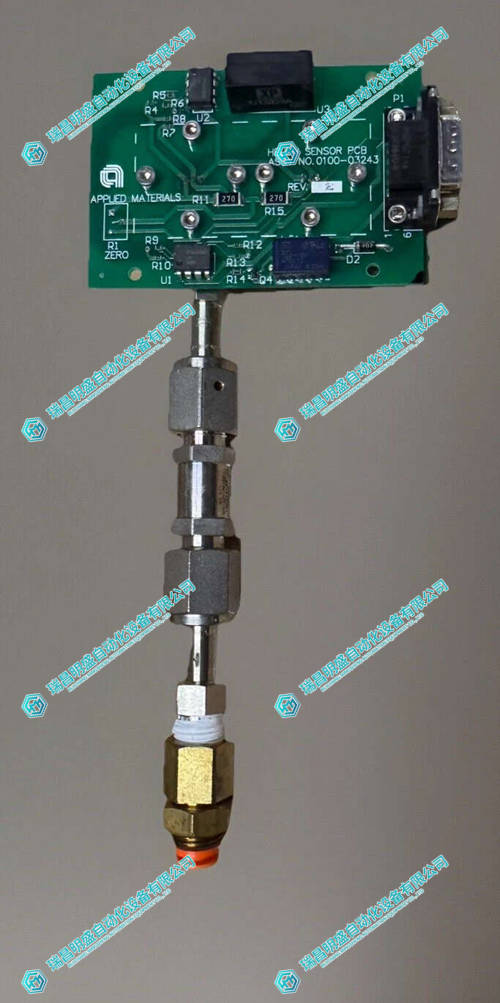

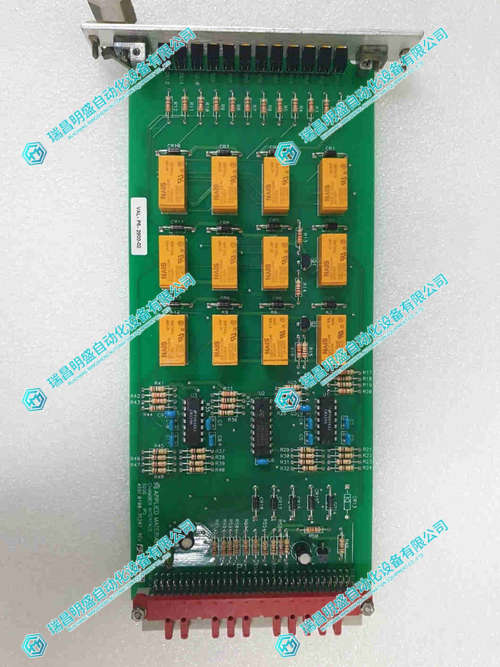

2.产 品 展 示

3.其他产品

4.其他英文产品

GIDINGS&LEWIS DSM175 servo drive

TOYOTA B10B1-TM2088N-01 Circuit Board

TOYOTA 57250-13300-71 Display Module

| 6ES5721-0CG30 | CACR-SR20BB1BF | 61-0175-10 |

| 6ES5721-0CC00 | CACR-IRA5A5A5F | 061-01666-0010 |

| 6ES5721-0BF00 | CACR-SR44SZ1SDY231 | EMC-BP8-EMC-PS |

| 6ES5721-0BB00 | CACR-SR15BB1CSY8 | 61-0367-37 |

| 6ES5714-3CF00 | CACR-SR05BA1AM | 148472-006 |

| 6ES5714-3CB00 | CACR-SR15SZ1SSY228 | C2SBI-RSYS-JD1 |

| 6ES5712-8BF00 | CACR-HR10UB-Y9 | EMC-BP12 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218