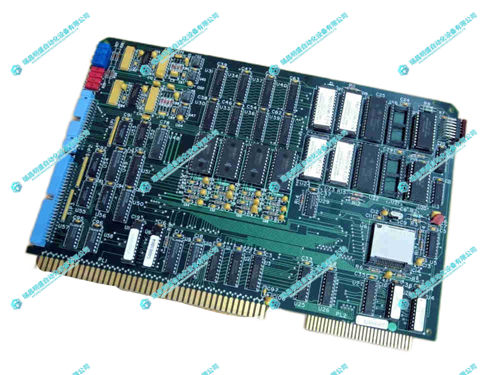

GIDINGS&LEWIS 58006167控制器模块

1.产 品 资 料 介 绍:

GIDDINGS & LEWIS 58006167 控制器模块介绍

一、产品概述

二、产品特点

英文资料:

Introduction to GIDINGS&LEWIS 58006167 Controller Module

In the complex architecture of industrial control systems, the GIDINGS&LEWIS 58006167 controller module occupies a central position, like the central gear of precision machinery, coordinating and driving the orderly operation of the entire system, and is the key to achieving industrial equipment automation and precise control.

1、 Product Overview

58006167, as an industrial controller module, is the "smart brain" of the system. It always maintains a keen perception of input module signals, whether it is device operating parameters captured by on-site sensors or status information feedback from switches, it can be accurately received. Subsequently, with the built-in complex logic operation rules and efficient control algorithms, these signals are deeply analyzed and processed, transforming abstract data into practical and feasible control strategies. Finally, quickly send instructions to the output module or driver module to drive various execution devices, such as motors, valves, etc., to accurately operate according to preset programs, thereby achieving the complete process of industrial equipment from basic monitoring to automation operation, ensuring the stable and efficient operation of the entire industrial control system.

2、 Product Features

High performance processing capability: Equipped with a powerful computing core, capable of simultaneously processing multiple sets of complex logical operation tasks. In large-scale automated production lines, facing the influx of a large amount of equipment status data, it can complete calculations in an instant, coordinate the sequence of actions and running rhythm of each device, ensure that the entire system is still efficient and stable under high load operation, avoid lagging or delay phenomena, and greatly improve production efficiency and product quality.

Modular design: Adopting a plug-in structure, this design greatly simplifies the system integration and maintenance process. During the system setup phase, technicians only need to easily insert modules into standard rack slots to quickly complete the installation, significantly reducing the project deployment cycle. During the operation of the equipment, if a module malfunctions, maintenance personnel do not need to disassemble the entire system on a large scale. They only need to remove the faulty module and replace it with a new one to quickly restore system operation, reduce downtime, and minimize production losses for the enterprise. In addition, when enterprises need to upgrade system functions for business expansion, they can easily add new modules to achieve flexible system expansion and meet the constantly changing production needs of the enterprise.

High speed signal processing: Equipped with high-speed signal processing circuits, it can receive input signals at extremely fast speeds and complete signal analysis and processing in nanoseconds. In industrial scenarios that require extremely high real-time performance, such as CNC machining processes, small changes in tool position need to be immediately fed back and adjusted. The 58006167 module can respond quickly to ensure that the output equipment executes instructions in a timely manner, achieving real-time and precise control of on-site equipment and effectively avoiding machining errors or equipment failures caused by signal processing delays.

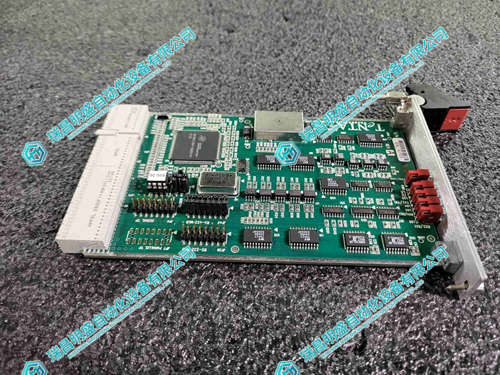

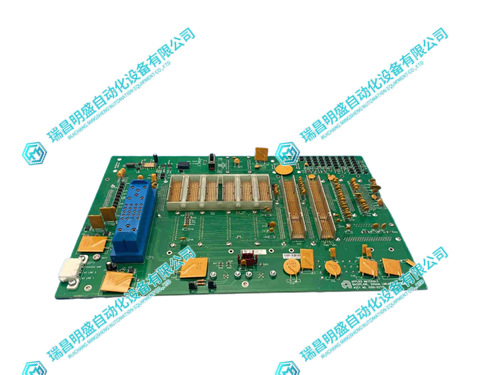

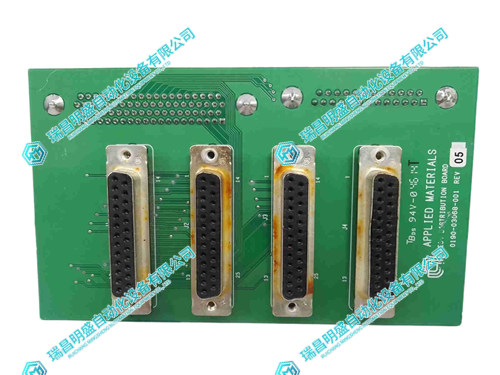

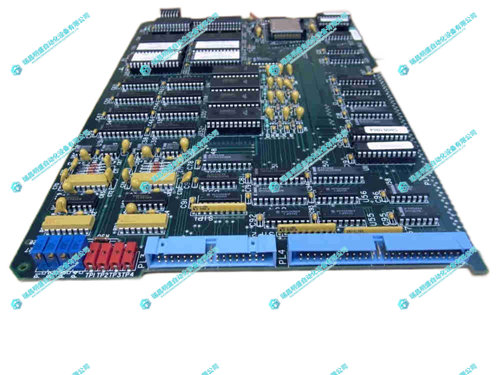

2.产 品 展 示

3.其他产品

4.其他英文产品

ASEA 57310256-BA circuit board

GESVDU-1D-8946 Input/Output Module

REF615E-E HBFEAEAGABCCANC11E Measurement

| 269PLUS-100P-120 | SS9RMP | 710-679375-002 |

| 269PLUS-100N-120 | SV3440-01000 | 92-005649-XXX |

| 269-120N-120VAC | S5101 | 710-611536-000 |

| 269-10C-HI | SP11000-443C2 | 712-404057-00 |

| 269-10C-240 | 54404-00 | F31X139APMAGG3 |

| 269-10C-125VDC | CACR-SR-03SZ1SS | 720-24399-001 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218