1.产 品 资 料 介 绍:

HG3F-FT22TF-W显示面板产品说明

HG3F-FT22TF-W是和泉(IDEC)推出的工业级彩色触控显示面板,隶属于MicrO/I® HG3F系列,核心定位为工业控制系统的人机交互核心。产品融合高清显示、稳定通信、可靠防护等多重优势,可实现工业设备运行状态的实时监控、参数设置与指令下发,广泛适配各类工业自动化控制场景。产品特点如下:

一、产品特点

- 高清可视化触控体验:搭载10.4英寸256色TFT LCD显示屏(分辨率640×480),浅灰色机身设计简洁大气;屏幕显示清晰细腻,可精准呈现运行数据、状态图标及操作界面,搭配灵敏触控响应,操作便捷直观,大幅提升人机交互效率;

- 多协议兼容稳定通信:不仅支持Allen-Bradley DH485通信协议,还兼容RS-232/RS-422等多种串口标准,可与SLC 500系列PLC等主流工业控制设备无缝对接,实现控制指令与运行数据的高速稳定传输,保障系统协同可靠工作;

- 工业级高可靠性防护:采用工业级加固设计,面板防护等级达IP66,可抵御强力喷射与粉尘侵入,适配恶劣工业环境;具备优异的抗电磁干扰能力,通过IEC/EN 61131-2等多项EMC标准认证,工作温度范围覆盖0~50℃,可耐受振动、冲击等严苛工况;

- 灵活安装与便捷运维:机身结构紧凑,背后安装深度仅49.6mm,支持嵌入式或面板式安装,轻松集成于工业控制柜或操作台,节省安装空间;支持背光现场更换,配备参数备份/恢复功能,搭配Windo/I-NV2编程软件,大幅降低调试与维护难度;

- 实用功能丰富适配广:内置实时时钟,具备报警日志记录、趋势显示及柱状图/位图展示等功能,可满足多样化数据呈现需求;支持24V DC宽压供电(电压波动80%~120%),适配工业现场复杂供电环境,广泛匹配各类自动化控制场景。

二、核心应用领域

- 工业自动化生产线:适配汽车零部件装配线、电子元件加工线等自动化生产线,作为人机交互终端,实现生产线运行状态监控、工艺参数设置及故障报警提示,保障生产流程稳定;

- 数控机床与加工中心:用于机床控制系统的人机交互,实时显示刀具位置、加工进度等参数,支持加工程序调用与参数调整,提升机床操作便捷性与加工精度;

- 电力与能源监控系统:适用于变电站、储能电站等能源场景的监控终端,显示电力设备运行参数(电压、电流、功率等),支持远程控制指令下发与故障预警,保障能源系统安全运行;

- 专用工业设备:适配包装机、码垛机器人、自动化仓储设备等专用工业设备,实现设备运行状态的可视化监控与操作控制,提升设备自动化水平与运维效率。

HG3F-FT22TF-W显示面板 英文资料:

HG3F-FT22TF-W Display Panel Product Description

HG3F-FT22TF-W is an industrial grade color touch display panel launched by IDEC, belonging to MicrO/I ® The HG3F series is positioned as the human-machine interaction core of industrial control systems. The product integrates multiple advantages such as high-definition display, stable communication, and reliable protection, enabling real-time monitoring of industrial equipment operation status, parameter setting, and command issuance, and is widely applicable to various industrial automation control scenarios. The product features are as follows:

1、 Product Features

-High definition visual touch experience: Equipped with a 10.4-inch 256 color TFT LCD display screen (resolution 640 × 480), the light gray body design is simple and atmospheric; The screen display is clear and delicate, accurately presenting operational data, status icons, and operating interfaces. Coupled with sensitive touch response, the operation is convenient and intuitive, greatly improving the efficiency of human-computer interaction;

-Multi protocol compatible and stable communication: It not only supports Allen Bradley DH485 communication protocol, but also multiple serial port standards such as RS-232/RS-422, which can seamlessly interface with mainstream industrial control equipment such as SLC 500 series PLC, achieving high-speed and stable transmission of control instructions and operating data, ensuring reliable system cooperation and operation;

-Industrial grade high reliability protection: Adopting industrial grade reinforced design, the panel protection level reaches IP66, which can resist strong spraying and dust intrusion, and is suitable for harsh industrial environments; Has excellent anti electromagnetic interference capability, certified by multiple EMC standards such as IEC/EN 61131-2, with a working temperature range covering 0-50 ℃, and can withstand harsh working conditions such as vibration and impact;

-Flexible installation and convenient operation and maintenance: The body structure is compact, with a back installation depth of only 49.6mm, supporting embedded or panel installation, easily integrated into industrial control cabinets or workstations, saving installation space; Support on-site backlight replacement, equipped with parameter backup/recovery function, and paired with Windows/I-NV2 programming software, greatly reducing the difficulty of debugging and maintenance;

-Rich practical functions and wide adaptability: Equipped with a built-in real-time clock, it has functions such as alarm log recording, trend display, and bar chart/bitmap display, which can meet diverse data presentation needs; Supports 24V DC wide voltage power supply (voltage fluctuation of 80%~120%), suitable for complex power supply environments in industrial sites, and widely matches various automation control scenarios.

2、 Core application areas

-Industrial automation production line: adapted to automated production lines such as automotive parts assembly lines and electronic component processing lines, serving as a human-machine interaction terminal to achieve production line operation status monitoring, process parameter setting, and fault alarm prompts, ensuring stable production processes;

-Numerical Control Machine Tools and Machining Centers: Used for human-machine interaction in machine tool control systems, displaying real-time parameters such as tool position and machining progress, supporting machining program calls and parameter adjustments, and improving machine tool operation convenience and machining accuracy;

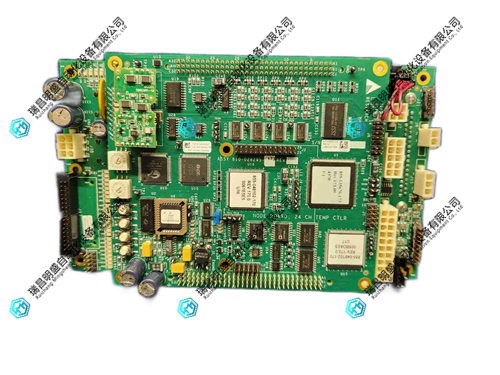

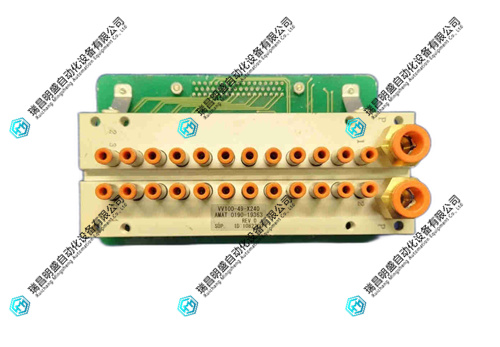

HG3F-FT22TF-W显示面板 产品展示

产品视频

3.其他产品

GE IS220PAICH2A 336A4940CSP11模拟输入模块

GE IS220PDIAH1A 336A4940CSP1数字输入模块

GE V7768-320001 350-9301007768-320001模块

4.其他英文产品

EI803F 3BDH000017R1 process control module

TOSHIBA HFAS11S communication card

TOSHIBA UTLH21 Communication module

| IS215UCVGH1A | HA42A6-R233 | IMDS001 |

| IS215UCVFH2AB | SE06200-000000 | IMASI03 |

| IS215ACLEH1C | S60300-NA | IMASOO1 |

| IS215ACLEH1B | SLO-SYN430P1 | INICT01 |

| IS215ACLEH1A | H3801 | 47545701 |

| IS200UCVGH1A | HH-J715-0000 | 067-10867-0001 |

| ICS TRIPLEX T3480 | SS2000IV | 6DD1842-0AA1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218