TEL Tokyo Electron CS1B85-372049-W1电机冲击模块

1.产 品 资 料 介 绍:

产品名称:

Tokyo Electron (TEL) CS1B85-372049-W1 电机冲击模块 — 产品应用领域详解

1. 半导体制造设备中的晶圆传输系统

关键作用:该模块在晶圆传输过程中,负责调节电机启动和停止时的冲击力度,确保晶圆平稳移动。

应用价值:防止传输中因冲击或震动导致的晶圆位移、破损或位置偏差,保障晶圆的完整性和后续工艺的稳定性。

典型场景:晶圆搬运机器人、传送带启动/停止控制、输送机构的减震优化等。

2. 自动化机械运动控制

动态调节:该模块通过控制电机冲击,优化机械臂或输送系统的启动与停止过程。

效果提升:有效降低机械系统的震动和冲击,提升设备的运行平稳性与重复定位精度。

应用示例:自动化装载机、精密机械手臂、电机驱动的输送装置等。

3. 设备振动抑制与性能优化

振动缓冲:通过精确控制电机冲击力,减少机械冲击带来的振动,保护设备内部敏感部件。

延长寿命:有效避免因冲击频繁造成的机械疲劳和损伤,延长设备使用寿命。

维护便利:降低故障率,减少维修频次和停机时间,提升生产线稼动率。

4. 高精度定位系统支持

动作平稳:在晶圆装载、卸载及搬运环节,保证动作柔和稳定,避免定位误差。

工艺保障:稳定的定位支持高精度工艺执行,提升产品良率。

应用环境:微细加工设备、光刻机、刻蚀设备等需要高精度机械定位的场合。

英文资料:

Tokyo Electron (TEL) CS1B85-372049-W1 Motor Shock Module - Product Application Field Detailed Explanation

1. Wafer transfer system in semiconductor manufacturing equipment

Key role: This module is responsible for adjusting the impact force during the start and stop of the motor during wafer transfer, ensuring smooth movement of the wafer.

Application value: To prevent wafer displacement, damage, or positional deviation caused by impact or vibration during transmission, ensuring the integrity of the wafer and the stability of subsequent processes.

Typical scenarios: wafer handling robots, conveyor belt start/stop control, shock absorption optimization of conveying mechanisms, etc.

2. Automated mechanical motion control

Dynamic adjustment: This module optimizes the start and stop process of the robotic arm or conveyor system by controlling the motor impact.

Effect improvement: Effectively reduce the vibration and impact of the mechanical system, improve the smooth operation and repeated positioning accuracy of the equipment.

Application examples: Automated loaders, precision robotic arms, motor-driven conveyors, etc.

3. Equipment vibration suppression and performance optimization

Vibration buffering: By precisely controlling the impact force of the motor, the vibration caused by mechanical impact is reduced, and sensitive components inside the equipment are protected.

Extend lifespan: Effectively avoid mechanical fatigue and damage caused by frequent impacts, and extend the service life of equipment.

Easy maintenance: reduce failure rate, minimize maintenance frequency and downtime, and improve production line utilization rate.

4. High precision positioning system support

Smooth operation: Ensure smooth and stable operation during wafer loading, unloading, and handling to avoid positioning errors.

Process assurance: Stable positioning supports high-precision process execution, improving product yield.

Application environment: In situations where high-precision mechanical positioning is required, such as microfabrication equipment, lithography machines, etching equipment, etc.

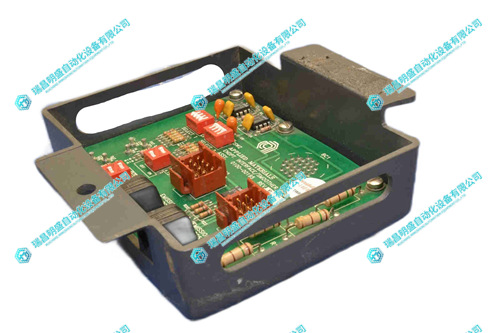

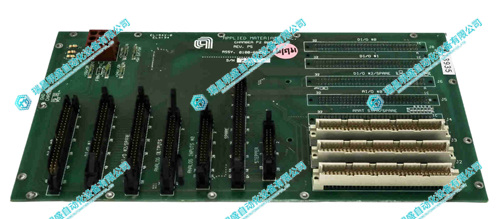

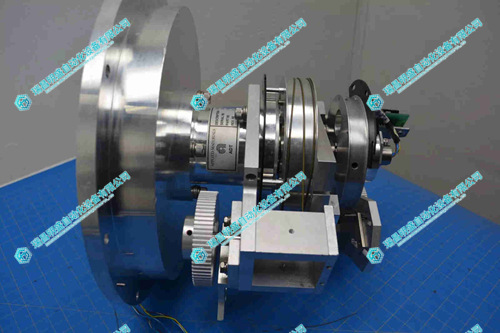

2.产 品 展 示

3.其他产品

4.其他英文产品

CI860K01 3BSE032444R1 power module

CI871AK01 3BSE092693R1 interface module

VE5010 Logic Controller Module

| 565-5-5-O-A | 6SC6110-OGB00 | NASI02 |

| 565-5-5-M | 6SC6901-0EA00-Z | NCTM01 |

| 565-5-5-A | 6SC6140-1AG00 | NASM01 |

| 5645-039 | 6SC6101-5B-Z | NCOM03 |

| 5645-027 | 6SC9112-3BA05 | INNIS01 |

| 5645-024 | 6SC6100-0AA80 | IMMFP02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218