AMAT Applied Materials 0021-07089夹盖组件

1.产 品 资 料 介 绍:

AMAT Applied Materials 0021-07089 夹盖组件

一、核心规格与技术参数

二、核心组件与功能

AMAT Applied Materials 0021-07089夹盖组件 英文资料:

AMAT Applied Materials 0021-07089 Clamp Cover Component

AMAT 0021-07089 is a vacuum sealed clamping cover component designed specifically for semiconductor equipment process chambers. Its core function is to achieve precise clamping, sealing, and rapid opening and closing of the process chamber top cover. It is compatible with vacuum process chambers such as Centura and Endura platforms for etching and thin film deposition, ensuring the sealing reliability and operational convenience of the chamber in high vacuum and strong corrosive environments.

1、 Core specifications and technical parameters

Detailed description of project specifications/indicators

Functional positioning: Vacuum chamber top cover clamping+sealing combines mechanical clamping fixation and vacuum sealing to prevent chamber vacuum leakage

Compatible with core process chambers such as AMAT etching chambers (e.g. Etch Chamber) and PECVD deposition chambers, with a diameter of 300 mm/200 mm (mainstream specifications)

Sealing grade leakage rate ≤ 1 × 10 ⁻⁹ Pa · m ³/s meets the requirements of semiconductor processes for high vacuum environments (chamber working vacuum degree is usually 10 ⁻³~10 ⁻⁹ Pa)

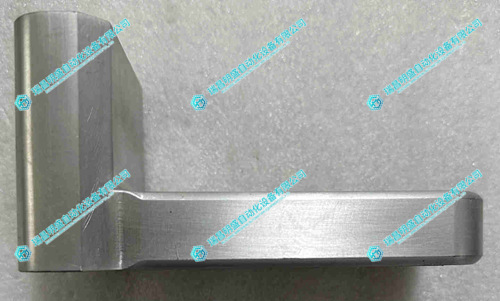

Sealing material: main sealing ring: perfluoroether rubber (FFKM); Auxiliary sealing: FKM FFKM is resistant to chemical corrosion (able to withstand plasma, acid and alkali process gases) and high temperature (long-term working temperature -20~200 ℃), avoiding seal failure caused by aging of the sealing ring

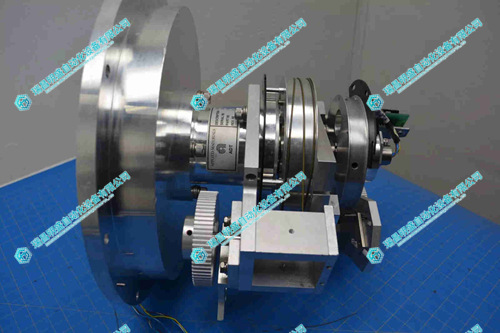

The clamping structure consists of a 4-point mechanical buckle and a pneumatic drive buckle made of stainless steel 316L material (corrosion-resistant). The buckle is opened and closed by a pneumatic cylinder, and the clamping force can be adjusted (rated clamping force 500~800 N) to ensure even force distribution on the top cover

Fully open/close time ≤ 15 seconds, in conjunction with equipment automation processes, to shorten downtime for chamber maintenance (such as component replacement, cleaning)

Working environment temperature -10~80 ℃; Resistant to plasma and process gas corrosion, suitable for highly corrosive and dusty process environments around the chamber. The surface of the components is passivated (such as electrolytic polishing) to reduce the adhesion of process residues

2、 Core components and functions

Mechanical buckle unit: 4 symmetrically distributed stainless steel buckles, which achieve the "buckle unlock" action through pneumatic drive, ensuring a tight fit between the top cover and the chamber flange, and avoiding displacement of the top cover under vacuum environment.

Sealing gasket component: The main sealing ring (FFKM) is embedded in the groove on the inner side of the clamp cover, tightly contacting the chamber flange surface to form a vacuum seal; The auxiliary sealing ring (FKM) is used to isolate external dust and water vapor, and protect the main sealing area.

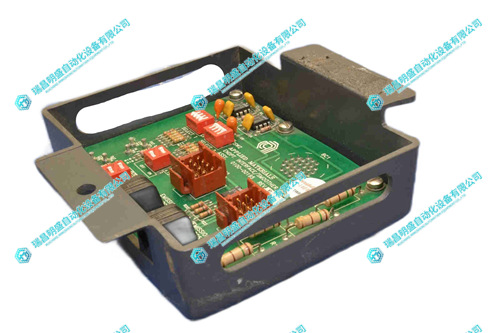

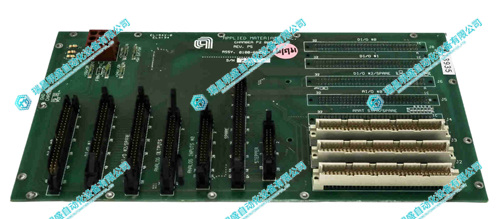

Pneumatic control module: includes a small pneumatic cylinder, solenoid valve, and pressure sensor, which can monitor the clamping pressure in real time (usually 0.4~0.6 MPa), trigger an alarm when the pressure is insufficient, and prevent seal failure.

AMAT Applied Materials 0021-07089夹盖组件 产品展示

产品视频

3.其他产品

GE IC697PWR711 电源模块

Socapel SOCASIN ST1/10-310 伺服放大器

ABB 2CSG299893R4052面板计量器

4.其他英文产品

PFEA112-20 3BSE030369R0020 Tension controller

FCP280 RH924YA control module

REM615 HCMJAEADABC2BNN11E Touch screen

| 710-566008-00 | 03-417236-00 | 720-06888-001 |

| 710-566006-00 | A90-031-03 | 710-658177-20 |

| 710-5000817-00 | 531X111PSHABG1 | F31X128HMSA |

| 710-451386-00 | 193X737AAG01 | 531X308PCSADG3 |

| 710-404778-00 | 03-169460-00N | F31X125SNHADG2 |

| 710-404576-00 | 6DD1684-0DK0 | 710-652840-20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218