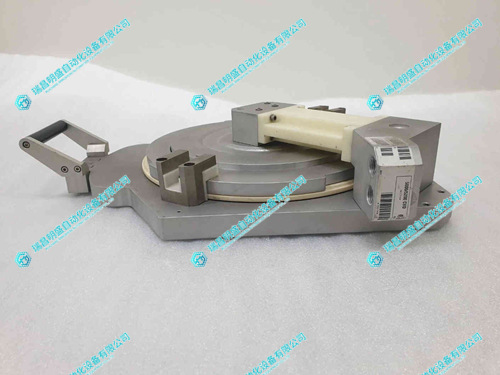

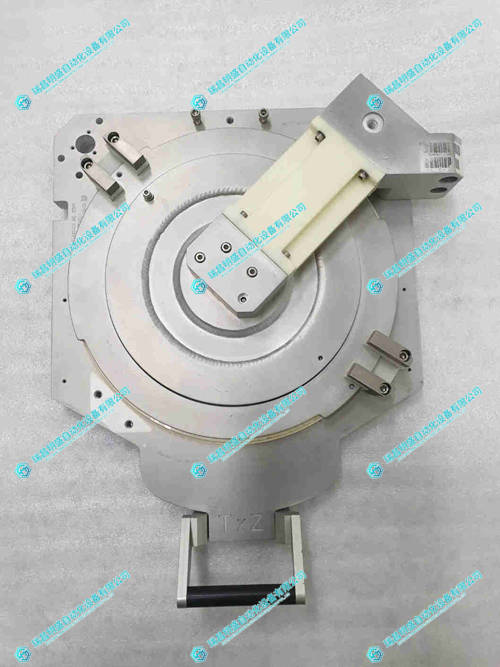

AMAT Applied Materials 0242-88626套件泵板

1.产 品 资 料 介 绍:

AMAT Applied Materials 0242-88626 套件泵板

一、核心规格与技术参数

二、核心组件与功能

AMAT Applied Materials 0242-88626套件泵板 英文资料:

AMAT Applied Materials 0242-88626 Kit Pump Plate

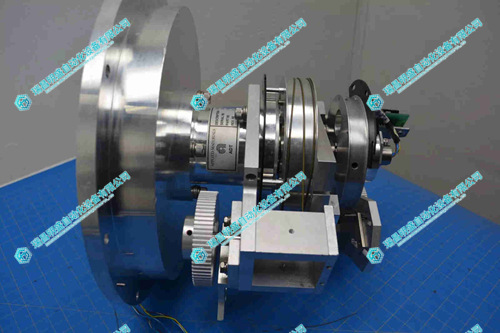

AMAT 0242-88626 is a vacuum pump integrated installation kit pump board designed specifically for semiconductor equipment vacuum systems. Its core function is to provide standardized installation bases, pipeline interfaces, and auxiliary accessory integration for vacuum pumps such as dry screw pumps and vortex pumps. It is compatible with process chamber vacuum exhaust systems on platforms such as Centura and Endura, ensuring a sealed connection, stable fixation, and efficient exhaust between the vacuum pump and chamber, while simplifying equipment assembly and maintenance processes.

1、 Core specifications and technical parameters

Detailed description of project specifications/indicators

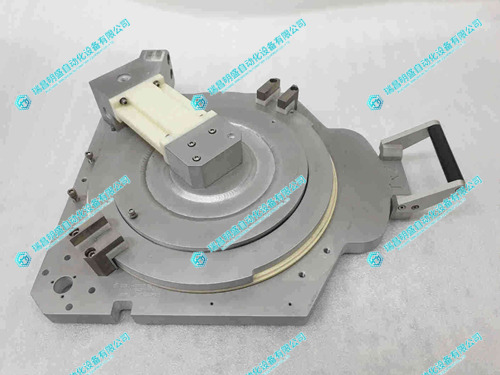

Functional positioning: Vacuum pump installation base+integrated pipeline interface+fixed accessories. The complete set of components includes vacuum pump installation bracket, vacuum pipeline flange, sealing gasket, fixing bolt, etc., without the need to purchase additional scattered accessories

Compatible with vacuum pump dry screw pump (≤ 150 m ³/h pumping speed), vortex pump (≤ 50 m ³/h pumping speed), AMAT original vacuum pump (such as PV600 series) and third-party vacuum pumps that comply with ISO vacuum flange standards

The installation size of the base is 600 × 400 mm (length × width), which is compatible with the standard vacuum pump base hole position. The installation hole distance can be adjusted by adjusting the gasket (± 5 mm), and is compatible with the installation size differences of different brands of vacuum pumps

Vacuum interface main interface: ISO-K 63 (vacuum sealed flange); Auxiliary interface: ISO-K 25 (pressure detection interface) The main interface is used to connect the chamber exhaust pipeline, and the auxiliary interface can be connected to a vacuum gauge (such as Pirani gauge) to monitor the exhaust pressure. The flange sealing surface is electrolytic polished (Ra ≤ 0.8 μ m) to reduce the risk of air leakage

Material and anti-corrosion base: Stainless steel 304 (thickness 10mm, load-bearing capacity ≤ 500 kg); Sealing element: Perfluoroether rubber (FFKM) stainless steel base is resistant to process gas corrosion (such as fluorinated tail gas after etching), FFKM sealing element can withstand high temperature of 200 ℃ and strong corrosive gases, avoiding aging and leakage

The accessories include fixing bolts (M12 × 50 mm, stainless steel 316L), shock-absorbing gaskets (silicone material, thickness 5 mm), vacuum seal O-rings (FFKM, diameter 63 mm), and installation locating pins. The shock-absorbing gaskets can absorb the vibration of the vacuum pump during operation and reduce the impact on the chamber and other components of the equipment

2、 Core components and functions

Load bearing installation base: A rigid base made of stainless steel material that can stably carry the weight of the vacuum pump (≤ 500 kg). The bottom of the base is reserved with fixing holes that can be connected to equipment racks or ground bolts to prevent displacement of the vacuum pump during operation.

Vacuum pipeline interface: ISO-K standard flange interface, connected to the chamber exhaust pipeline through FFKM sealing O-ring, ensuring vacuum sealing level (leakage rate ≤ 1 × 10 ⁻⁸ Pa · m ³/s), meeting the high vacuum requirements of the process chamber.

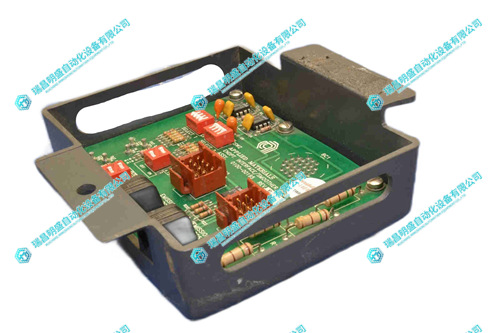

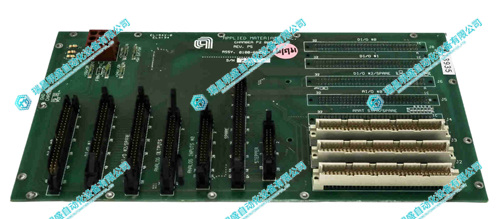

AMAT Applied Materials 0242-88626套件泵板 产品展示

产品视频

3.其他产品

GE IC697PWR711 电源模块

Socapel SOCASIN ST1/10-310 伺服放大器

ABB 2CSG299893R4052面板计量器

4.其他英文产品

PFEA112-20 3BSE030369R0020 Tension controller

FCP280 RH924YA control module

REM615 HCMJAEADABC2BNN11E Touch screen

| 710-566008-00 | 03-417236-00 | 720-06888-001 |

| 710-566006-00 | A90-031-03 | 710-658177-20 |

| 710-5000817-00 | 531X111PSHABG1 | F31X128HMSA |

| 710-451386-00 | 193X737AAG01 | 531X308PCSADG3 |

| 710-404778-00 | 03-169460-00N | F31X125SNHADG2 |

| 710-404576-00 | 6DD1684-0DK0 | 710-652840-20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218