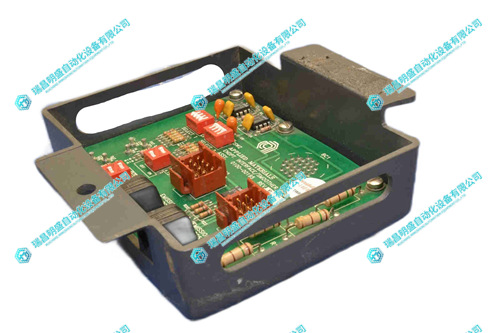

AMAT Applied Materials 9090-00115监视器机箱

1.产 品 资 料 介 绍:

AMAT Applied Materials 9090-00115 监视器机箱

一、核心规格与技术参数

二、核心功能与设计优势

AMAT Applied Materials 9090-00115监视器机箱 英文资料:

AMAT Applied Materials 9090-00115 Monitor Case

AMAT 9090-00115 is an industrial grade monitor integrated chassis designed specifically for semiconductor equipment human-machine interaction (HMI). Its core function is to provide standardized installation carriers and protective enclosures for display screens, operation buttons, indicator lights, and control modules. It is compatible with equipment operation panels of wafer process platforms such as Centura and Endura, ensuring stable operation in high cleanliness and multi interference semiconductor workshop environments while meeting the convenience and safety of human-machine interaction.

1、 Core specifications and technical parameters

Detailed description of project specifications/indicators

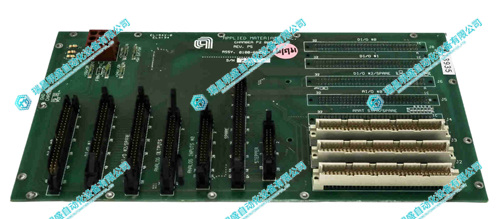

Function positioning monitor installation+operation control integration+module protection integration display screen installation position, button/indicator light interface, internal control module fixing bracket, achieving "display operation control" integration

Compatible with 10.4-inch/12.1-inch industrial touch screens (4:3 ratio) compatible with AMAT original industrial screens or third-party displays that comply with VESA standards (75 × 75mm/100 × 100mm)

Material and protective shell: 304 stainless steel (thickness 1.5mm); Protection level: IP54 304 stainless steel resistant to weak corrosive gases commonly found in semiconductor workshops (such as isopropanol volatile gas for cleaning), IP54 dustproof and splash proof liquid, suitable for workshop cleaning and maintenance scenarios

The internal installation space has an internal depth of 150mm and can accommodate 2 standard 35mm rail modules. It can install auxiliary control components such as I/O modules and communication modules (such as RS485 converters) without the need for additional independent control cabinets

Front interface configuration: 1 USB 2.0 interface (for screen calibration/data export); Side: 2 DB9 serial ports (RS232), 1 Ethernet network port interface with waterproof and dustproof cover, closed when not in use to prevent dust or liquid from entering; Support communication connection with the main controller of the device

The top and bottom louvers of the heat dissipation design are ventilated, and the internal heat dissipation ribs are naturally ventilated to avoid dust accumulation and noise caused by the fan. At the same time, the heat conduction is enhanced through the heat dissipation ribs to ensure that the working temperature of the internal module is ≤ 55 ℃

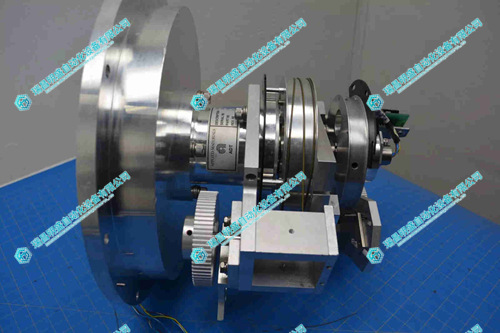

Installation method: Cantilever installation (compatible with AMAT standard cantilever bracket)/Panel embedded installation. Cantilever can flexibly adjust the operating angle (0-90 ° tilt), and the embedded adaptation equipment console panel has holes (hole size: 285 × 220mm/310 × 245mm, depending on the screen size)

Working environment temperature 0-60 ℃; Humidity ≤ 85% RH (no condensation); Anti electromagnetic interference: EN 61000-6-2 standard can withstand temperature and humidity fluctuations in semiconductor workshops, resist electromagnetic interference during equipment operation (such as interference generated by motors and frequency converters), and ensure stable operation of display screens and control modules

AMAT Applied Materials 9090-00115监视器机箱 产品展示

产品视频

3.其他产品

ProSoft 5205-DFNT-PDPS 以太网网关

Bently 3500/64M 176449-05 压力监测模块

ABB UFC760BE142 3BHE004573R0142 处理器模块

4.其他英文产品

GE IC693PWR322F Industrial control card

PFSK142 3BSE006505R1 Control system card

PM891 3BSE053240R1 conversion module

| 6ES5998-1MF23 | 6DD1684-0BD0 | F31X139APMAJG2 |

| 6ES5998-1DL31 | 531X111PSHSWG2 | 531X308PCSADG2 |

| 6ES5998-1DB11 | 531X116SHAAAG2 | 208-500103-3 |

| 6ES5998-0UK31 | 531X121PCRAGG1 | 720-11200-002 |

| 6ES5998-0UF33 | 531X111PSHAPG1 | 820-30004-00 |

| 6ES5998-0SH21 | 193X804ADG02 | 710-655005-00 |

| 6ES5998-0MA34 | 531X113PSFASG1 | 710-659465-20 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218