AMAT Applied Materials 0010-09198安瓿组装

1.产 品 资 料 介 绍:

- 先进光刻工艺:储存光刻胶辅助气体(如有机金属化合物气体),通过精准释放控制光刻胶涂覆均匀性,保障光刻图案精度

- 原子层沉积(ALD):为 ALD 工艺提供高纯度金属源气体(如 TiCl₄、HfCl₄),实现薄膜的单原子层级沉积,控制膜厚精度

- 等离子体刻蚀:储存高选择性刻蚀气体(如 CF₄ 与 O₂ 混合气体),避免气体在输送过程中与空气反应,保障刻蚀图形侧壁垂直度

AMAT Applied Materials 0010-09198安瓿组装 英文资料:

1、 Product core positioning

AMAT 0010-09198 Ampoule Assembly is a sealed gas storage and release component designed by Applied Materials for the transportation of special gases in high-end semiconductor processes. It is a core component of the "high-precision gas supply unit" in semiconductor processes. Its core function is to store high-purity specialty gases (such as rare metal organic compounds and highly corrosive gases) required for photolithography, etching, and other processes in an ultra clean and highly sealed environment. Through precise rupture or opening mechanisms, it achieves quantitative and impurity free gas release, providing a stable and pure gas source for the process. It is a key component to ensure the precision and wafer yield of advanced processes (such as 7nm and below).

Unlike general industrial ampoules, this assembly uses semiconductor grade corrosion-resistant materials and ultra clean sealing technology, which can avoid pollution caused by gas contact with the outside world, and can withstand high pressure (or negative pressure) environments. It is suitable for Class 1 cleanliness requirements in semiconductor cleanrooms and has a safety design that prevents leakage and misoperation.

2、 Core structure and technical parameters (derived based on the general standard for semiconductor ampoules)

Based on the technical specifications of AMAT gas delivery system and the characteristics of semiconductor special gas ampoules, the core assembly specifications are speculated as follows:

Parameter category

Specification Description

Main structure and materials

The ampoule body is made of borosilicate glass (or Hastelloy alloy, depending on the gas type), with a wall thickness of 1.2-2.0mm; it is equipped with stainless steel 316L valve components, and the sealing interface adopts VCR standard

Sealing and Cleanliness

Initial sealing vacuum degree ≤ 1 × 10 ⁻⁸ Torr, internal particle size controlled at ≥ 0.1 μ m particles ≤ 1/cc; gas purity adapted to ≥ 99.99999% (7N level) special gas requirements

Capacity and operational characteristics

Effective volume of 5-50mL (depending on process requirements), opening method is mechanical puncture (or electric rupture), and the opening pressure is controlled at 0.3-0.8MPa

Environment and compatibility characteristics

Working temperature -40-80 ℃, withstand temperature fluctuations ± 5 ℃/h; compatible with corrosive/flammable and explosive gases such as HF, Cl ₂, SiH ₄, etc., with corrosion resistance level in accordance with ISO 10289 standard

Security and Certification

Integrated overpressure protection valve (burst pressure 1.5 times rated working pressure); Compliant with SEMI G13 gas safety standards and RoHS environmental certification

3、 Application scenarios and adaptation systems

1. Core application areas

As a "clean storage carrier" for specialty gases, this ampoule assembly mainly serves the extremely high gas purity requirements in semiconductor processes:

Advanced photolithography process: Store photoresist auxiliary gases (such as organic metal compound gases), control the uniformity of photoresist coating through precise release, and ensure the accuracy of photolithography patterns

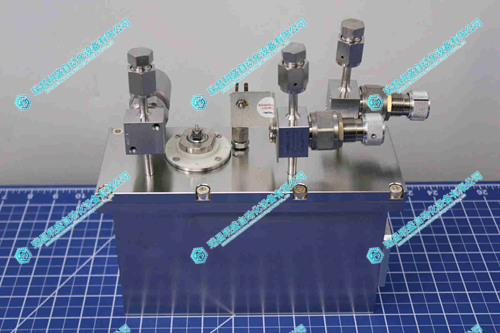

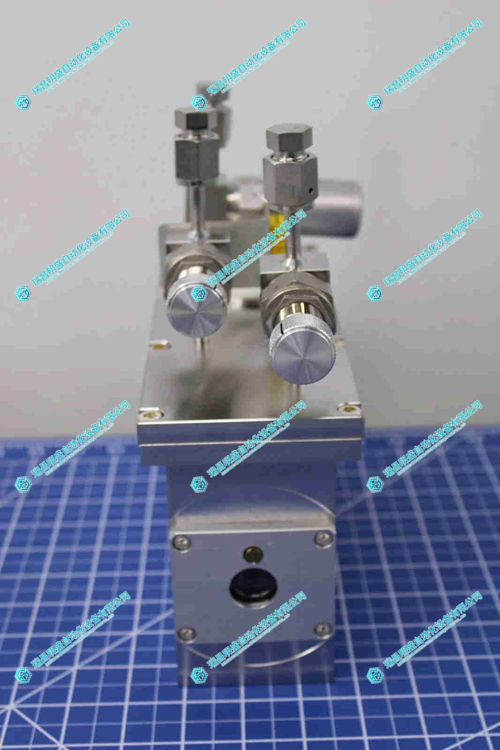

AMAT Applied Materials 0010-09198安瓿组装 产品展示

产品视频

3.其他产品

CCC MCP-1004 交流电电源单元

YOKOGAWA SDV144-S63 数字输入模块

A-B 22A-A2P3N114 交流电驱动器

4.其他英文产品

PFTL101A 1.0KN 3BSE004166R1 Tension sensor

07KT97 GJR5253000R4270 module

07KT98 GJR5253100R4278 Logic module

| 6ES5998-2DB31 | 193X741ABG03 | 710-302183-00 |

| 6ES5998-1UD31 | 531X111PSHARG3 | 500-225578-000 |

| 6ES5998-1MF23 | 6DD1684-0BD0 | F31X139APMAJG2 |

| 6ES5998-1DL31 | 531X111PSHSWG2 | 531X308PCSADG2 |

| 6ES5998-1DB11 | 531X116SHAAAG2 | 208-500103-3 |

| 6ES5998-0UK31 | 531X121PCRAGG1 | 720-11200-002 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218