AMAT Applied Materials AS01391-23接口模块

1.产 品 资 料 介 绍:

- 工业级通信接口全覆盖

- 高速网络接口:2 个千兆以太网口(支持 Profinet、EtherNet/IP 协议),传输速率达 1000Mbps,数据传输延迟≤5ms,可实现设备主控制器与工厂 MES 系统的高速数据交互,支持工艺参数实时上传与远程控制指令下发;

- 现场总线接口:3 个 RS485 串口(通信速率 0-2Mbps 可调)、1 个 CANopen 总线接口,适配传感器集群(如温度、压力传感器)、执行器(伺服电机驱动器、电磁阀)的连接需求,支持多节点级联(RS485 最多可连接 32 个节点),满足设备分布式控制场景;

- 专用功能接口:1 个 USB 2.0 接口(用于本地参数配置与日志导出)、1 个光纤接口(传输距离≤5km,抗干扰能力强),适配洁净车间远距离设备布局与本地运维操作,兼顾数据传输稳定性与操作便捷性。

- 信号转换与适配能力

- 能将温度、压力等传感器输出的 mV 级微弱模拟信号放大并转换为数字信号,传输至控制器,信号转换精度达 ±0.1% F.S.;

- 可将控制器下发的数字控制指令转换为模拟信号,驱动阀门、电机等执行机构,无需额外信号转换模块,简化设备布线与集成流程,降低信号传输损耗。

- 协议自适应与灵活配置

AMAT Applied Materials AS01391-23接口模块 英文资料:

1、 Multi scenario interface compatibility: building a bridge for semiconductor device interconnection

As the "connection hub" for various functional modules of semiconductor equipment, the AS01391-23 interface module covers all types of interfaces as its core, breaking down communication barriers between different devices and modules and achieving seamless flow of data and signals

Industrial grade communication interface full coverage

Mainstream communication interfaces commonly used in integrated semiconductor equipment to meet multi-dimensional interconnection requirements:

High speed network interface: 2 Gigabit Ethernet ports (supporting Profinet and EtherNet/IP protocols), with a transmission rate of 1000Mbps and a data transmission delay of ≤ 5ms, capable of high-speed data exchange between the equipment main controller and the factory MES system, supporting real-time uploading of process parameters and remote control command issuance;

Fieldbus interface: 3 RS485 serial ports (communication rate adjustable from 0-2Mbps), 1 CANopen bus interface, adapted to the connection requirements of sensor clusters (such as temperature and pressure sensors) and actuators (servo motor drivers, solenoid valves), supporting multi node cascading (RS485 can connect up to 32 nodes), meeting the requirements of distributed control scenarios for devices;

Special functional interfaces: 1 USB 2.0 interface (for local parameter configuration and log export), 1 fiber optic interface (transmission distance ≤ 5km, strong anti-interference ability), suitable for long-distance equipment layout and local operation and maintenance in clean workshops, balancing data transmission stability and operational convenience.

Signal conversion and adaptation capability

Equipped with bidirectional conversion between analog and digital signals, with 6 analog input/output interfaces (supporting 4-20mA current signals and 0-10V voltage signals) and 12 digital input/output interfaces (compatible with TTL/CMOS levels), it can directly interface with different types of sensors and actuators:

Capable of amplifying and converting mV level weak analog signals output by temperature, pressure, and other sensors into digital signals, which are transmitted to the controller with a signal conversion accuracy of ± 0.1% F.S;

The digital control instructions issued by the controller can be converted into analog signals to drive actuators such as valves and motors without the need for additional signal conversion modules, simplifying equipment wiring and integration processes and reducing signal transmission losses.

Protocol adaptation and flexible configuration

Built in intelligent protocol recognition chip, supporting automatic matching of communication protocols for access devices (such as Profinet, Modbus RTU/TCP), without the need for manual configuration of protocol parameters. Protocol negotiation can be automatically completed when connecting new devices, with an adaptation cycle of ≤ 30 minutes; For third-party devices with non-standard protocols (such as special sensors), support customizing protocol frame formats (including data bits, parity bits, and stop bits) through onboard configuration software to achieve compatible communication with the device's main system, greatly improving device integration flexibility.

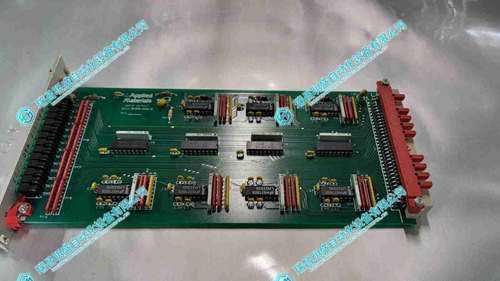

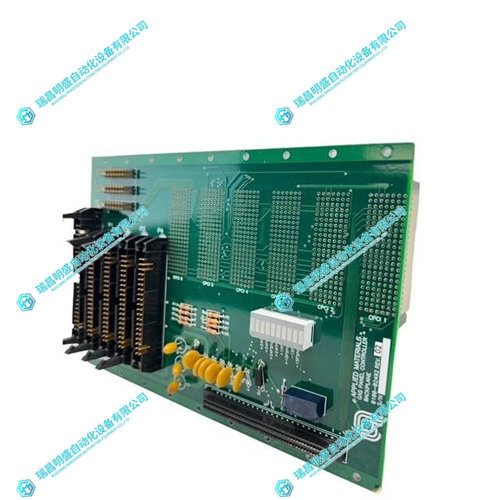

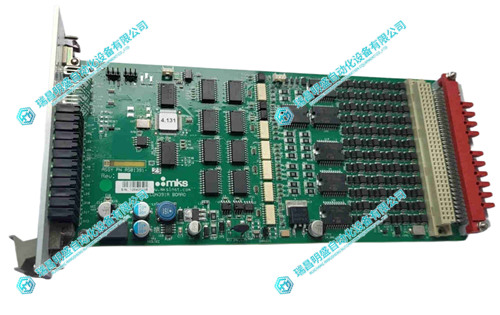

AMAT Applied Materials AS01391-23接口模块 产品展示

产品视频

3.其他产品

KJ3222X1-BA1模拟输入模块

VE5010 输入模块

CI871AK01 3BSE092693R1 接口模块

4.其他英文产品

HIMA K9203A Fan components

Rexroth MHD041B-144-PG1-UN Servo motor

PM864AK01 3BSE018161R1 Control processor

| 6ES5721-0BB00 | CACR-SR15BB1CSY8 | 61-0367-37 |

| 6ES5714-3CF00 | CACR-SR05BA1AM | 148472-006 |

| 6ES5714-3CB00 | CACR-SR15SZ1SSY228 | C2SBI-RSYS-JD1 |

| 6ES5712-8BF00 | CACR-HR10UB-Y9 | EMC-BP12 |

| 6ES5710-8MA21 | CACR-SV3AAA | 288-8059-300 |

| 6ES5707-1AA00 | CACR-SR03BE12G-E | 61-0626-00 |

| 6ES5706-5BF00 | CACR-SR03SB1BFY199 | P1366BX-SVE |

| 6ES5706-3BF00 | CACR-IR01SFB | 061-01771-0051 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218