Magnetek CIMR-G5M41P5矢量起重机控制器

1.产 品 资 料 介 绍:

- 专为起重工况优化的矢量控制:运用闭环或开环磁通矢量控制技术,能实现高精度的起升与行走控制;在低速状态下,可保持强劲扭矩,避免重载时出现打滑或漂移现象。

- 四象限运行支持:可支持起升、下降以及正反转制动控制,能适配再生制动模块,从而实现能量回馈或高效制动。

- 抗晃动功能(Anti-Sway):可以选配防晃控制逻辑模块,适用于桥吊、抓斗等场景,能有效减轻载荷晃动,提高吊运效率和安全性。

- 快速响应制动逻辑:内置制动控制曲线设定,支持断电快速停机与刹车协同控制,增强人员和设备的安全性。

- 多种安全保护机制:涵盖制动器确认逻辑、编码器故障检测、电机堵转检测、制动失败告警等,符合 EN、ANSI 标准下的工业安全要求。

- 自学习电机参数调校:启动前可自动识别电机参数,有助于提高驱动控制的精度和效率,尤其适用于替换原设备电机或进行设备改造的场景。

- 起重设备专用功能参数组:设定界面专门针对起升、横移、纵移三种典型驱动方式设计,参数分类清晰,方便调试操作。

英文资料:

MAGNETEK CIMR-G5M41P5 belongs to the Magnetek G5 series and is a vector controlled variable frequency drive/controller specifically designed for lifting equipment. It has high reliability and responsiveness, and has optimized motion control performance for lifting conditions.

Core product features

Vector control optimized for lifting conditions: using closed-loop or open-loop magnetic flux vector control technology, high-precision lifting and walking control can be achieved; At low speeds, it can maintain strong torque and avoid slipping or drifting during heavy loads.

Four quadrant operation support: It can support lifting, lowering, and forward/reverse braking control, and can be adapted to regenerative braking modules to achieve energy feedback or efficient braking.

Anti sway function: An anti sway control logic module can be optionally selected, suitable for scenarios such as bridge cranes and grab buckets, which can effectively reduce load sway, improve lifting efficiency and safety.

Quick response braking logic: Built in braking control curve setting, supporting power-off rapid shutdown and coordinated braking control, enhancing the safety of personnel and equipment.

Multiple safety protection mechanisms: covering brake confirmation logic, encoder fault detection, motor stall detection, brake failure alarm, etc., in compliance with industrial safety requirements under EN and ANSI standards.

Self learning motor parameter tuning: Before starting, the motor parameters can be automatically identified, which helps improve the accuracy and efficiency of drive control, especially suitable for scenarios where the original equipment motor is replaced or equipment is modified.

Special functional parameter group for lifting equipment: The setting interface is specifically designed for three typical driving modes: lifting, lateral movement, and longitudinal movement. The parameter classification is clear and easy to debug and operate.

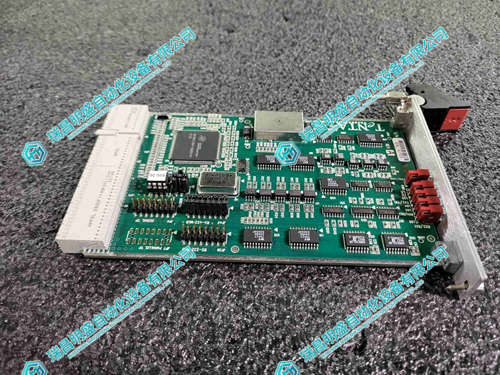

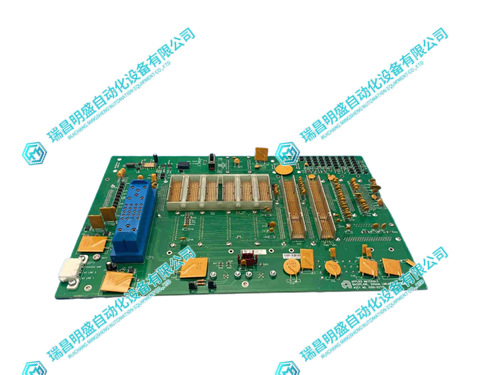

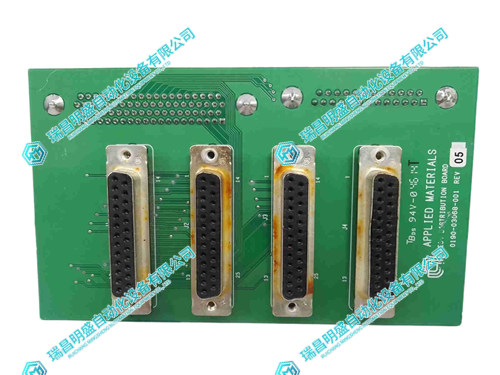

2.产 品 展 示

3.其他产品

4.其他英文产品

IS200EPSMG1ABB Analog Input Module

AMAT 0190-24282 encoder module

AMAT 0190-11415 Digital Input Module

| 6ES5895-5SW01 | CACR-SR20SZ1SFY91 | 61-0881-10 |

| 6ES5895-3ST21 | CACR-PR07BC3BM | 61-0669-02 |

| 6ES5895-3SF55 | CACR-SR15BE | 68-0059-12 |

| 6ES5895-0BS22 | CACR-180-PD1VDS03 | 061-01183-0031 |

| 6ES58941MA040UD3 | CACR-SR05SB1BFY187 | 504802-008 |

| 6ES58940MA040UG6 | CACR-SR-20SB1BFY118 | UIMC-III-1 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218