1.产 品 资 料 介 绍:

CFCFPS - A0076 控制器升降站产品特点(15 条,纯文本无链接)

CFCFPS-A0076控制器升降站 英文资料:

CFCFPS-A0076 Controller Lift Station Product Features (15 items, text without links)

Integrated lifting drive control and central signal processing function, suitable for the vertical lifting control requirements of materials/equipment in industrial automation production lines, warehousing logistics and other scenarios.

Equipped with high-performance embedded controller, supporting multi axis synchronous control, the lifting positioning accuracy can reach ± 0.5mm, suitable for high-precision material docking and assembly operations.

Supports PWM closed-loop speed regulation, with adjustable lifting speed of 0.1-10mm/min, and can flexibly switch operating parameters according to load weight and work rhythm.

Compatible with EtherNet/IP and Profinet field bus protocols, it can communicate seamlessly with PLC, HMI and upper computer to realize remote monitoring and centralized dispatching.

Built in multiple safety protection mechanisms, including overload protection, overspeed protection, upper and lower limit protection, and emergency stop interlock, ensure the safety and reliability of the lifting process.

Equipped with a high-definition LCD touch control screen, supporting functions such as parameter setting, status display, and fault alarm, the operation is intuitive and convenient, reducing the threshold for manual operation.

The drive unit is compatible with AC380V three-phase power supply, with output power ranging from 0.75kW to 15kW, and can drive various lifting actuators such as screw, chain, and hydraulic.

Equipped with power-off memory function, it can save the current position and operating parameters, automatically restore the operating state after power supply is restored, and avoid job interruption.

Support multi-mode operation control, including automatic positioning, manual fine-tuning, jog control, etc., adapted to the control requirements of different job processes.

Built in fault diagnosis module, which can monitor the status of components such as motors, drivers, and sensors in real time, and quickly locate problems through sound and light alarms and fault codes.

Working temperature range -20 ℃~+60 ℃, relative humidity 5%~95%, no condensation, protection level IP40, suitable for complex indoor and outdoor industrial environments.

Adopting modular design, the core control unit, drive unit, and operation unit can be independently disassembled and maintained, reducing maintenance difficulty and downtime.

Support external sensor access, such as displacement sensors, pressure sensors, etc., to achieve closed-loop feedback control and improve the stability and accuracy of the lifting process.

It has the function of hierarchical management of permissions, which can set different permissions for administrators, operators, etc., to prevent unauthorized personnel from tampering with key operating parameters.

Compliant with ISO 13849-1 functional safety standards, certified by CE and UL, suitable for global industrial application scenarios, ensuring equipment compliance and reliability.

Summary: The CFCFPS-A0076 controller lifting station has the core advantages of high-precision control, multi protocol compatibility, and multiple safety protections. It combines flexibility and stability, making it an ideal choice for industrial lifting automation upgrades, which can effectively improve production efficiency and operational safety.

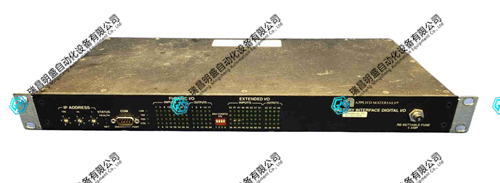

CFCFPS-A0076控制器升降站 产品展示

产品视频

3.其他产品

ABB HC800控制处理器模块

ABB PM866K01 3BSE050198R1控制器

BENTLY 3500/42M 176449-02卡件

4.其他英文产品

MVME2100 controller card

PFSK152 3BSE018877R1 pulse output card

PP877K 3BSE069274R1 Touch screen

| PMB31D-00116-01 | 07KT60R101 | PFCL201 50.0KN |

| PMB31D-00116-00 | PHCBRCPBA10000 | 3BSE004253R1 SX540 |

| PMB31D-00114-03 | AMAT 0130-20335 | M22NRXB-LNN-NS-02 |

| PMB31D-00114-02 | 07BV60R1 | 57160001-LF DSTD 133 |

| PMB31D-00114-01 | 70 AS 06a-E | PWM3636-5486-7 |

| PMB31D-00114-00 | 70 FV 01a-E | 57160001-FH DSTD 170 |

| PMB31D-00101-03 | 07NG63R2 | N42HRFM-LNK-NS-00 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218