1.产 品 资 料 介 绍:

18-21-13237处理器模块 英文资料:

Equipped with multi-core high-performance processors, the clock speed can reach 2.5GHz, and the single module computing power supports tens of millions of instructions per second, adapting to the complex logic control and data processing needs of industrial automation.

Integrated large capacity high-speed cache and local storage, cache capacity ≥ 4MB, local storage supports 16GB-64GB expandable, ensuring fast instruction reading and real-time data caching.

Supports multi protocol parallel communication, compatible with mainstream industrial buses such as EtherNet/IP, Profinet, Modbus TCP, etc., with a maximum data transmission rate of up to 1000Mbps, meeting high-speed networking requirements.

Built in hardware level security encryption module, supporting AES-256 encryption algorithm, can encrypt program code and transmission data, preventing unauthorized access and data tampering.

Equipped with a multitasking real-time operating system, supporting task priority scheduling, response time ≤ 1ms, suitable for industrial scenarios with high real-time requirements such as motion control and process control.

Supports hot redundancy and dual machine hot backup functions, with automatic data synchronization between the main and backup modules, and a fault switching time of less than 50ms, ensuring continuous and stable system operation and reducing downtime risks.

Integrate rich peripheral interfaces, including high-speed digital I/O, SPI, I ² C, CAN, etc., which can directly interface with sensors, actuators, and expansion modules to enhance system integration flexibility.

Built in precise clock synchronization function, supporting IEEE 1588 PTP protocol, clock synchronization accuracy can reach nanosecond level, suitable for timing requirements of multi device collaborative control.

Having comprehensive fault diagnosis capabilities, it can monitor CPU, memory, communication interfaces, and power supply status in real time, and provide fault information feedback through indicator lights and messages, making it easy to quickly locate problems.

Working temperature range -40 ℃~+85 ℃, relative humidity 5% -95%, no condensation, protection level IP30, can operate stably in harsh industrial environments such as dust and vibration.

Adopting a fanless cooling design, coupled with efficient heat sinks, it can maintain low temperature even under full load operation, extend the service life of core components, and reduce maintenance costs.

Support online programming and remote firmware upgrades, program updates can be completed without disassembling modules, adapting to the non-stop maintenance needs of production lines.

Adopting a guide rail installation with a width of only 35mm, it can be tightly arranged with I/O modules and communication modules, effectively saving control cabinet space and simplifying wiring.

Support data log storage function, which can record key operating parameters and fault information, with a storage time of up to 30 days, providing data support for fault tracing and system optimization.

Compliant with the IEC 61131-3 programming standard, compatible with multiple programming languages such as LD, FBD, ST, etc., adapting to the programming habits of different engineers and reducing development difficulty.

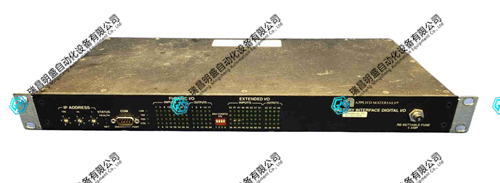

18-21-13237处理器模块 产品展示

产品视频

3.其他产品

ABB PM866K01 3BSE050198R1控制器

BENTLY 3500/42M 176449-02卡件

DANAHER S21260-SRS伺服驱动器

4.其他英文产品

PP877K 3BSE069274R1 Touch screen

PPC907BE 3BHE024577R0101 processor input module

PPE091A101 3BHE044481R0101 Control module

| PMB31B-20216-03 | 70 FA 01b | 3ASD573001A13 YPK112A |

| PMB31B-20216-02 | IIMCL01 | 57120001-KH DSTA 156 |

| PMB31B-20216-01 | 70 BL 02C | R32GENC-TS-NS-VS-00 |

| PMB31B-20216-00 | AMAT 0100-09136 | 57160001-P DSTD 120 |

| PMB31B-20214-03 | 07YS81 | R32HSNG-TS-NS-NV-02 |

| PMB31B-20214-02 | Amat 0100-02839 | 57160001-TK DSDI 141A |

| PMB31B-20214-01 | PHAREPRFO10000 | 57160001-DV DSDP 110 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218