AMAT Applied Materials 0190-09445 检测器

1.产 品 资 料 介 绍:

- 射频系统状态监测:安装于 AMAT 0041-78374 射频匹配组件与反应腔之间的射频通路,实时检测射频反射功率。当反射功率超出阈值(如>5W)时,立即向控制器发送报警信号,触发匹配组件重新调节阻抗,避免反射功率过高损坏射频电源或影响等离子体稳定性。

- 等离子体工艺监测:通过蓝宝石窗口对准反应腔内部等离子体区域,采集等离子体光强信号(如刻蚀工艺中 CF₄ 等离子体的 703nm 特征光谱)。控制器通过光强变化分析等离子体密度,动态调整射频功率、气体流量等参数,保障刻蚀速率、薄膜沉积质量的一致性。

- 腔室环境安全监测:在反应腔维护过程中,监测腔室内残留等离子体光强,当光强降至安全阈值(<1μW/cm²)以下时,允许维护人员开启腔室,防止残留等离子体对人员造成伤害;同时监测腔室壁面温度(通过内置温度传感元件),避免温度过高导致腔室部件老化。

- 设备故障预警:长期监测射频功率波动与等离子体光强稳定性,通过数据趋势分析提前预判潜在故障(如射频线缆老化、匹配组件电容性能衰减),触发预防性维护提醒,减少非计划停机时间。

- 主机设备适配:广泛应用于 AMAT Centura 刻蚀系统、Endura 沉积平台、Producer 薄膜沉积设备及离子注入机等依赖射频与等离子体工艺的半导体设备。

- 配套模块兼容:与 AMAT 0190 系列射频组件、0225 系列控制器、0100 系列电子接口模块及第三方数据采集系统(如 NI cDAQ 系列)直接对接,形成 “检测 - 信号传输 - 分析 - 控制” 的闭环监测体系。

- 协同组件联动:可与设备健康管理系统(PHM)联动,将实时检测数据与历史数据对比,通过算法识别异常模式(如射频功率波动频率增加),自动生成故障诊断报告,辅助运维人员精准定位问题。

- 安装前准备:确认安装区域洁净度符合 Class 10 标准,用异丙醇(99.999% 纯度)清洁检测器表面及法兰接口;检查检测器外观无损伤、蓝宝石窗口无划痕,接线端子无氧化;准备专用屏蔽线缆(模拟信号线为双绞屏蔽线,数字信号线为 RS-485 专用线缆)、扭矩扳手(精度 ±5%)及真空密封胶(如 Loctite 577)。

- 硬件安装:按设备图纸将检测器通过法兰固定在反应腔或射频通路指定位置,确保蓝宝石窗口正对监测目标(等离子体区域或射频线缆接头);法兰密封面涂抹真空密封胶,扭矩控制在 15-20N・m,确保真空密封等级≥10⁻⁵ Torr;连接供电线与信号线,屏蔽层单端接地(接地电阻≤0.5Ω),避免与射频线缆平行敷设。

- 调试与验证:接入设备控制系统后,进行 “零点校准” 与 “量程校准”:射频检测端接入标准功率源(如 100W、300W、500W),校准输出信号与标准值的偏差;光强检测端用标准光源(已知光强 10-1000μW/cm²)校准,确保检测精度 ±2% FS 内;设定报警阈值(如射频反射功率>5W、光强波动>10%/min),测试报警功能是否正常触发。

AMAT Applied Materials 0190-09445 检测器 英文资料:

Application scenarios and adaptation systems

1. Core application areas

As a "precision monitoring eye" for device status, this detector mainly serves the key links in semiconductor manufacturing that require real-time monitoring of multiple parameters:

RF system status monitoring: Installed in the RF path between the AMAT 0041-78374 RF matching component and the reaction chamber, real-time detection of RF reflected power. When the reflected power exceeds the threshold (such as>5W), an alarm signal is immediately sent to the controller to trigger the matching component to readjust the impedance, avoiding damage to the RF power supply or plasma stability caused by excessive reflected power.

Plasma process monitoring: Align the plasma area inside the reaction chamber through a sapphire window and collect plasma intensity signals (such as the 703nm characteristic spectrum of CF ₄ plasma in etching process). The controller analyzes the plasma density through changes in light intensity, dynamically adjusts parameters such as RF power and gas flow rate, and ensures consistency in etching rate and thin film deposition quality.

Chamber environment safety monitoring: During the maintenance process of the reaction chamber, the residual plasma intensity inside the chamber is monitored. When the intensity drops below the safety threshold (<1 μ W/cm ²), maintenance personnel are allowed to open the chamber to prevent residual plasma from causing harm to personnel; Simultaneously monitor the temperature of the chamber wall (through built-in temperature sensing elements) to avoid excessive temperature that may cause aging of chamber components.

Equipment fault warning: Long term monitoring of RF power fluctuations and plasma intensity stability, predicting potential faults in advance through data trend analysis (such as RF cable aging, matching component capacitance performance degradation), triggering preventive maintenance reminders, and reducing unplanned downtime.

2. Adapt devices and systems

Host device adaptation: widely used in semiconductor devices such as AMAT Centura etching system, Endura deposition platform, Producer thin film deposition equipment, and ion implantation machines that rely on RF and plasma processes.

Compatibility with supporting modules: Directly interface with AMAT 0190 series RF components, 0225 series controllers, 0100 series electronic interface modules, and third-party data acquisition systems (such as NI cDAQ series) to form a closed-loop monitoring system of "detection signal transmission analysis control".

Collaborative component linkage: It can be linked with the Device Health Management System (PHM) to compare real-time detection data with historical data, identify abnormal patterns (such as increased RF power fluctuation frequency) through algorithms, automatically generate fault diagnosis reports, and assist operation and maintenance personnel in accurately locating problems.

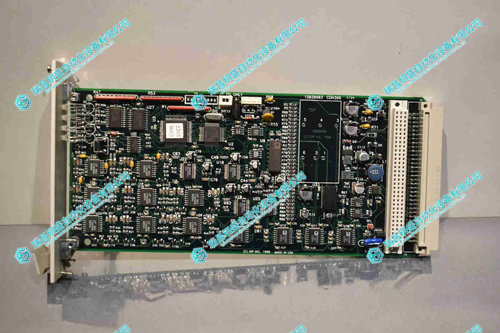

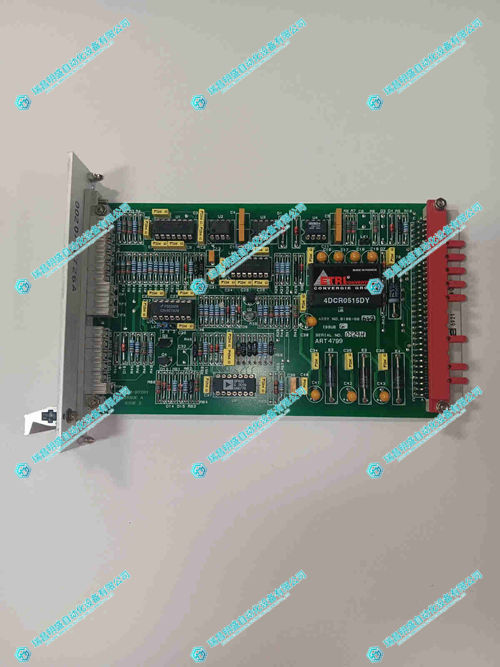

AMAT Applied Materials 0190-09445 检测器 产品展示

产品视频

3.其他产品

ROLLS-ROYCE 5801-RRDIO15 WB I/O 警报模块

NI CRI0-9073 控制器模块

A-B 1326AS-B440G-21 电动伺服电机

4.其他英文产品

METSO IOP304 Sequential module

METSO IOP320 Sequential module

METSO IOP331 Servo module

| 6ES5897-2PF11 | CACR-W37-FJ3ER | 44373702 |

| 6ES5897-2KB21 | CACR-SR-10SZ1SFY221 | EXM22 |

| 6ES58972AE110KL1 | CACR-CSL12L18AAB | 61-0475-20 |

| 6ES58956SE030UG4 | CACR-TS555Z1SRY9 | 60-0377-02 |

| 6ES5895-6SC11 | CACR-SR03TZ0SFY01A | EPC-26A |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218