SANYO DENKI P60B13200HBV00交流电伺服电机

1.产 品 资 料 介 绍:

- SANYO DENKI P60B13200HBV00 是中功率交流电伺服电机,额定功率 2.0kW、额定转速 2000rpm,扭矩输出达 9.55N・m,动力强劲且稳定,适合中型数控机床主轴、自动化生产线重型传动机构等对动力要求较高的工业场景。

- 5-8 台该电机可通过工业总线实现协同控制,驱动生产线多工位重型执行部件,比如汽车底盘焊接线的翻转机构,能精准同步各翻转单元的转速与角度,确保焊接点位精准对齐,提升焊接合格率至 99% 以上。

- 适配三相 200V-230V 工业标准电源,电源接口采用防误插卡扣设计,可直接接入工厂现有供电回路,输入电压波动允许范围 ±10%,能适应车间供电电压的轻微波动,无需额外配置稳压设备。

- 采用轴径 28mm 的加粗输出轴设计,轴端硬度达 HRC55,抗磨损与抗冲击能力强,可直接适配大负载联轴器或齿轮箱,无需额外加固轴端,适配重型传动系统的使用需求。

- 能与同品牌 60 系列伺服放大器(如 60BA150VFW00)快速兼容,通过放大器的 “电机自动识别” 功能,可一键读取电机参数并完成校准,避免人工调试误差,调试时间缩短至 30 分钟以内。

- 内置 2500 线高精度增量式编码器,配合放大器的高频采样技术(采样频率 1MHz),可实时捕捉电机转速与位置变化,位置控制重复精度达 ±0.005mm,满足精密加工设备对定位精度的严苛需求。

- 优化的转子磁路设计降低了转动惯量,电机启停响应速度快,从静止到额定转速的启动时间仅需 0.25 秒,适合需要频繁切换运行状态的间歇式生产场景,如数控机床的快速换刀工序。

- 机身防护等级达 IP54,外壳接缝处采用耐油丁腈橡胶密封,输出轴端配备双唇密封圈,能有效阻挡车间粉尘、切削液与润滑油的侵入,适应机械加工车间多油污、多粉尘的复杂环境。

- 定子绕组选用 H 级耐高温漆包线,配合内置温度传感器的过热保护功能,当绕组温度超过 155℃时自动触发保护,避免因过热导致电机烧毁,延长电机使用寿命至 12000 小时以上。

- 整体在高功率输出、精准控制与耐用性上表现突出,无论是单台用于中型加工设备主轴,还是 8 台左右批量部署于重型自动化生产线,都能为工业自动化生产提供持续可靠的动力支持。

SANYO DENKI P60B13200HBV00交流电伺服电机 英文资料:

SANYO DENKI P60B13200HBV00 is a medium power AC servo motor with a rated power of 2.0kW, a rated speed of 2000rpm, and a torque output of 9.55N · m. It has strong and stable power and is suitable for industrial scenarios with high power requirements such as medium-sized CNC machine tool spindles and heavy-duty transmission mechanisms in automated production lines.

5-8 of these motors can be collaboratively controlled through an industrial bus to drive heavy-duty execution components at multiple workstations on a production line, such as the flipping mechanism of an automotive chassis welding line. They can accurately synchronize the speed and angle of each flipping unit, ensuring precise alignment of welding points and improving the welding qualification rate to over 99%.

Compatible with three-phase 200V-230V industrial standard power supply, the power interface adopts anti misoperation card buckle design, which can be directly connected to the existing power supply circuit of the factory. The allowable range of input voltage fluctuation is ± 10%, which can adapt to slight fluctuations in the workshop power supply voltage without the need for additional voltage stabilization equipment.

Adopting a thickened output shaft design with a diameter of 28mm, the shaft end hardness reaches HRC55, with strong wear and impact resistance, and can be directly adapted to large load couplings or gearboxes without the need for additional reinforcement of the shaft end, meeting the needs of heavy-duty transmission systems.

It can be quickly compatible with 60 series servo amplifiers of the same brand (such as 60BA150VFW00). Through the amplifier's "motor automatic recognition" function, motor parameters can be read and calibrated with one click, avoiding manual debugging errors and shortening debugging time to less than 30 minutes.

Built in 2500 line high-precision incremental encoder, combined with high-frequency sampling technology of amplifier (sampling frequency 1MHz), can capture motor speed and position changes in real time, with a position control repeatability of ± 0.005mm, meeting the strict requirements of precision machining equipment for positioning accuracy.

The optimized rotor magnetic circuit design reduces the moment of inertia, and the motor has a fast start stop response speed. The start-up time from static to rated speed only takes 0.25 seconds, making it suitable for intermittent production scenarios that require frequent switching of operating states, such as the fast tool changing process of CNC machine tools.

The body protection level reaches IP54, and the joint of the shell is sealed with oil resistant nitrile rubber. The output shaft end is equipped with a double lip sealing ring, which can effectively block the invasion of workshop dust, cutting fluid and lubricating oil, and adapt to the complex environment of mechanical processing workshop with multiple oil stains and dust.

The stator winding uses H-grade high-temperature resistant enameled wire, combined with the built-in temperature sensor's overheat protection function. When the winding temperature exceeds 155 ℃, the protection is automatically triggered to avoid motor burnout caused by overheating and extend the motor's service life to more than 12000 hours.

The overall performance is outstanding in high power output, precise control, and durability. Whether it is a single spindle used for medium-sized processing equipment or a batch deployment of about 8 on heavy-duty automation production lines, it can provide continuous and reliable power support for industrial automation production.

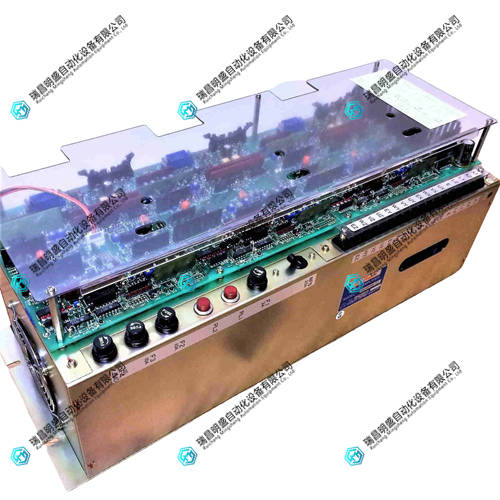

SANYO DENKI P60B13200HBV00交流电伺服电机 产品展示

产品视频

3.其他产品

SIEMENS 6ES7313-6CG04-0AB0 紧凑型网络卡

FOXBORO RH922VU输出通信模块

Woodward 5501-412模拟 I/O 模块

4.其他英文产品

ABB RTU560 560CMD11 communication unit

EKF ETH4 CN4-BELL Ethernet Controller

Foxboro FBM232 P0926GW Ethernet Communication Module

| 6ES5552-3UA11 | CACR-SR03SZ1SS-Y223, | Asyst 3200-1225-05 |

| 6ES5530-3LA12 | CACR-CSL15DAAA | Asyst 3200-4348-02 |

| 6ES5526-3LG11 | CACR-SR15BE12G-C | C2133 ASYST INC 3200-1045-01 3200-1065-01 |

| 6ES5524-3UA13 | CACR-IR1515FC | Asyst 3200-1101-02 |

| 6ES5521-8MA22 | CACR-TS111Z1SR, | Asyst 3200-1251-02 |

| 6ES5521-8MA21 | CACR-SR20BF1AM | 061-06039-0003 |

| 6ES5513-3LB11 | CACR-IR-USED | 60-0401-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218