SANYO DENKI A7-1-10047-1E伺服驱动控制器

1.产 品 资 料 介 绍:

- SANYO DENKI A7-1-10047-1E 是紧凑型伺服驱动控制器,额定输出电流 10A,适配 0.75kW-1.5kW 的伺服电机,主打高性价比与精准控制,适合小型数控机床、电子元件装配机等对驱动精度有要求的轻中型工业场景。

- 8-12 台该控制器可通过 RS485 通讯总线实现协同控制,驱动生产线的多轴传动部件,比如手机外壳加工线的多工位打磨机构,能同步各工位打磨转速与进给速度,确保外壳表面粗糙度一致,提升产品合格率至 98% 以上。

- 适配单相 / 三相 200V-230V 工业标准电源,输入电压适应范围宽(170V-264V),可兼容不同地区工厂的供电规格,无需额外配置变压设备,降低跨区域生产设备部署的成本。

- 采用导轨式安装设计,厚度仅 45mm,可密集安装于标准电气控制柜内,1.2 米长的导轨可同时安装 15 台以上,大幅节省控制柜空间,适配设备密集型生产线的电气布局需求。

- 能与同品牌 P 系列伺服电机(如 P50B08100DCVT2)快速兼容,支持 “参数一键复制” 功能,通过专用数据线可将一台调试完成的控制器参数批量导入其他设备,调试效率提升 60% 以上。

- 支持位置、速度、扭矩三种控制模式,位置控制时脉冲输入频率达 200kHz,配合电子齿轮功能,可实现细分精度控制,满足微型元件装配时的微米级定位需求。

- 内置过流、过压、过载、欠压、过热五种保护功能,故障发生时会实时点亮对应报警指示灯,并通过通讯接口上传故障代码,工作人员可通过配套软件快速查询故障原因,停机排查时间缩短至 10 分钟以内。

- 优化的能耗控制算法,电机轻载时自动降低输出电流,相比传统驱动控制器能耗降低 12%-18%,10 台批量使用时,每年可帮助企业节省约 2000 度电,符合绿色生产需求。

- 配备高清 LCD 显示面板,可实时显示电机转速、电流、位置等运行参数,支持中文 / 英文双语切换,操作界面直观易懂,新手也能快速上手设置参数,降低人员培训成本。

- 整体在兼容性、节能性与操作便利性上表现突出,无论是单台驱动小型加工设备,还是 10 台以上批量部署于电子、轻工行业生产线,都能为伺服系统提供稳定可靠的驱动控制支持。

SANYO DENKI A7-1-10047-1E伺服驱动控制器 英文资料:

SANYO DENKI A7-1-10047-1E is a compact servo drive controller with a rated output current of 10A, suitable for servo motors ranging from 0.75kW to 1.5kW. It emphasizes high cost-effectiveness and precise control, and is suitable for small CNC machine tools, electronic component assembly machines, and other light and medium-sized industrial scenarios that require drive accuracy.

8-12 units of this controller can achieve collaborative control through RS485 communication bus, driving multi axis transmission components of the production line, such as the multi station polishing mechanism of the mobile phone shell processing line. It can synchronize the polishing speed and feed rate of each station, ensure consistent surface roughness of the shell, and improve the product qualification rate to over 98%.

Suitable for single-phase/three-phase 200V-230V industrial standard power supply, with a wide range of input voltage adaptation (170V-264V), compatible with power supply specifications of factories in different regions, without the need for additional transformer equipment, reducing the cost of cross regional production equipment deployment.

Adopting a guide rail installation design with a thickness of only 45mm, it can be densely installed in standard electrical control cabinets. The 1.2-meter-long guide rail can install more than 15 units at the same time, greatly saving control cabinet space and adapting to the electrical layout requirements of equipment intensive production lines.

It can be quickly compatible with P series servo motors of the same brand (such as P50B08100DCVT2), supports the "one click parameter copying" function, and can batch import the parameters of a debugged controller into other devices through a dedicated data cable, improving debugging efficiency by more than 60%.

Supports three control modes: position, speed, and torque. During position control, the pulse input frequency reaches 200kHz. Combined with electronic gear function, it can achieve subdivision accuracy control and meet the micro level positioning requirements during micro component assembly.

Built in overcurrent, overvoltage, overload, undervoltage, and overheating protection functions. When a fault occurs, the corresponding alarm indicator light will be lit in real time, and the fault code will be uploaded through the communication interface. The staff can quickly query the cause of the fault through the supporting software, and the downtime for troubleshooting can be shortened to less than 10 minutes.

The optimized energy consumption control algorithm automatically reduces the output current when the motor is under light load, reducing energy consumption by 12% -18% compared to traditional drive controllers. When 10 units are used in bulk, it can help enterprises save about 2000 kWh of electricity per year, which meets the needs of green production.

Equipped with a high-definition LCD display panel, it can display real-time operating parameters such as motor speed, current, and position. It supports bilingual switching between Chinese and English, and the operation interface is intuitive and easy to understand. Even beginners can quickly set parameters, reducing personnel training costs.

The overall performance is outstanding in terms of compatibility, energy efficiency, and operational convenience. Whether it is a single drive small processing equipment or a batch deployment of more than 10 units on production lines in the electronics and light industry, it can provide stable and reliable drive control support for servo systems.

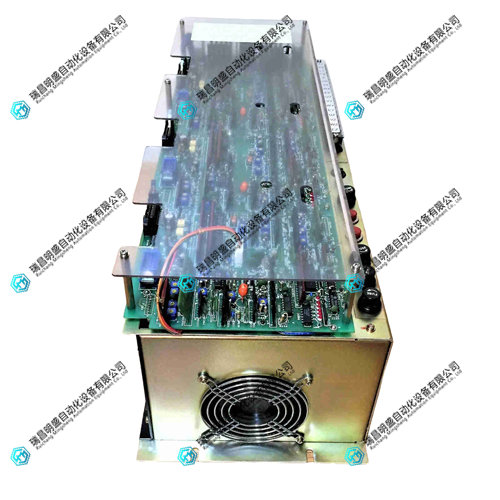

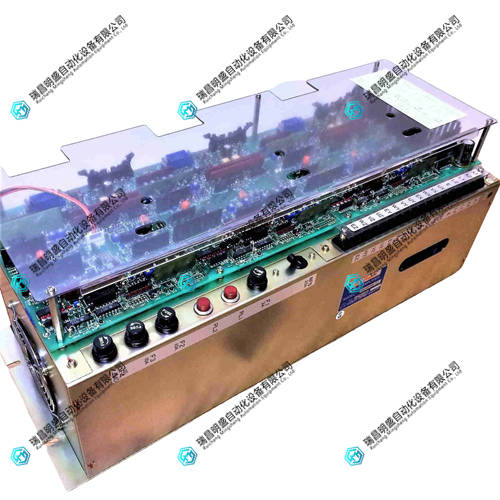

SANYO DENKI A7-1-10047-1E伺服驱动控制器 产品展示

产品视频

3.其他产品

SIEMENS 6ES7313-6CG04-0AB0 紧凑型网络卡

FOXBORO RH922VU输出通信模块

Woodward 5501-412模拟 I/O 模块

4.其他英文产品

ABB RTU560 560CMD11 communication unit

EKF ETH4 CN4-BELL Ethernet Controller

Foxboro FBM232 P0926GW Ethernet Communication Module

| 6ES5552-3UA11 | CACR-SR03SZ1SS-Y223, | Asyst 3200-1225-05 |

| 6ES5530-3LA12 | CACR-CSL15DAAA | Asyst 3200-4348-02 |

| 6ES5526-3LG11 | CACR-SR15BE12G-C | C2133 ASYST INC 3200-1045-01 3200-1065-01 |

| 6ES5524-3UA13 | CACR-IR1515FC | Asyst 3200-1101-02 |

| 6ES5521-8MA22 | CACR-TS111Z1SR, | Asyst 3200-1251-02 |

| 6ES5521-8MA21 | CACR-SR20BF1AM | 061-06039-0003 |

| 6ES5513-3LB11 | CACR-IR-USED | 60-0401-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218