SANYO DENKI PQMOPA16001伺服驱动器

1.产 品 资 料 介 绍:

- SANYO DENKI PQMOPA16001 是中功率伺服驱动器,额定输出电流 16A,适配 1.5kW-2.5kW 的伺服电机,主打高响应性与稳定驱动,适合中型数控机床进给轴、自动化生产线重型传动机构等对动力与响应速度有要求的工业场景。

- 6-10 台该驱动器可通过 EtherCAT 工业总线实现高速协同控制,驱动生产线多轴联动部件,比如新能源电池极片裁切机的多轴送料机构,能同步各轴送料速度与裁切节奏,确保极片尺寸公差控制在 ±0.02mm 内,提升裁切合格率至 99.5% 以上。

- 适配三相 200V-230V 工业标准电源,输入电压波动允许范围 ±15%(170V-265V),可适应工厂供电电压的较大波动,无需额外配置稳压设备,降低复杂供电环境下的设备部署成本。

- 采用壁挂式 + 模块化设计,核心驱动单元与控制单元独立封装,后期维护时可单独拆卸更换故障单元,无需整体拆解驱动器,维修时间缩短至 20 分钟以内,减少生产线停机损失。

- 能与同品牌 P 系列中功率伺服电机(如 P60B13200HBV00)无缝兼容,支持 “电机参数自动读取” 功能,通电后可自动识别电机型号并加载匹配参数,避免人工设置误差,调试效率提升 50% 以上。

- 支持位置、速度、扭矩、转矩限制四种控制模式,位置控制时脉冲响应频率达 1MHz,配合高精度电子凸轮功能,可实现复杂轨迹运动控制,满足异形零件加工时的曲线进给需求。

- 内置过流、过压、过载、欠压、过热、编码器故障六种保护功能,故障发生时会立即切断输出并触发声光报警,同时将故障信息存储至本地内存,工作人员通过配套诊断软件可回溯故障前 30 秒运行数据,快速定位问题根源。

- 搭载 “能量回馈” 技术,电机减速或制动时产生的再生电能可高效回馈至电网,相比传统驱动器能耗降低 20%-25%,10 台批量使用时,每年可帮助企业节省约 3500 度电,符合工业节能降耗要求。

- 配备 5 英寸彩色触控屏,可实时显示电机转速、电流、位置、故障代码等 20 + 项运行参数,支持自定义参数显示界面,同时具备参数加密功能,防止非授权人员误修改关键设置,保障设备运行稳定性。

- 整体在高响应控制、兼容性与节能性上表现突出,无论是单台驱动中型加工设备,还是 10 台左右批量部署于重型自动化生产线,都能为伺服系统提供高效可靠的驱动支持。

SANYO DENKI PQMOPA16001伺服驱动器 英文资料:

SANYO DENKI PQMOPA16001 is a medium power servo drive with a rated output current of 16A, suitable for servo motors ranging from 1.5kW to 2.5kW. It focuses on high responsiveness and stable driving, and is suitable for industrial scenarios such as feed shafts for medium-sized CNC machine tools and heavy-duty transmission mechanisms for automated production lines that require power and response speed.

6-10 units of this driver can achieve high-speed collaborative control through EtherCAT industrial bus, driving multi axis linkage components of the production line, such as the multi axis feeding mechanism of the new energy battery electrode cutting machine, which can synchronize the feeding speed and cutting rhythm of each axis, ensuring that the electrode size tolerance is controlled within ± 0.02mm, and improving the cutting pass rate to over 99.5%.

Suitable for three-phase 200V-230V industrial standard power supply, with an allowable range of input voltage fluctuation of ± 15% (170V-265V), it can adapt to large fluctuations in factory power supply voltage without the need for additional voltage stabilization equipment, reducing equipment deployment costs in complex power supply environments.

Adopting wall mounted and modular design, the core drive unit and control unit are independently packaged. During later maintenance, the faulty unit can be disassembled and replaced separately, without the need to disassemble the driver as a whole. The repair time is shortened to less than 20 minutes, reducing production line downtime losses.

It is seamlessly compatible with power servo motors of the same brand P series (such as P60B13200HV00), supports the "automatic reading of motor parameters" function, and can automatically identify the motor model and load matching parameters after power on, avoiding manual setting errors and improving debugging efficiency by more than 50%.

Supports four control modes: position, speed, torque, and torque limit. The pulse response frequency during position control reaches 1MHz. Combined with high-precision electronic cam function, it can achieve complex trajectory motion control and meet the curve feed requirements during the processing of irregular parts.

Built in six protection functions: overcurrent, overvoltage, overload, undervoltage, overheating, and encoder failure. When a fault occurs, the output will be immediately cut off and an audible and visual alarm will be triggered. At the same time, the fault information will be stored in local memory. The staff can trace the operating data of the previous 30 seconds through the supporting diagnostic software to quickly locate the root cause of the problem.

Equipped with "energy feedback" technology, the regenerated electricity generated during motor deceleration or braking can be efficiently fed back to the power grid, reducing energy consumption by 20% -25% compared to traditional drives. When 10 units are used in bulk, it can help enterprises save about 3500 kWh of electricity per year, which meets the requirements of industrial energy conservation and consumption reduction.

Equipped with a 5-inch color touch screen, it can display more than 20 operating parameters such as motor speed, current, position, and fault codes in real time. It supports custom parameter display interface and also has parameter encryption function to prevent unauthorized personnel from accidentally modifying key settings, ensuring the stability of equipment operation.

The overall performance is outstanding in high response control, compatibility, and energy efficiency. Whether it is a single drive medium-sized processing equipment or a batch deployment of about 10 units on heavy-duty automated production lines, it can provide efficient and reliable drive support for servo systems.

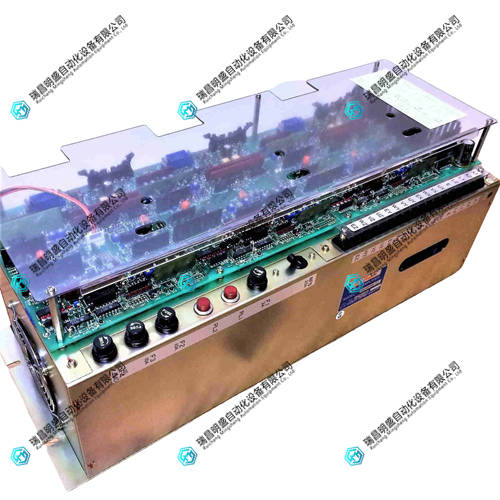

SANYO DENKI PQMOPA16001伺服驱动器 产品展示

产品视频

3.其他产品

SIEMENS 6ES7313-6CG04-0AB0 紧凑型网络卡

FOXBORO RH922VU输出通信模块

Woodward 5501-412模拟 I/O 模块

4.其他英文产品

ABB RTU560 560CMD11 communication unit

EKF ETH4 CN4-BELL Ethernet Controller

Foxboro FBM232 P0926GW Ethernet Communication Module

| 6ES5552-3UA11 | CACR-SR03SZ1SS-Y223, | Asyst 3200-1225-05 |

| 6ES5530-3LA12 | CACR-CSL15DAAA | Asyst 3200-4348-02 |

| 6ES5526-3LG11 | CACR-SR15BE12G-C | C2133 ASYST INC 3200-1045-01 3200-1065-01 |

| 6ES5524-3UA13 | CACR-IR1515FC | Asyst 3200-1101-02 |

| 6ES5521-8MA22 | CACR-TS111Z1SR, | Asyst 3200-1251-02 |

| 6ES5521-8MA21 | CACR-SR20BF1AM | 061-06039-0003 |

| 6ES5513-3LB11 | CACR-IR-USED | 60-0401-02 |

The content is from Ruichang Mingsheng Automation Equipment Co., LTD

Contact: +86 15270269218